Sheet/branch silver-coated copper powder and green halogen-free low-silver-content economical electrically conductive adhesive capable of replacing traditional electrically conductive adhesives with high silver contents

A silver-plated copper powder and flake technology, which is applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems of weak bonding between silver plating and copper powder, low conductivity, low oxidation resistance, and silver powder washing. Collect troubles and other problems, achieve good intrinsic conductivity, good thermal conductivity, and increase the effect of electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

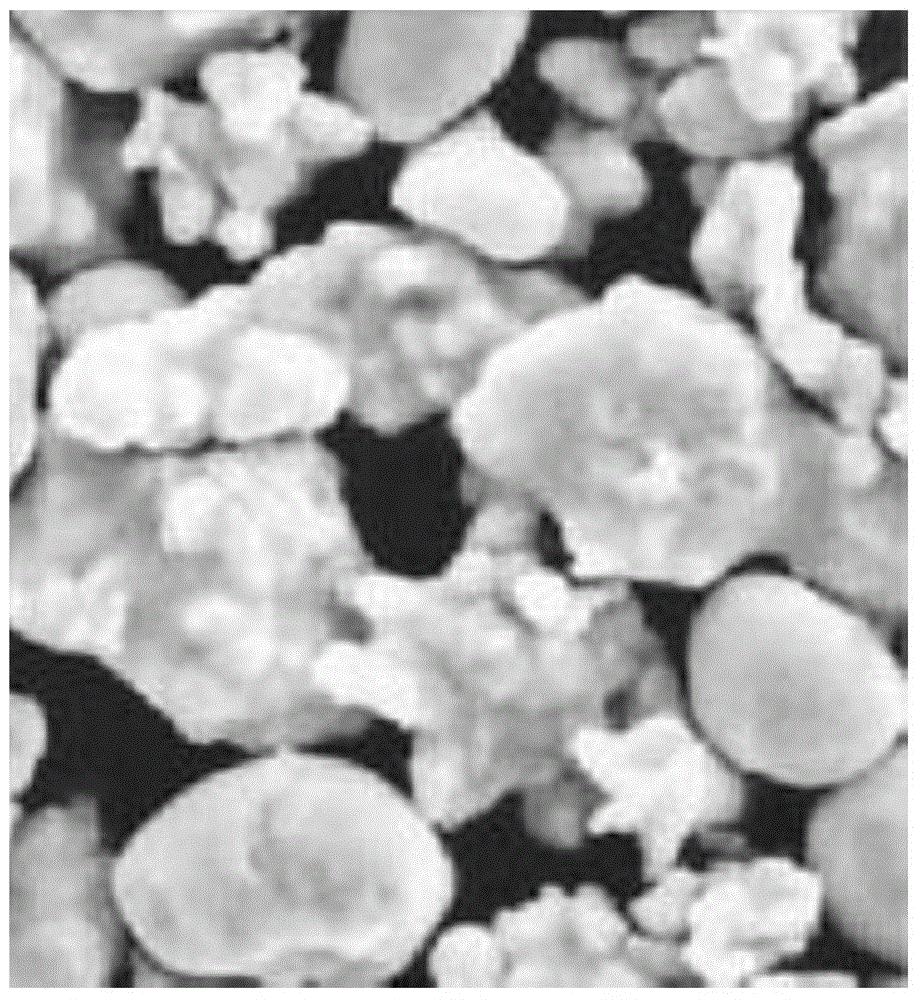

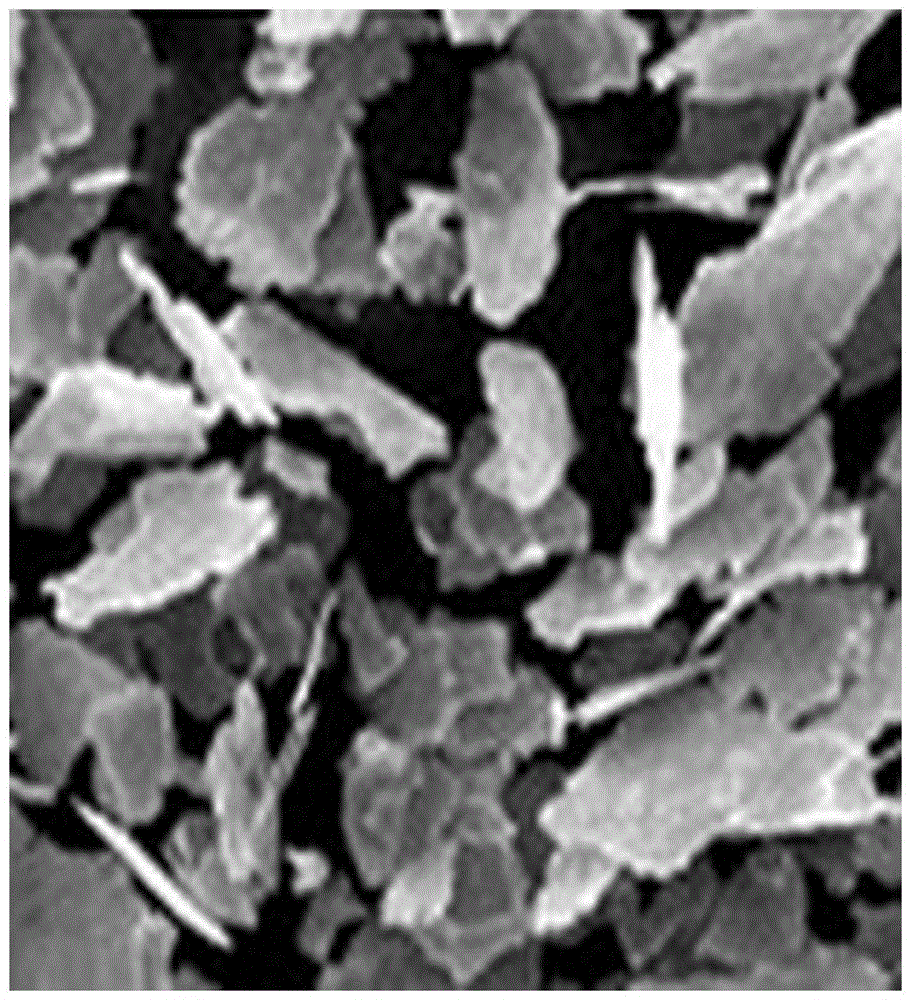

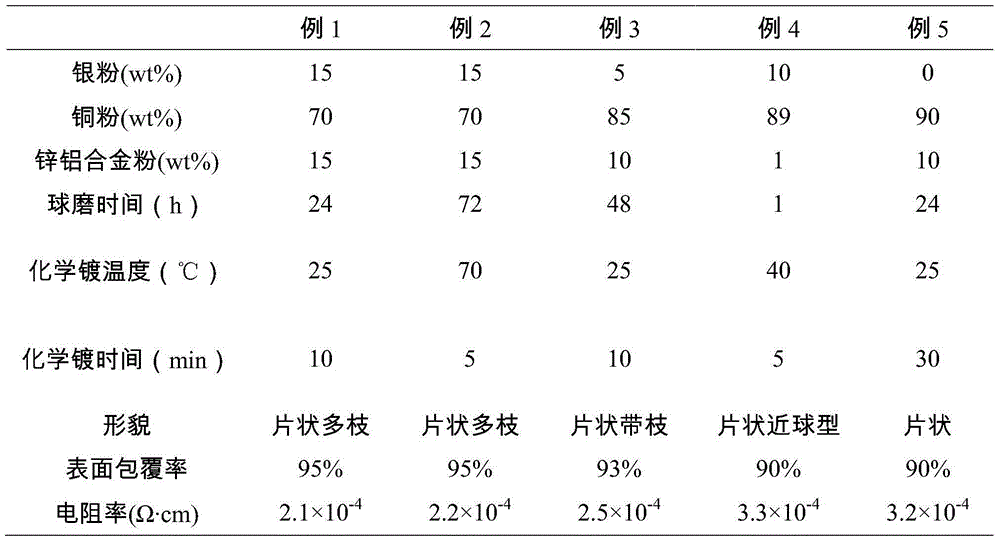

[0049] The preparation of embodiment 1-5 silver-plated copper powder:

Embodiment 1

[0050] Example 1: (1) 15g of silver powder, 70g of copper powder, and 15g of zinc-aluminum alloy powder were placed in a high-energy ball mill and ball-milled for 24 hours to obtain 100g of diffusion-type pre-alloyed copper powder. Among them: the particle size of copper powder>the particle size of silver powder≥the particle size of Zn-Al alloy powder, and the aluminum content of Zn-Al alloy powder is 1-3wt%.

[0051] (2) Take 100g of alloyed copper powder in step (1), wash in acetone for 15 minutes under ultrasonic stirring conditions, wash in 3% dilute sulfuric acid for 2 minutes, wash with deionized water three times, filter the water and set aside.

