Adhesive sheet, dicing tape intergrated type adhesive sheet, and semiconductor device producing method

a technology of intergrated type and adhesive sheet, which is applied in the direction of heat-activated film/foil adhesive, film/foil adhesive, transportation and packaging, etc., can solve the problems of not being able to permit effective cutting of wafers and adhesive sheets, and achieve excellent adhesion reliability and effective cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

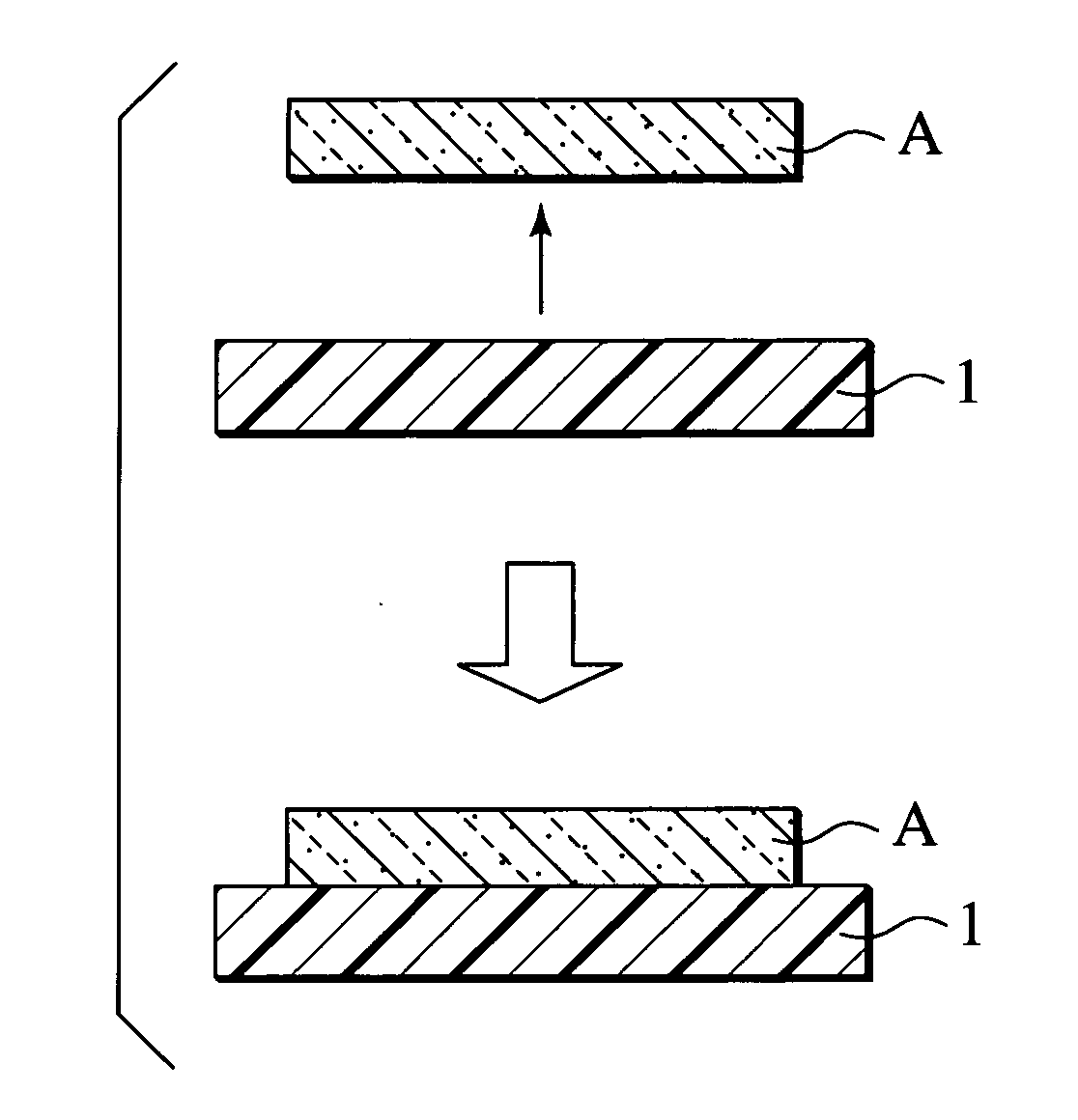

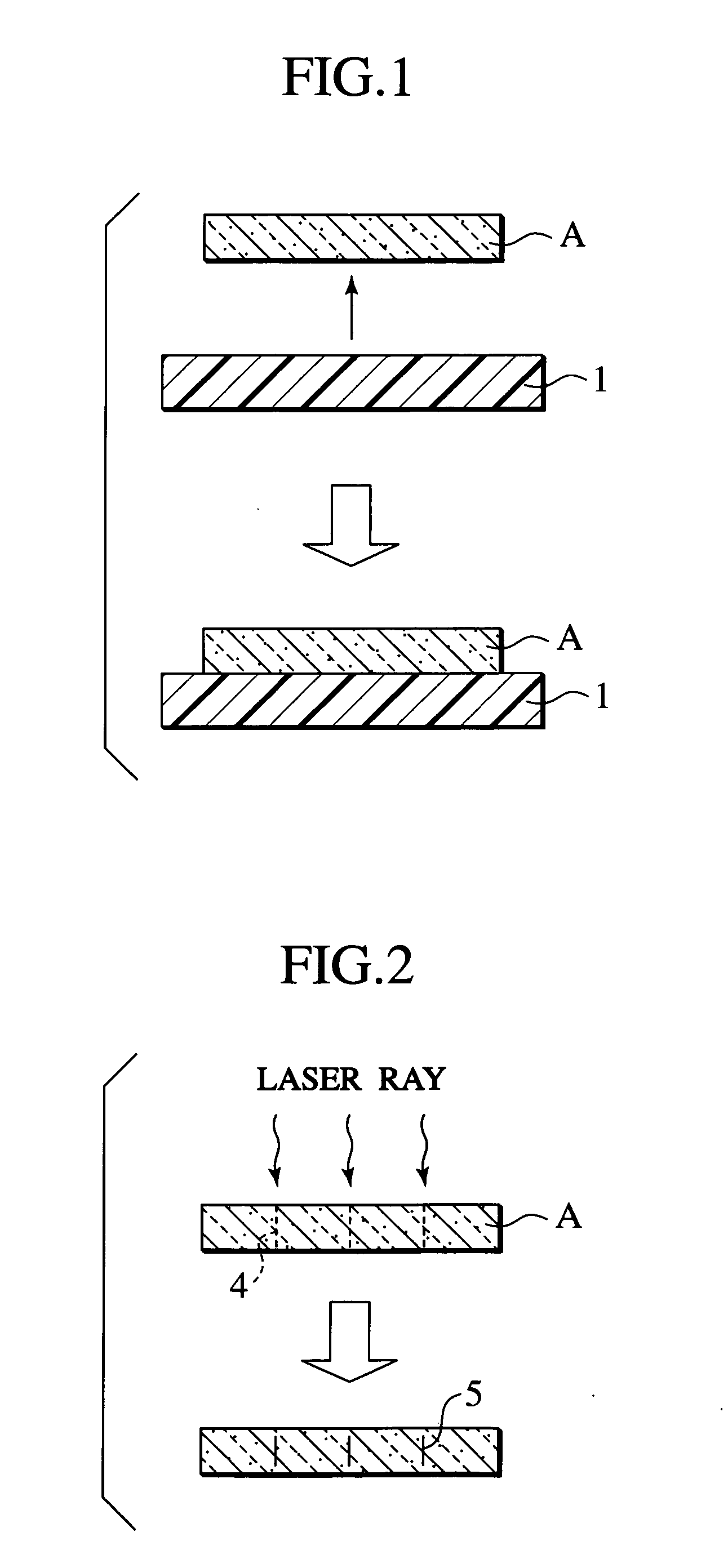

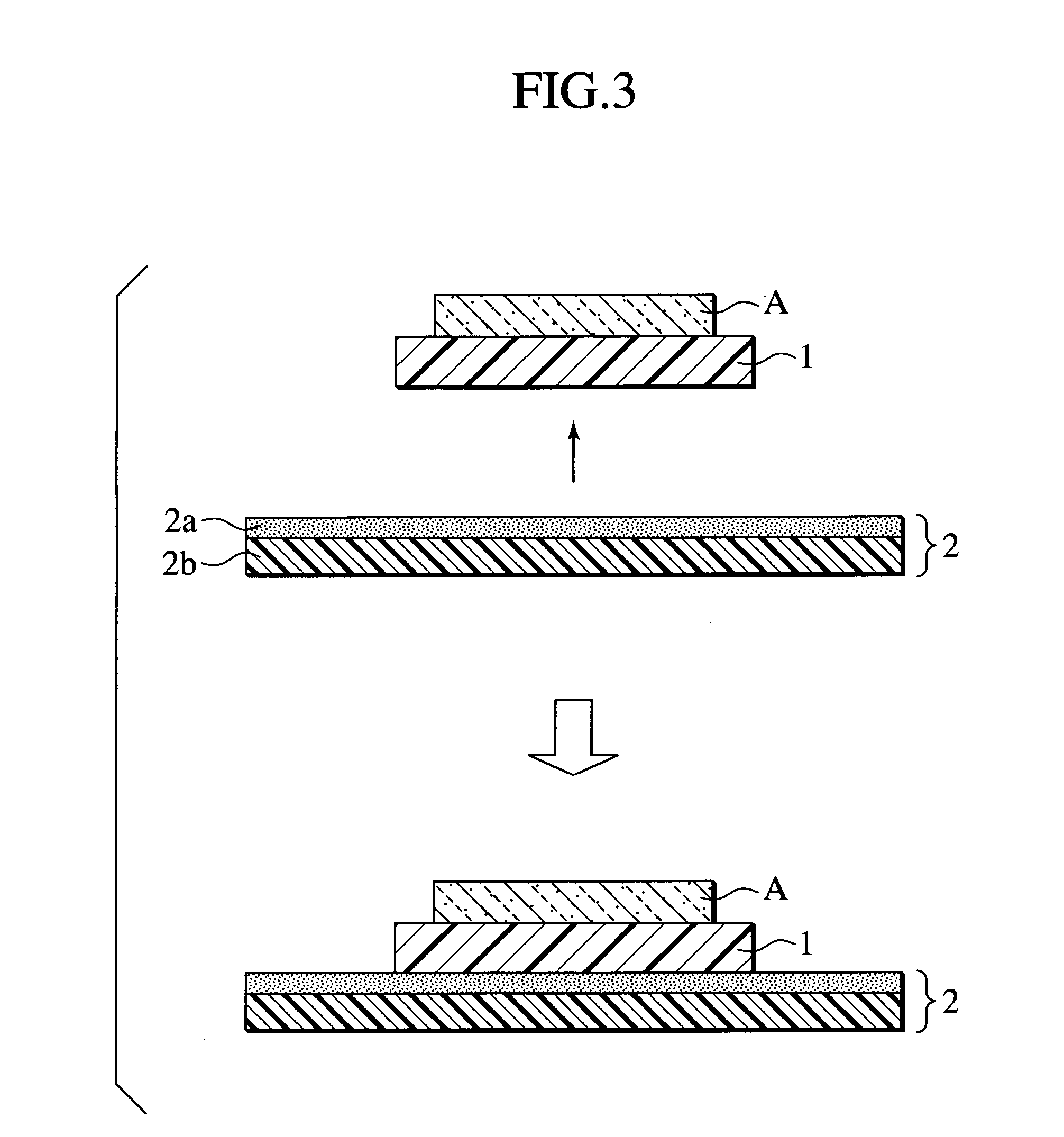

Method used

Image

Examples

example 1

