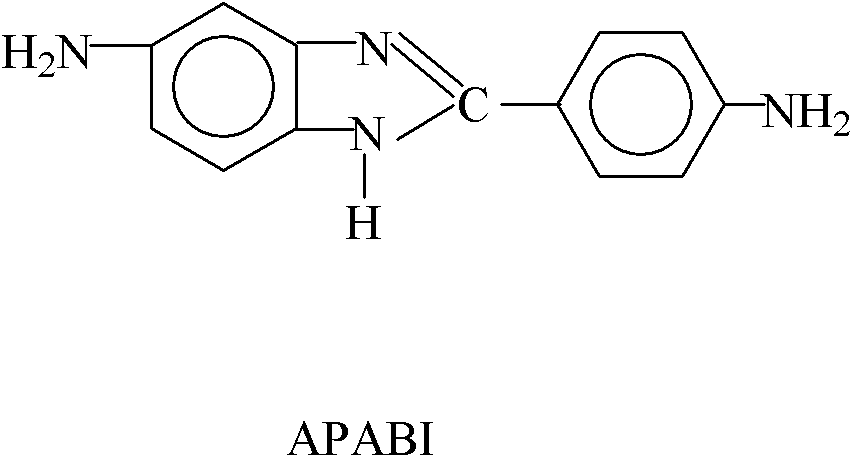

Benzimidazole diamine curing type epoxy adhesive and preparation method thereof

A technology of benzimidazole diamine and epoxy adhesive, which is applied in the direction of adhesive, epoxy resin glue, carboxyl rubber adhesive, etc., can solve the problems of high price, unfavorable large-scale promotion and application, high cost of polyetherimide resin, etc. problems, to achieve the effect of convenient operation, low cost, and industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 10.0 grams of carboxyl-terminated nitrile rubber (CTBN), 10.0 grams of bisphenol A epoxy resin (E-51), 30.0 grams of NOVOLIC novolac epoxy resin and 60.0 grams of N, N, N', N'-tetraglycidyl - Add the epoxy resin of 3,3'-dimethyl-4,4'-diaminodiphenylmethane into the reaction kettle, stir and react at 90°C for 0.5 hours, cool to 50°C, add 50.0 grams of hydrogenated bisphenol A epoxy resin and 50.0 grams of 3,4-epoxy cyclohexyl carboxylate-3', the reactive diluent of 4'-epoxy cyclohexyl methyl ester, stirred and reacted for 1 hour at 80°C to obtain 210.0 grams of homogeneous Transparent viscous liquid, denoted as B component;

