A saw blade structure

A technology of saw blades and cutter discs, which is applied to the knives of sawing machine devices, metal sawing equipment, metal processing equipment, etc. It can solve the problems that the cutting effect cannot be fine, the cutting can not be effective, and the cutting time is prolonged, so as to achieve convenient and efficient cutting. , Save time and effort, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

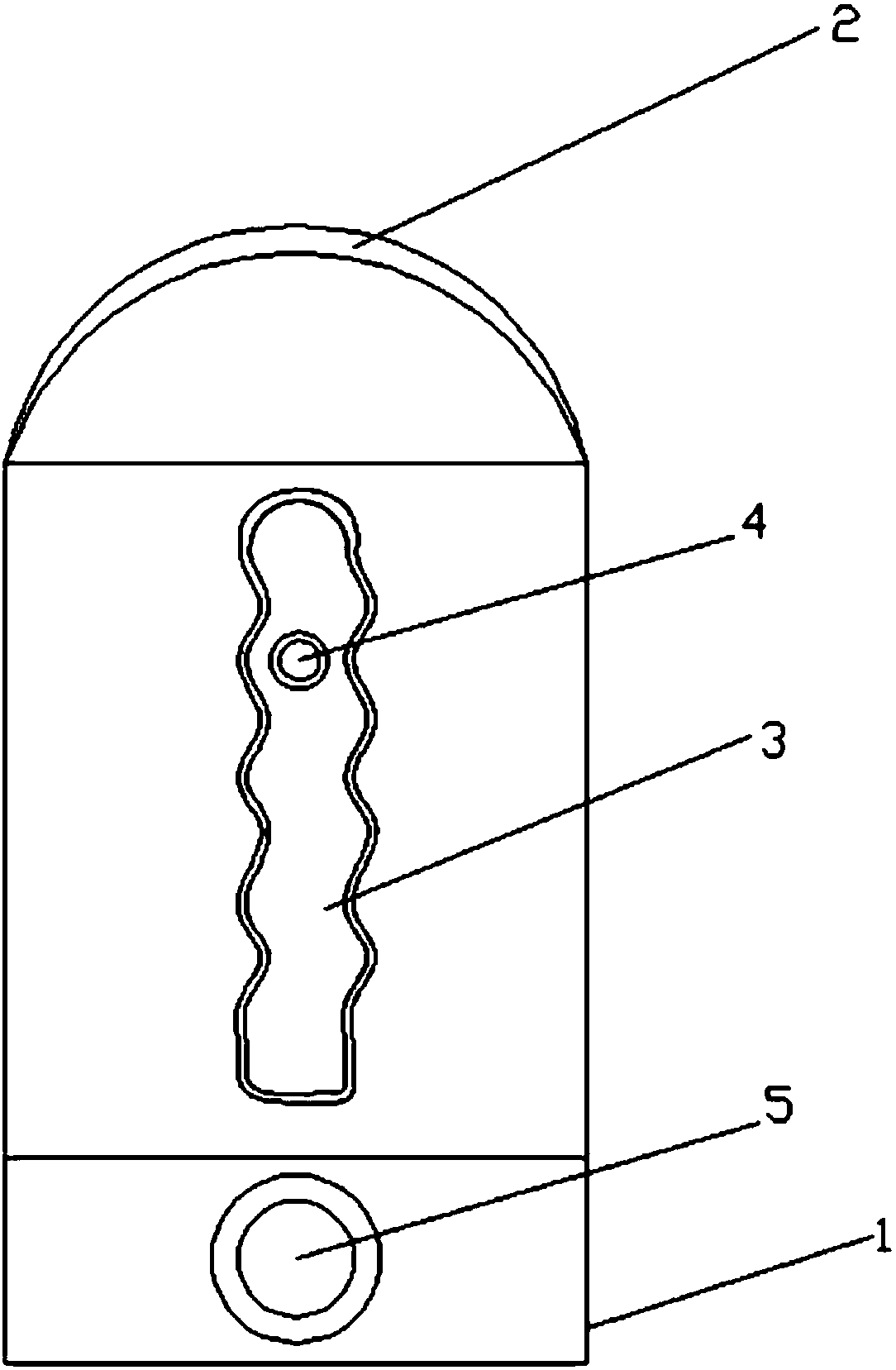

[0033] The user uses a saw blade structure of the present invention, the guide roller 4 slides in the guide groove 3, and the blade 2 slides or vibrates while cutting while cutting, and can generate a lateral component force and a cutting direction along the guide groove 4. Partial force, the cutter head 1 moves sideways or slides or vibrates along the guide groove 4 while cutting forward, the object to be cut can be cut quickly and effectively, the rotating shaft 5 can rotate around the cutter head 1, and drive along the guide groove 3 The cutter head 1 rotates and rocks around the rotation axis 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com