[0105] Cyclohexanone was added to a composition composed of: 30 parts by weight of a bisphenol F type epoxy resin (trade name: YD-8170C, manufactured by Tohto Kasei Co., Ltd., epoxy equivalent: 160) and 10 parts by weight of a cresol novolak type epoxy resin (trade name: YDCN-703, manufactured by Tohto Kasei Co., Ltd., epoxy equivalent: 210) as epoxy resins; 27 parts by weight of a phenol novolak resin (trade name: Priophen LF2882, manufactured by Dainippon Ink & Chemicals, Inc.) as a curing agent for the epoxy resins; 28 parts by weight of an epoxy-group-containing acrylic rubber (trade name: HTR-860P-3DR, manufactured by Nagase Chemtex Corp.; weight-average molecular weight based on gel permeation chromatography: 800000, glycidyl methacrylate: 3% by weight, and Tg: −7° C.) as an epoxy-group-containing acrylic copolymer; 0.1 part by weight of an imidazole curing accelerator (Curezol, manufactured by Shikoku Chemicals Corp.) as a curing accelerator; 95 parts by weight of a silica fi...

examples 2 to 6

[0107] About respective compositions shown in Table 1, adhesive sheets were produced in the same way as in Example 1. The adhesive sheet of Example 6 was an adhesive sheet obtained by subjecting the sheet of Example 1 to heat treatment at 40° C. for 24 hours, thereby lowering the breaking elongation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com