Halogen-free flame-retardant epoxy resin composition and high-flexibility halogen-free cover film prepared from same

A technology of flame-retardant resin and epoxy resin, which is applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc., can solve the problems of high water absorption, poor flexibility of the covering film, and poor mechanical properties of the covering film. Achieve good softness, excellent softness, softness and better peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

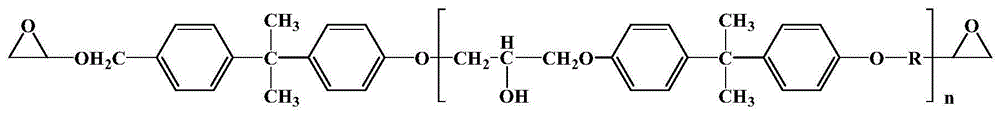

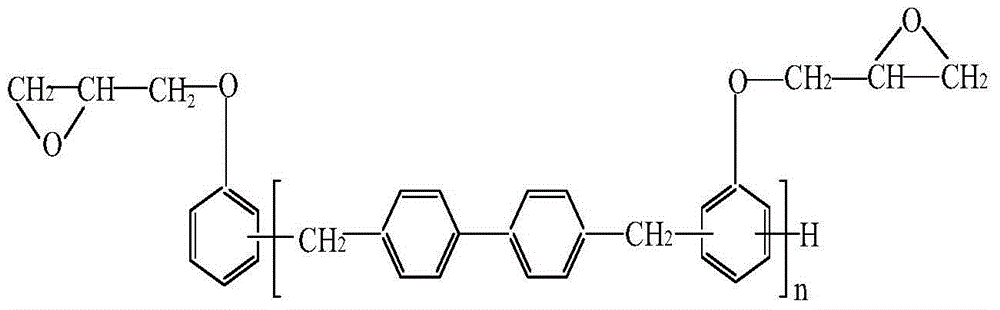

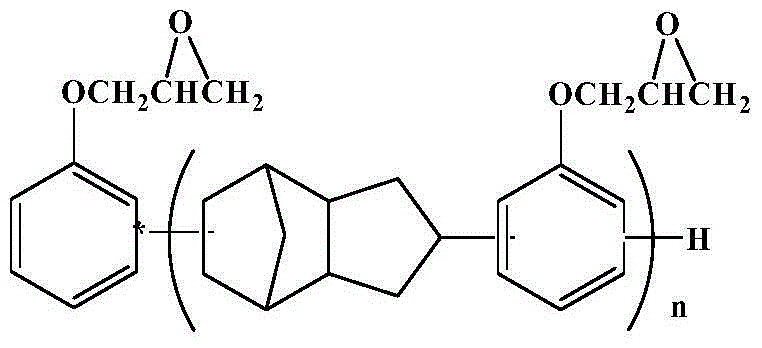

[0048] A halogen-free flame-retardant resin composition, including the following components by weight: flexible epoxy resin (product model DX7160, manufactured by Hunan Jiashengde Material Technology Co., Ltd.) 7.0 parts by weight; biphenyl epoxy resin (product model NC-3000, manufactured by Nippon Kayaku Co., Ltd.) 14.0 parts by weight; bisphenol A type epoxy resin (product model GESN901, manufactured by Hongchang Electronic Materials Co., Ltd.) 49.0 parts by weight; synthetic rubber (product model Nipol1072CG, acrylonitrile content 27 % by mass, manufactured by Zeon Corporation) 30.0 parts by weight; poly-1,4-butylene glycol bis(4-aminobenzoate) (product model ELASMER-1000P, manufactured by Ihara Chemical Industry Co., LTD.) 22.85 parts by weight; 5.36 parts by weight of 4,4'-diaminodiphenylsulfone; 0.5 parts by weight of 1-cyanoethyl-2-ethyl-4-methylimidazole (2E4MZ-CN); anti-aging agent (product model DNP, Quzhou City, Zhejiang Province) Jiang District Kaiyuan Fine Chemica...

Embodiment 2

[0051] A halogen-free flame-retardant resin composition, including the following components by weight: flexible epoxy resin (product model DX7160, manufactured by Hunan Jiashengde Material Technology Co., Ltd.) 14.0 parts by weight; biphenyl epoxy resin (product model NC-3000, manufactured by Nippon Kayaku Co., Ltd.) 14.0 parts by weight; bisphenol A type epoxy resin (product model GESN901, manufactured by Hongchang Electronic Materials Co., Ltd.) 42.0 parts by weight; synthetic rubber (product model Nipol1072CG, acrylonitrile content 27 % by mass, manufactured by Zeon Corporation) 30.0 parts by weight; poly-1,4-butylene glycol bis(4-aminobenzoate) (product model ELASMER-1000P, manufactured by Ihara Chemical Industry Co., LTD.) 15.42 parts by weight; 6.20 parts by weight of 4,4'-diaminodiphenylsulfone; 0.5 parts by weight of 1-cyanoethyl-2-ethyl-4-methylimidazole (2E4MZ-CN); anti-aging agent (product model DNP, Quzhou City, Zhejiang Province) Jiang District Kaiyuan Fine Chemic...

Embodiment 3

[0054] A halogen-free flame-retardant resin composition, including the following components by weight: flexible epoxy resin (product model DX7160, manufactured by Hunan Jiashengde Material Technology Co., Ltd.) 21.0 parts by weight; biphenyl epoxy resin (product model NC-3000, manufactured by Nippon Kayaku Co., Ltd.) 14.0 parts by weight; bisphenol A type epoxy resin (product model GESN901, manufactured by Hongchang Electronic Materials Co., Ltd.) 35.0 parts by weight; synthetic rubber (product model Nipol1072CG, acrylonitrile content 27 % by mass, manufactured by Zeon Corporation) 30.0 parts by weight; poly-1,4-butylene glycol bis(4-aminobenzoate) (product model ELASMER-1000P, manufactured by Ihara Chemical Industry Co., LTD.) 7.80 parts by weight; 7.05 parts by weight of 4,4'-diaminodiphenylsulfone; 0.5 parts by weight of 1-cyanoethyl-2-ethyl-4-methylimidazole (2E4MZ-CN); anti-aging agent (product model DNP, Quzhou City, Zhejiang Province) Jiang District Kaiyuan Fine Chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com