Light curing adhesive for splicing capacitive touch screen and preparation method of light curing adhesive

A capacitive touch screen, light-curing technology, applied in the direction of adhesives, carboxyl rubber adhesives, adhesive types, etc., can solve the problems of low curing shrinkage, yellowing resistance, low refractive index, etc., and achieve low curing shrinkage High efficiency, good yellowing resistance, high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

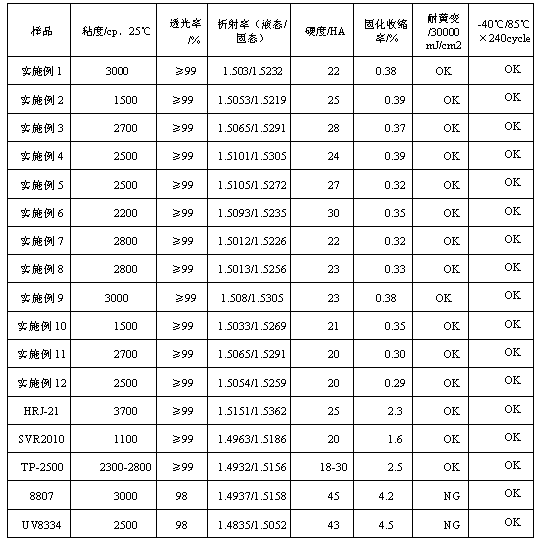

Examples

preparation example Construction

[0056] The present invention proposes a preparation method for preparing the above-mentioned photocurable adhesive for capacitive touch screen bonding, which comprises the following steps:

[0057] Step 1: According to weight percentage, take 30%-50% of main resin, 20%-40% of auxiliary resin, 10%-30% of active monomer, 0.5%-5% of photoinitiator, and 0.1%-5% of auxiliary agent;

[0058] Step 2: Stir well and serve.

Embodiment 1

[0061] Take the following components,

[0062] Main resin: 30g high molecular weight aliphatic urethane acrylate resin with grade CN980,

[0063] Auxiliary resin: 40g brand is the acrylate-modified isocyanuric acid resin of UV1820,

[0064] Active monomer: 25g of isobornyl acrylate (IBOA) of SR506 produced by Sartomer Company,

[0065] Photoinitiator: 4.0 g of 1-hydroxyl-cyclohexyl benzophenone of I-184,

[0066] Auxiliary agent: 0.5g of coupling agent, choose γ-methacryloxypropyl trimethoxysilane with brand A-174, and 0.5g of leveling agent, choose polyacrylic acid with brand TEGO-370 ester solution.

[0067] The above-mentioned components are stirred evenly.

[0068] After conversion, the main resin accounts for 30.0%, the auxiliary resin accounts for 40.0%, the active monomer accounts for 25%, the photoinitiator accounts for 4.0%, and the auxiliary agent accounts for 1.0%.

[0069]

Embodiment 2

[0071] Take the following components,

[0072] Main resin: 49.9g high molecular weight aliphatic urethane acrylate resin with grade CN964,

[0073] Auxiliary resin: 35g vinyl-terminated liquid nitrile rubber of the grade VTBN1300X33,

[0074] Active monomer: 10g hydroxyethyl methacrylate (HEMA, selected from Guangzhou Sanwang Chemical Materials Co., Ltd.),

[0075] Photoinitiator: 5.0g brand is the macromolecule photoinitiator of the oligomeric polyfunctional group-a-hydroxy ketone of ESACURE ONE,

[0076] Auxiliary agent: 0.05g coupling agent, γ-aminopropyltriethoxysilane with brand A-1100, and 0.05g leveling agent, polyacrylate solution with brand TEGO-460.

[0077] The above-mentioned components are stirred evenly.

[0078] After conversion, the main resin accounts for 49.9%, the auxiliary resin accounts for 35.0%, the active monomer accounts for 10.0%, the photoinitiator accounts for 5.0%, and the auxiliary agent accounts for 0.1%.

[0079]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com