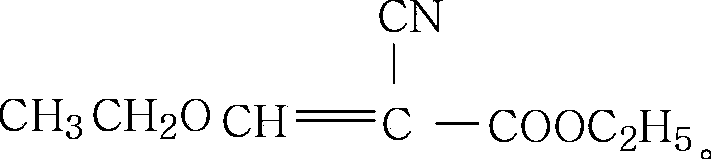

Alpha-cyanogroup-beta-ethyl ethoxyacrylate modified epoxy resin adhesive and preparation method thereof

A technology of ethoxylated ethyl acrylate and acrylic epoxy ester is applied in the field of epoxy resin adhesive and its preparation, and can solve the problems of high cost, high price, unfavorable large-scale popularization and application of polyetherimide resin, and the like. The effect of strong hydrophobicity, convenient operation and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Mix 50.0 g E-51 epoxy resin, 50.0 g TDE-85 epoxy resin, 30.0 g HPEI phenolic hydroxyl-containing polyetherimide and 30.0 g carboxyl-terminated nitrile rubber, stir and react at 60 °C for 20 min, add 80.0 grams of bisphenol A type epoxy acrylate resin, 20.0 grams of bisphenol A type epoxy methacrylate resin and 20.0 grams of α-cyano-β-ethoxyethyl acrylate, stir and mix well to obtain component A ;

[0032] Mix 65.0 grams of polyamide 650 resin, 10.0 grams of 3,3'-dimethyl-4,4'-diamino-dicyclohexylmethane and 5.0 grams of 2-ethyl-4-methylimidazole, and stir evenly, that is, is B component;

[0033] When in use, mix components A and B evenly to obtain an α-cyano-β-ethoxyethyl acrylate modified epoxy resin adhesive, which is denoted as EAN-1.

[0034]Take an appropriate amount of α-cyano-β-ethoxyethyl acrylate modified epoxy resin adhesive of EAN-1, and evenly coat it on the standard stainless steel test piece, superimpose, clamp, and put it in a blast oven for curing : ...

Embodiment 2

[0040] Mix 50.0 grams of E-51 epoxy resin, 50.0 grams of E-44 epoxy resin with 15.0 grams of amino-terminated nitrile rubber and 15.0 grams of carboxyl-terminated nitrile rubber, and after stirring and reacting at 80 °C for 15 minutes, add 50.0 grams of bisphenol A type acrylic epoxy ester resin and 5.0 g of α-cyano-β-ethoxyethyl acrylate, stir and mix evenly to obtain component A;

[0041] Mix 5.0 g of polyamide 650 resin, 2.0 g of methyltetrahydrophthalic anhydride, 8.0 g of 3,3'-dimethyl-4,4'-diamino-dicyclohexylmethane and 15.0 g of DMP-30, stir well, is the B component;

[0042] When in use, mix components A and B evenly to obtain an α-cyano-β-ethoxyethyl acrylate modified epoxy resin adhesive, which is denoted as EAN-2.

[0043] Take an appropriate amount of α-cyano-β-ethoxyethyl acrylate modified epoxy resin adhesive of EAN-2, and evenly coat it on the standard stainless steel test piece, stack it, clamp it, and put it in a blast oven for curing : Begin to heat up to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com