Method for preparing flexible heat conducting insulating adhesive film used in LED heat radiation substrate

A technology of heat conduction, insulation and high heat conduction, which is applied in the direction of carboxyl rubber adhesives, chemical instruments and methods, adhesives, etc., which can solve the problems of complex preparation process and achieve high peel strength, strong adhesion, and strong flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

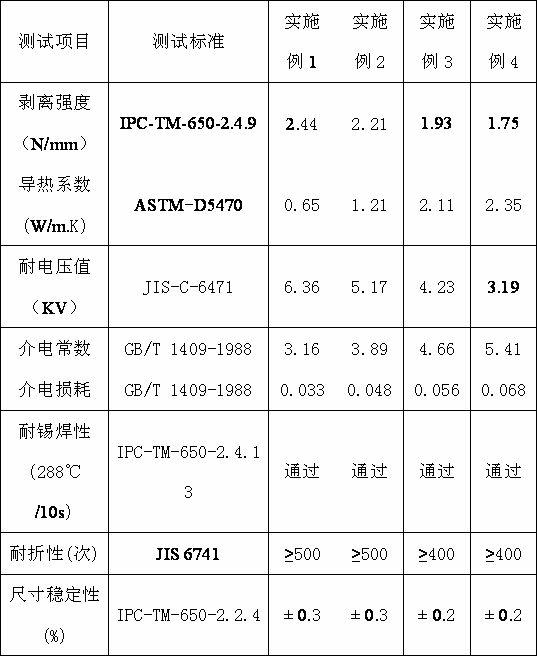

Examples

Embodiment 1

[0034] Place the high thermal conductivity inorganic filler in a vacuum oven at 140°C to vacuum dry for 4 hours to remove moisture, and cool to room temperature; weigh the high thermal conductivity inorganic filler in an ethanol aqueous solution (95% by volume of ethanol) in which the coupling agent KH560 is dissolved according to the proportion %), heated in a water bath to 40°C, stirred for 4 hours, filtered, washed twice with absolute ethanol, dried in vacuum at 60°C for 12 hours, ground into powder to obtain a surface-treated high thermal conductivity inorganic filler for use;

[0035] Choose bisphenol A epoxy resin E-44 as liquid epoxy resin, choose bisphenol A epoxy resin CYD-014 as solid epoxy resin, choose CTBN1300×31 as toughening agent, choose dapsone as curing agent , the mixture of alumina, boron nitride and silicon carbide (arbitrary ratio) is selected as the high thermal conductivity inorganic filler, H-1331 is selected as the leveling agent, and the mixed solutio...

Embodiment 2

[0039] The surface treatment process of the high thermal conductivity inorganic filler is as described in Example 1, and the coupling agent is replaced by KH550.

[0040] Choose bisphenol A epoxy resin E-42 as liquid epoxy resin, choose bisphenol A epoxy resin CYD-011 as solid epoxy resin, choose carboxyl-terminated liquid nitrile rubber CTBN1300×8 as toughener, choose Dapsone is used as a curing agent, a mixture of alumina, boron nitride and silicon carbide (arbitrary ratio) is used as a high thermal conductivity inorganic filler, H-140 is used as a leveling agent, ethyl acetate, tetrahydrofuran and dimethylformamide are selected (arbitrary ratio) of the mixed solution as an organic solvent. The preparation process of the thermally conductive and insulating adhesive is as described in Example 1, and the dosage of each formulation of the flexible thermally conductive and insulating adhesive is shown in Example 2 in Table 1.

[0041] The obtained flexible thermally conductive ...

Embodiment 3

[0044] The surface treatment process of the high thermal conductivity inorganic filler is as described in Example 1, and the coupling agent is replaced by TMC-201.

[0045] The polybutadiene epoxy resin Oxiron 2000 was selected as the liquid epoxy resin, the o-cresol novolac epoxy resin CYDCN-100 was selected as the solid epoxy resin, the amino-terminated liquid nitrile rubber ATBN1300×35 was selected as the toughening agent, and aminobenzene was selected Sulfone is used as curing agent, the mixture of alumina, boron nitride and silicon carbide (arbitrary ratio) is used as high thermal conductivity inorganic filler, H-1231 is used as leveling agent, acetone, tetrahydrofuran and dimethylformamide (arbitrary ratio) are selected mixed solution as an organic solvent. The preparation process of the flexible thermally conductive insulating adhesive is as described in Example 1, and the dosage of each formulation of the flexible thermally conductive insulating adhesive is shown in Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com