[0052] (3) Electroless plating solution composition: main salt (silver nitrate 25g / L), reducing agent (formaldehyde 20g / L), complexing agent (EDTA30g / L), stabilizer (bipyridine 30mg / L), foaming agent ( PEG 5 μg / L), use ammonia water to adjust the pH value to 11, add the alloy copper powder processed in step (2), ultrasonic ele...

Embodiment 2-5

[0056] Silver-plated copper powder was prepared with reference to the method of Example 1.

[0057] Wherein in embodiment 2,

[0058] Step (3) is: chemical plating bath composition: soluble silver salt silver nitrate: 10g / L, reducing agent: formaldehyde 5g / L, complexing agent: EDTA10g / L, stabilizer: bipyridine 10mg / L, foaming agent: PEG 1 μg / L. Utilize ammonia water to adjust the pH value to 10, add the alloy copper powder treated in step (2), perform ultrasonic chemical plating treatment (frequency 20KHz, power 200W, temperature 70°C, reaction time 5min, adopt intermittent ultrasonic, filter and separate, and remove After washing with deionized water and washing with ethanol once, the silver-plated copper powder after washing is placed in a vacuum drying oven and dried.

[0059] Step (4) is: the silver-plated copper powder obtained in the step (3) is placed in the tube furnace, H 2 : N 2 =1:9 atmosphere, calcined at 200°C for 60 minutes, and the finished silver-plated all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com