Frame sealing adhesive, and preparation method and application thereof

A technology of sealing glue and rubber powder, applied in chemical instruments and methods, adhesives, printing plate preparation, etc., can solve problems such as product storage and transportation troubles, lack of bonding performance, etc., achieve high dimensional stability, and do not pollute liquid crystals Performance, effect of low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

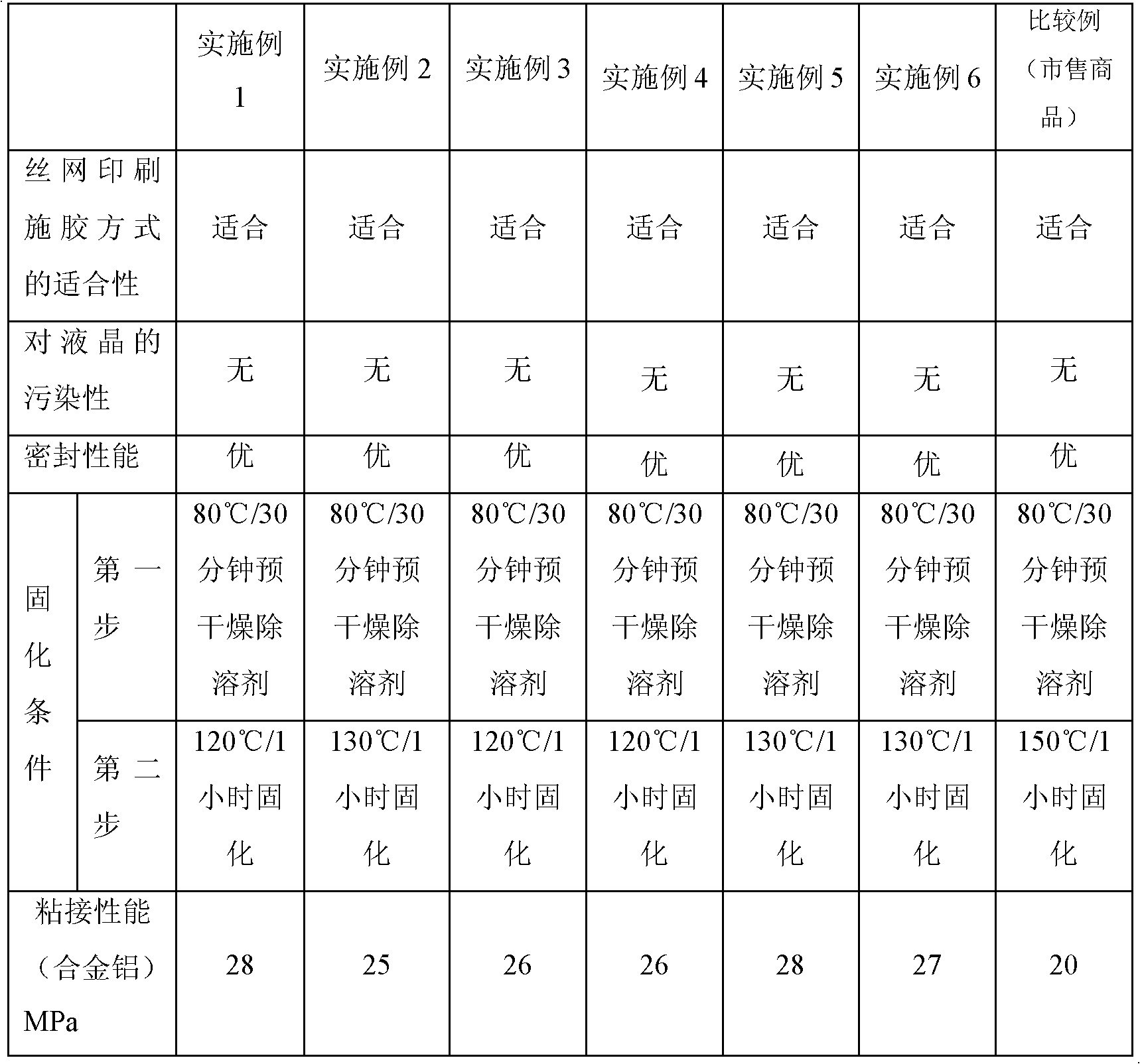

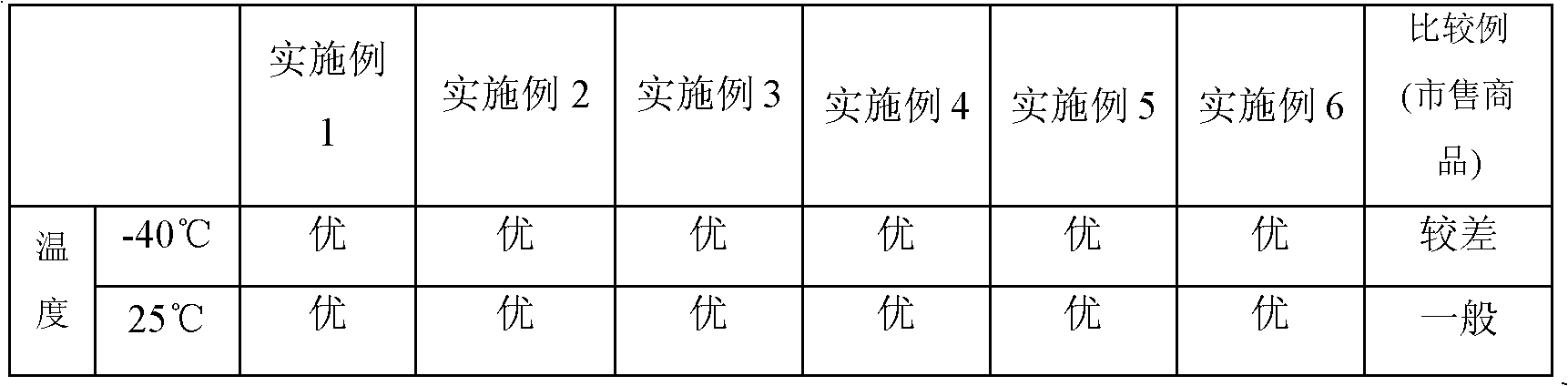

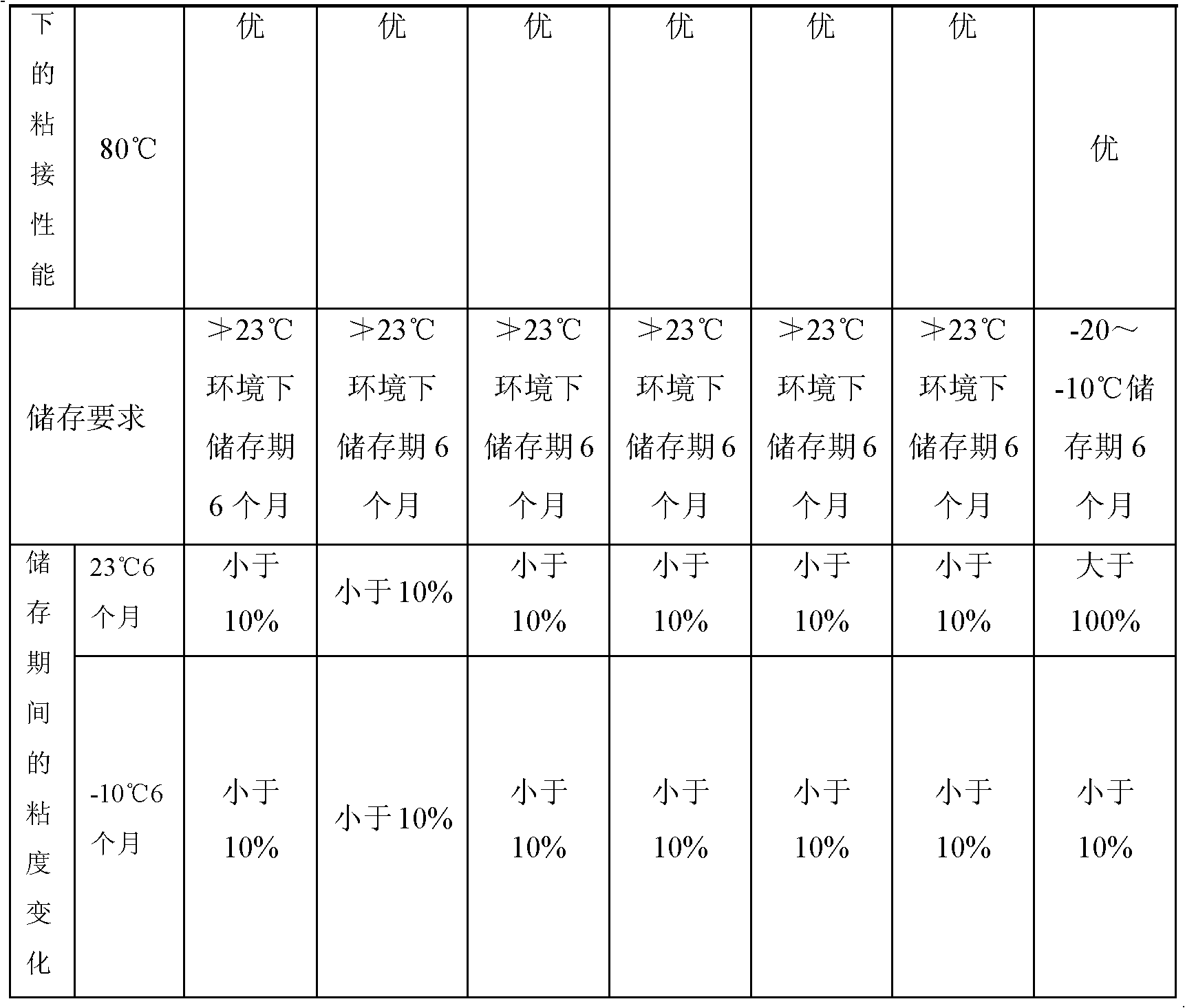

Examples

Embodiment 1

[0022] Utilize planetary stirring equipment to make the following components: bisphenol A epoxy resin NPEL-134 (purchased from Nanya Epoxy Resin (Kunshan) Co., Ltd., hydrolyzed chlorine content is less than 300 × 10 -6 mg / kg) 68 parts by weight, curing agent adipic acid dihydrazide (purchased from Wuxi Liangxi Fine Chemical Co., Ltd.) 8 