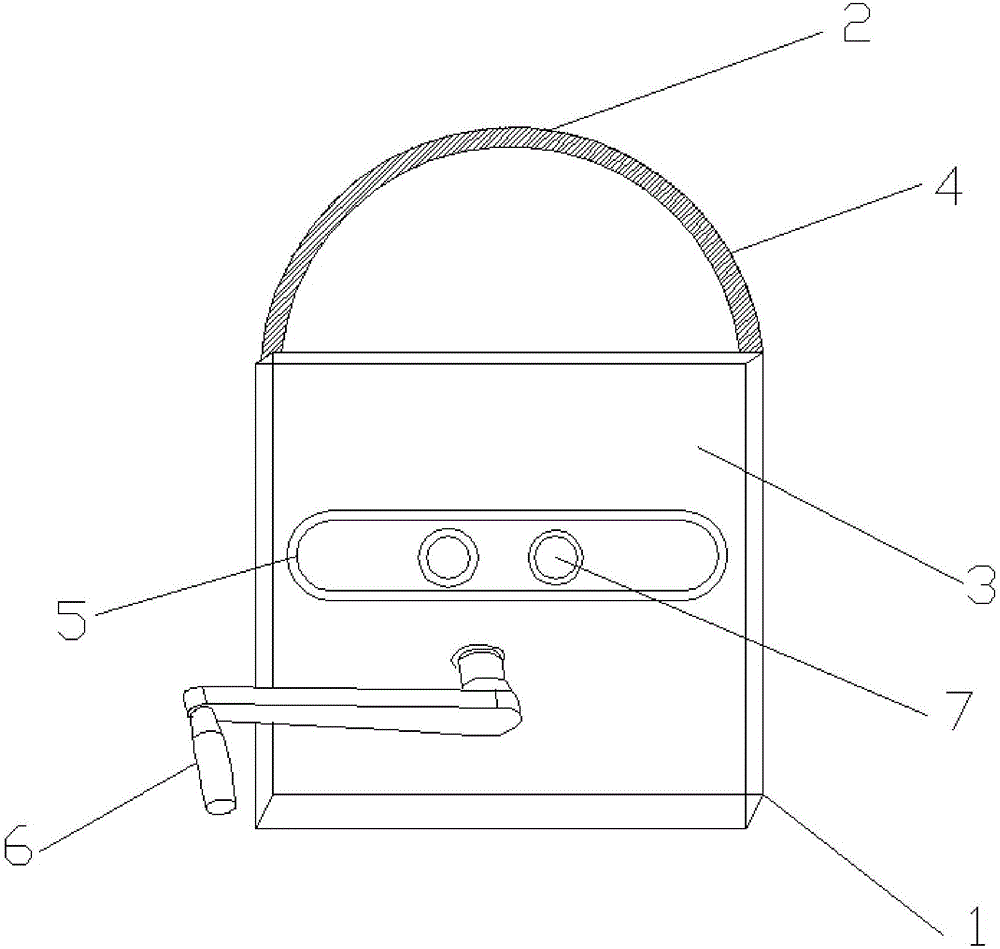

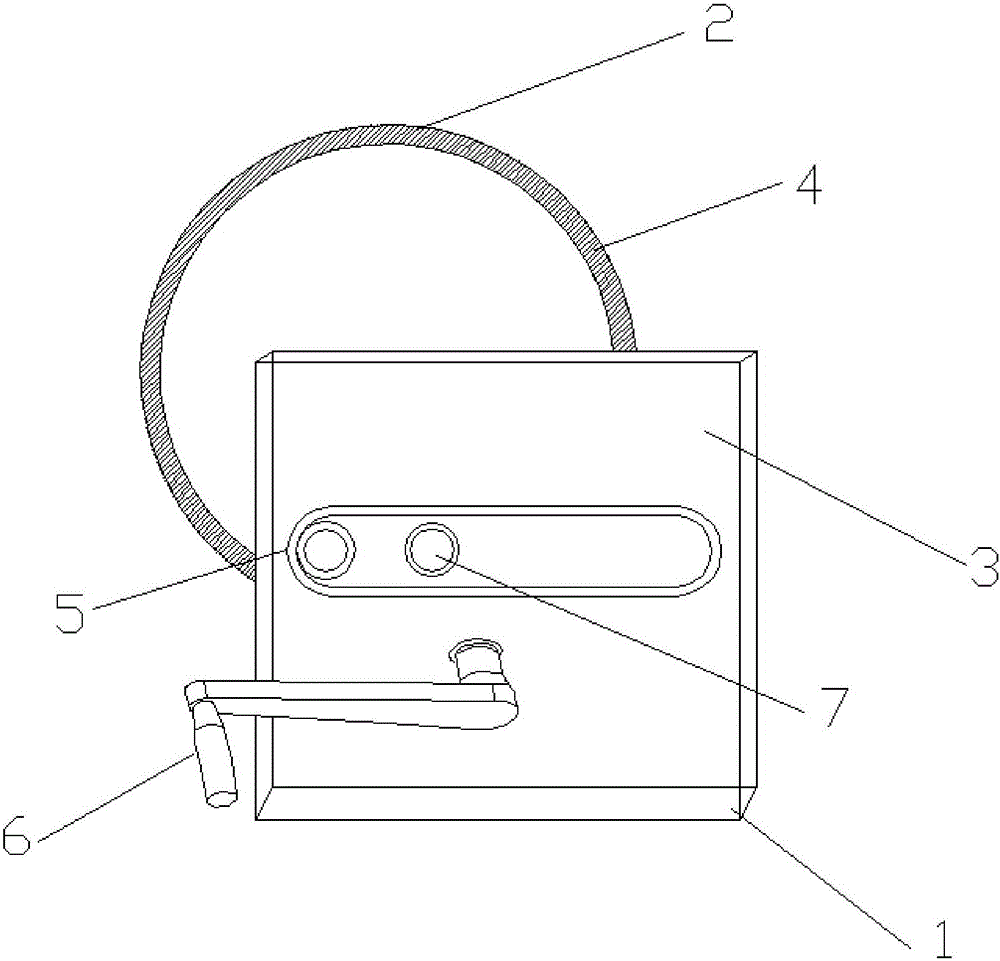

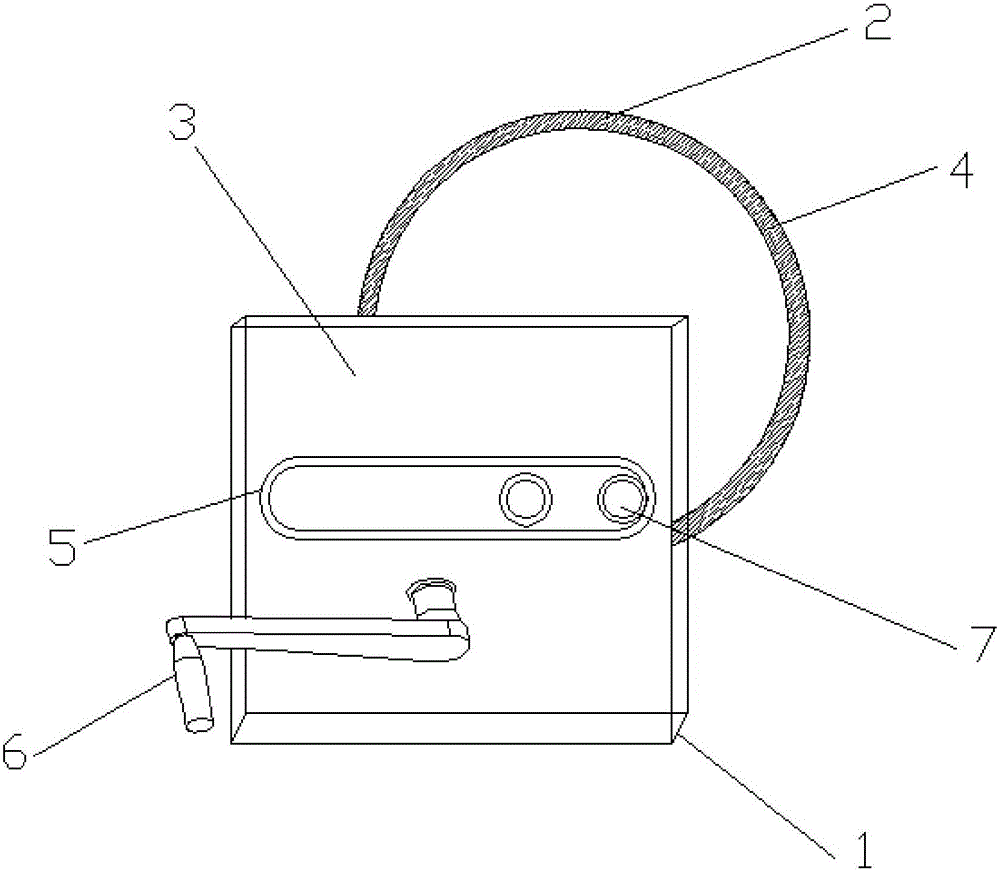

Sliding slot type cutter device

A cutting knife and chute technology, which is used in wood splitting devices, sawing equipment, portable motorized circular saws, etc., can solve the problems of prolonged cutting time, uneven cutting, tearing, etc., and achieves good cutting quality, low cost, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0044] When a user uses a chute-type cutter device of the present invention, when an object needs to be cut, the manual drive device 6 is used to shake or drive the cutter body 3 to be stressed, the guide groove 5 moves and / or the cutter body 3 moves, and when the guide groove 5 moves Provide a component force of lateral movement, the cutter body 3 moves or rotates laterally along the guide groove 5 at the same time when moving forward, and at the same time, the cutter body 3 provides a component force in the cutting direction when moving, and the manual drive device 6 can make the special-shaped When the blade 4 moves forward, it cuts at the same time. Therefore, when the user cuts the object to be cut, the object to be cut can be cut quickly and efficiently, and the cutting is clean.

[0045] For example, when a user cuts a tree branch, the hand crank device 6 is one of a hand-operated rocker, a swing rod, a cam, a hand crank, or a crawler. When the user moves by hand, the move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com