A chute type cutter structure

A cutting knife and chute technology, applied in metal sawing equipment, sawing machine tools, metal processing equipment, etc., can solve the problems of poor manual cutting quality, large processing workload, low production efficiency, etc., and achieve good cutting quality. , low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

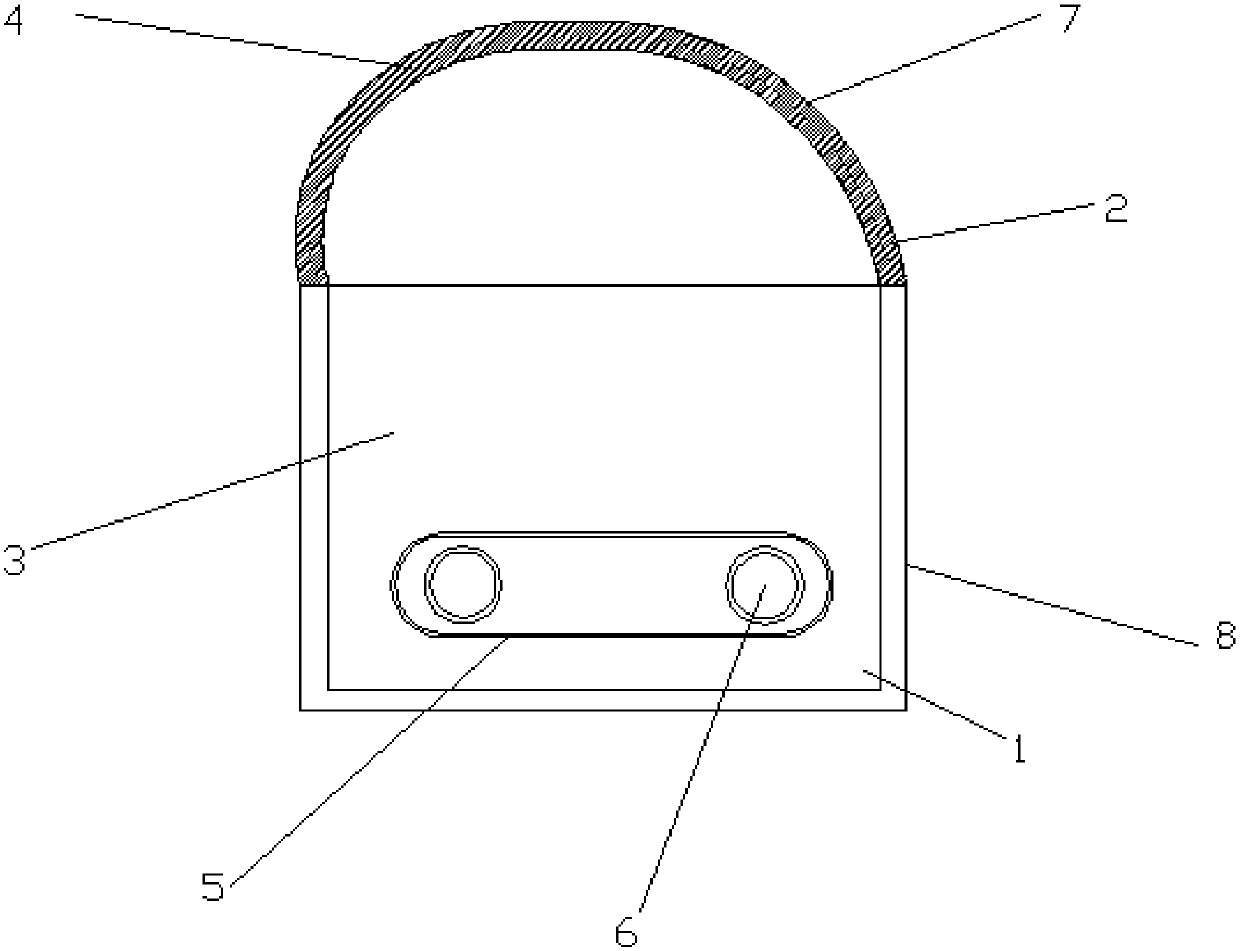

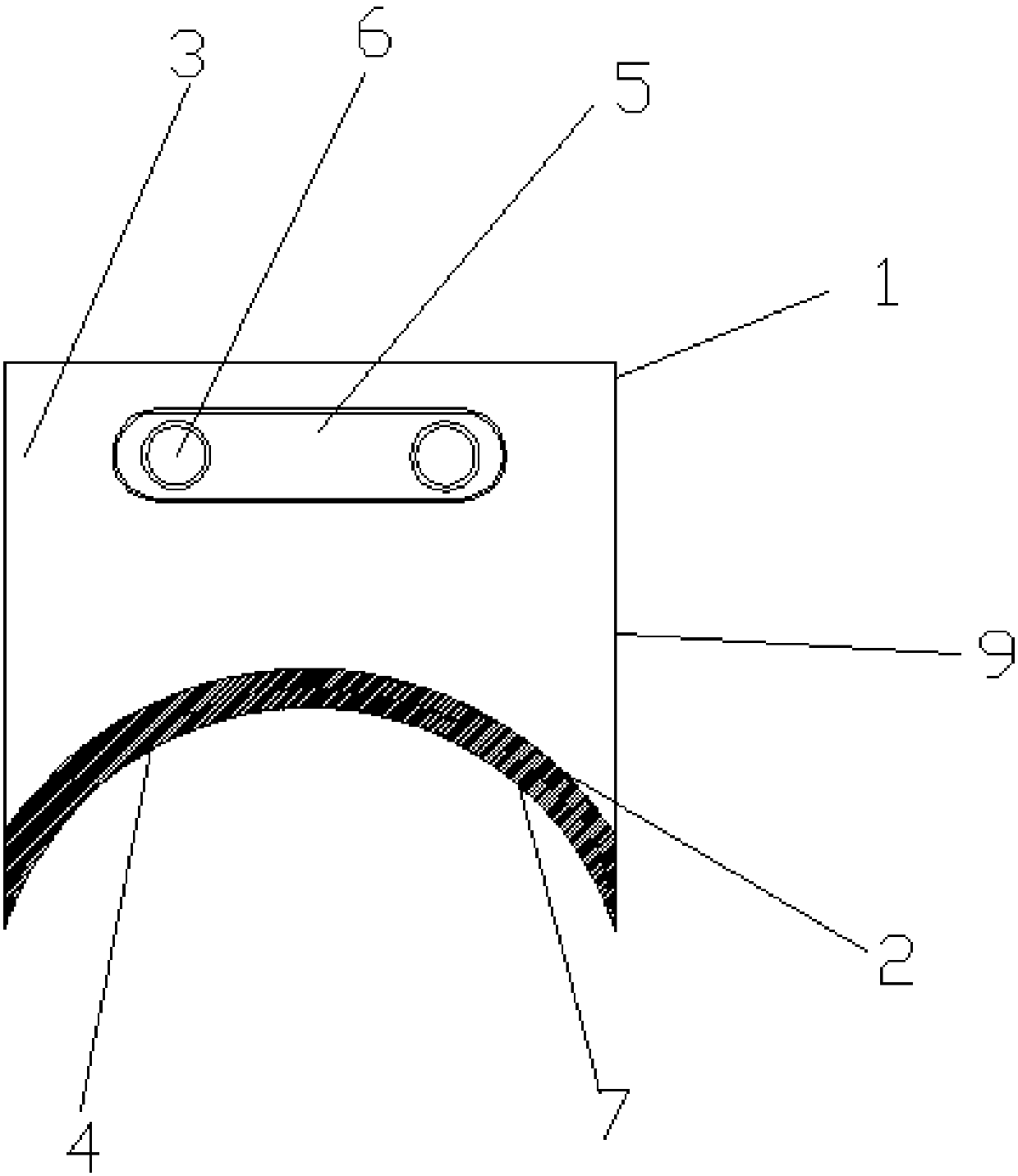

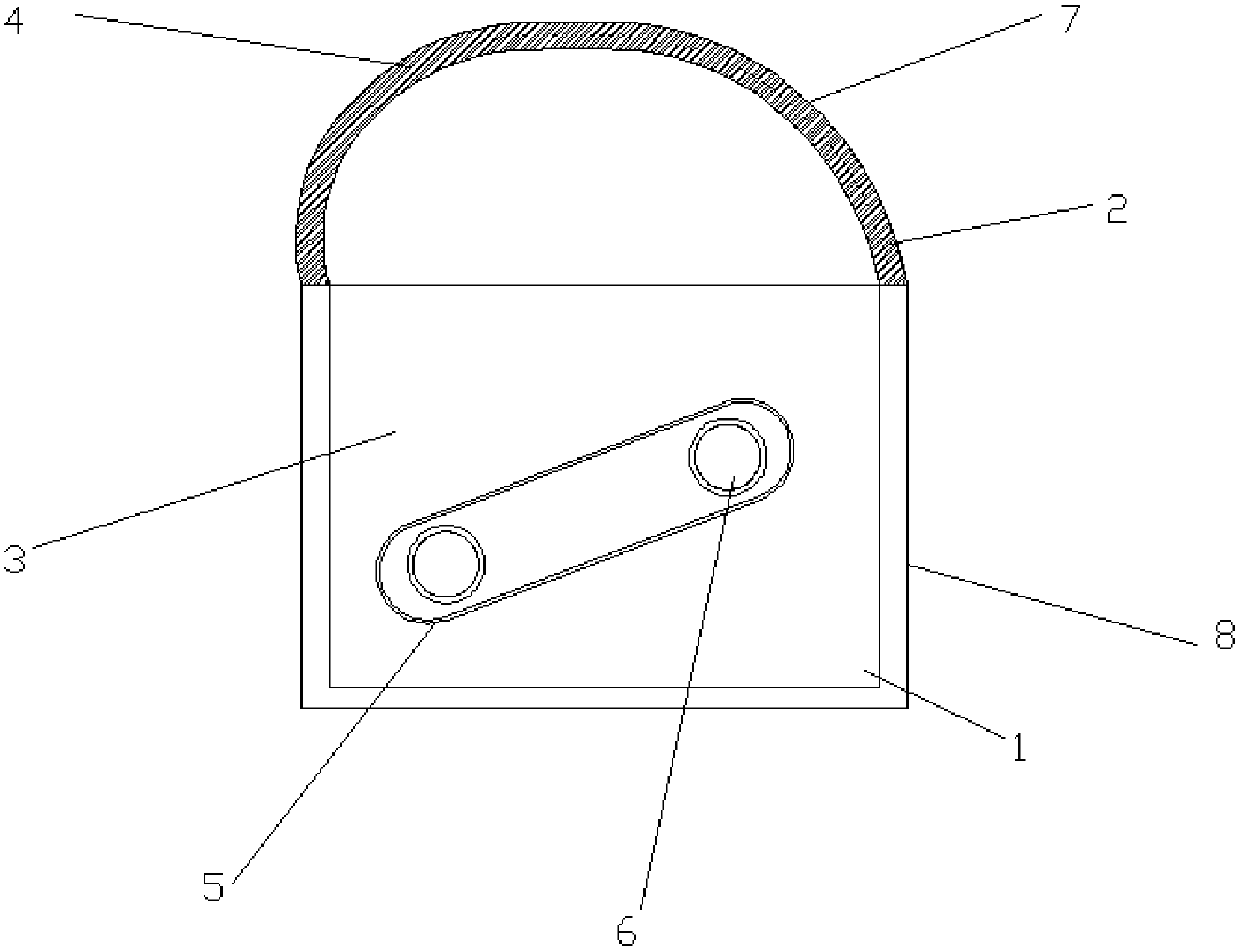

[0041] The user uses a chute-type cutting knife structure of the present invention to cut objects, because the knife body 3 is driven by an external force and generates a lateral force component along the guide groove 5, and the knife body 3 moves along the side of the guide groove 5 while advancing. Moving to the direction, while cutting and rotating at the same time, the object to be cut can be quickly cut clean without residue, labor-saving, and there is no need to spend a lot of power manually to use a knife to cut.

[0042] At the same time, when the guide groove 5 is driven by an external force, a component force in the cutting direction is generated. The external force pushes the guide groove 5 to slide, and drives the blade portion 2 of the cutter head 1 to slide while advancing. The special-shaped blade 4 can be replaced by an involute-shaped blade. Easy to cut. For example, when a user cuts a pipe object, the cutter body of this type of structure is driven by manpowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com