parts by weight (use jet mill ultra-fine grinding equipment to process, the average particle size after processing is 3 μm, The maximum particle size is 5 microns), VP501 carboxylated nitrile rubber for ultrafine fully vulcanized powder rubber (particle size is 50-200nm, purchased from Beijing Research Institute of Chemical Industry) 5 parts by weight, filler silica CL-2008-III (purchased from Hebei Xinhao Nano Material Co., Ltd., the average particle size is 1 μm, the maximum particle size is less than 5 μm) 7 parts by weight, thixotropic agent fumed silica Degussa A200 type 1 part by weight, silane coupling agent KH560 (purchased from Nanjing...

Embodiment 2

[0025] Following the same method as in Example 1, only the curing agent was replaced by isophthalic acid dihydrazide (purchased from Jinan Leqi Chemical Co., Ltd.), to obtain a frame sealant.

[0026] The maximum particle diameter of the sealant prepared in this example is less than 5 microns, has good storage performance, is suitable for screen printing sizing, and can be cured (pre-dried at 80°C for 30 minutes to remove solvent and then kept at 130°C for 60 minutes) It will be cured after 10 minutes) and then used for the frame sealing of TN (STN) liquid crystal cell.

Embodiment 3

[0028] Following the same method as in Example 1, only the rubber powder was replaced with VP301 acrylate rubber (with a particle size of 50-200 nm, Beijing Research Institute of Chemical Industry) to obtain a frame sealant.

[0029] The largest particle diameter of the sealant prepared in this example is less than 5 microns, has good storage performance, is suitable for screen printing sizing, and can be cured (pre-dried at 80°C for 30 minutes to remove solvent and then kept at 120°C for 60 minutes). It will be cured after 10 minutes) and then used for the frame sealing of TN (STN) liquid crystal cell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com