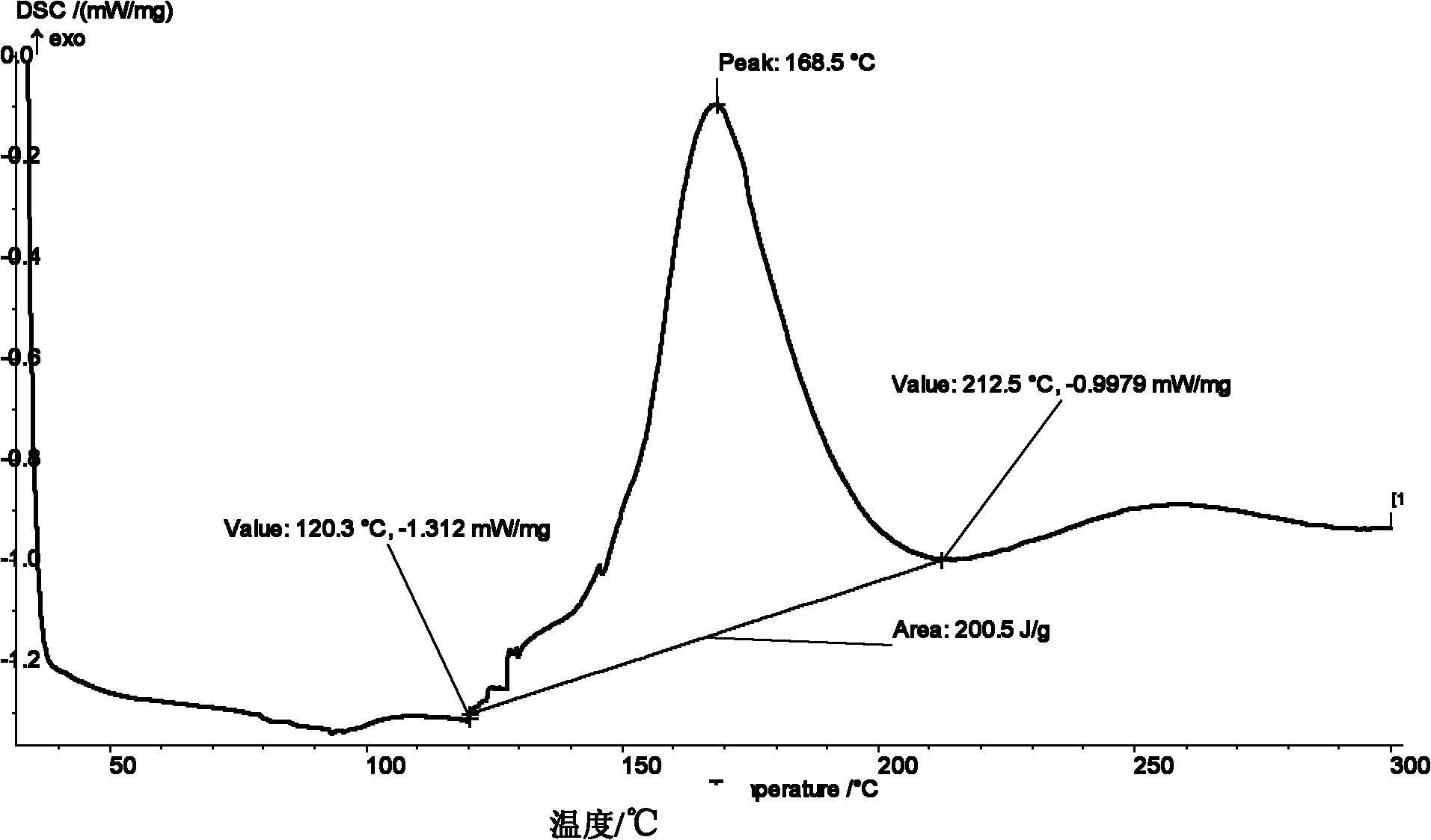

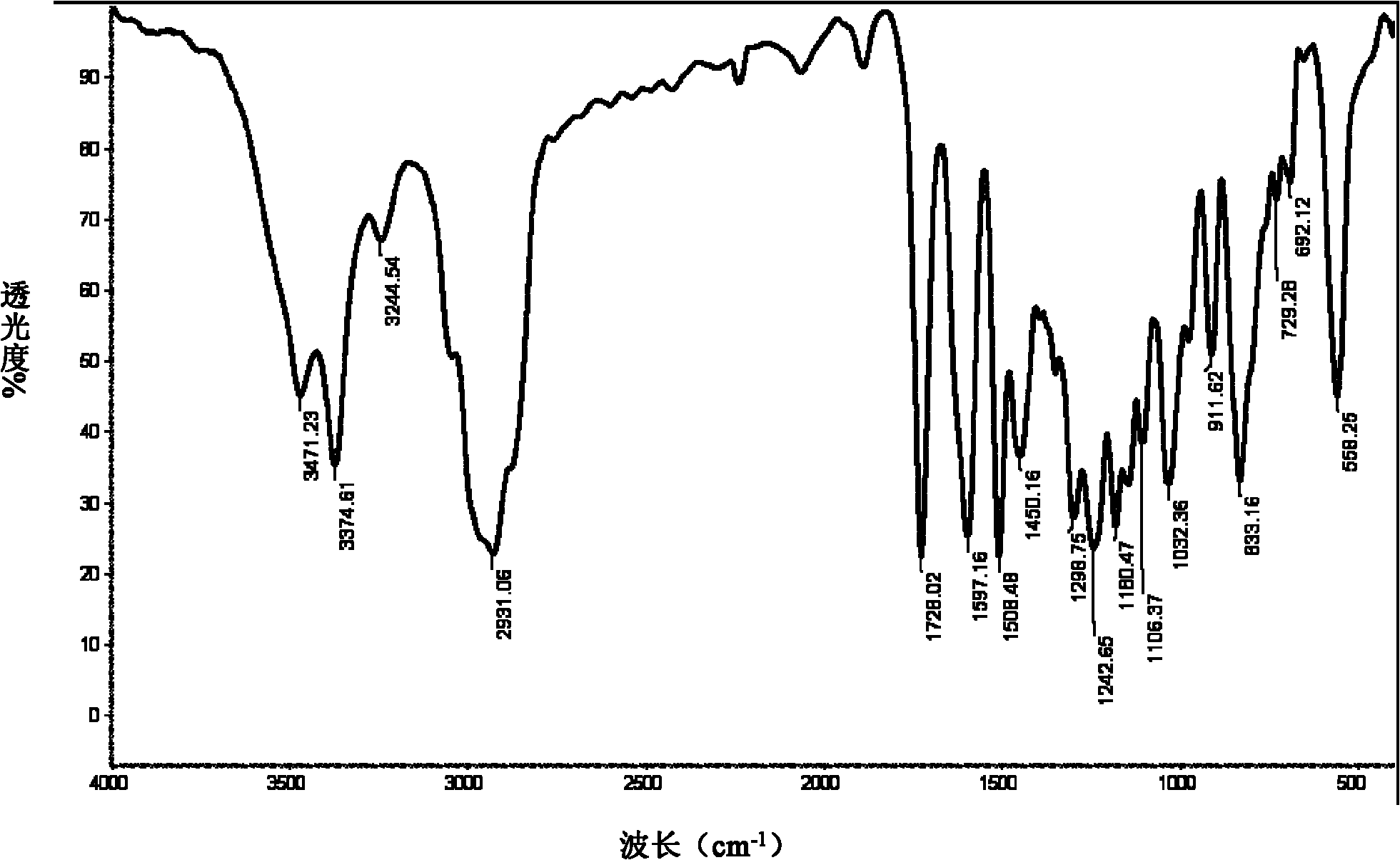

[0031] Mix 60.0 grams of the above B component with 3.0 grams of benzimidazole diamine (APABI) curing agent (A component), and stir evenly at room temperature to obtain the benzimidazole diamine curable epoxy adhesive, denoted as AEA-1 , its differential scanning calorimeter (DSC) scanning pattern (nitrogen atmosphere, heating rate 10 ℃ / min) as ...

Embodiment 2

[0035] 20.0 grams of carboxy-terminated nitrile rubber (CTBN), 100.0 grams of NOVOLIC novolac epoxy resin and 300.0 grams of N, N, N', N'-tetraglycidyl-4,4'-diaminodiphenylmethane epoxy Put the resin into the reactor, stir and react at 90°C for 0.5 hours, then cool to 50°C, add 500.0 grams of hydrogenated bisphenol A epoxy resin, 200.0 grams of resorcinol diglycidyl ether and 100.0 grams of 3,4-cyclo Oxygen-6-methyl-cyclohexanecarboxylic acid-3', 4'-epoxy-6-methyl-cyclohexyl methyl ester reactive diluent, stirred and reacted at 80°C for 1 hour to obtain 1220.0 g of homogeneous Transparent viscous liquid, denoted as B component;

[0036] Mix 60.0 grams of the above B component with 2.0 grams of benzimidazole diamine (APABI) curing agent (A component), and stir evenly at room temperature to obtain the benzimidazole diamine curable epoxy adhesive, denoted as AEA-2 .

[0037] Take an appropriate amount of the above-mentioned AEA-2 benzimidazole diamine curable epoxy adhesive, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com