Bio-based epoxy resin composition and application thereof in preparing epoxy resin film

A technology based on epoxy resin and epoxy resin glue, applied in the direction of epoxy resin glue, silicon organic compound, carboxyl rubber adhesive, etc., can solve the problem of high hydrolyzable chlorine content, low yield, and more waste liquid. problems, to achieve the effects of improving processing fluidity, improving dielectric properties, and reducing system viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

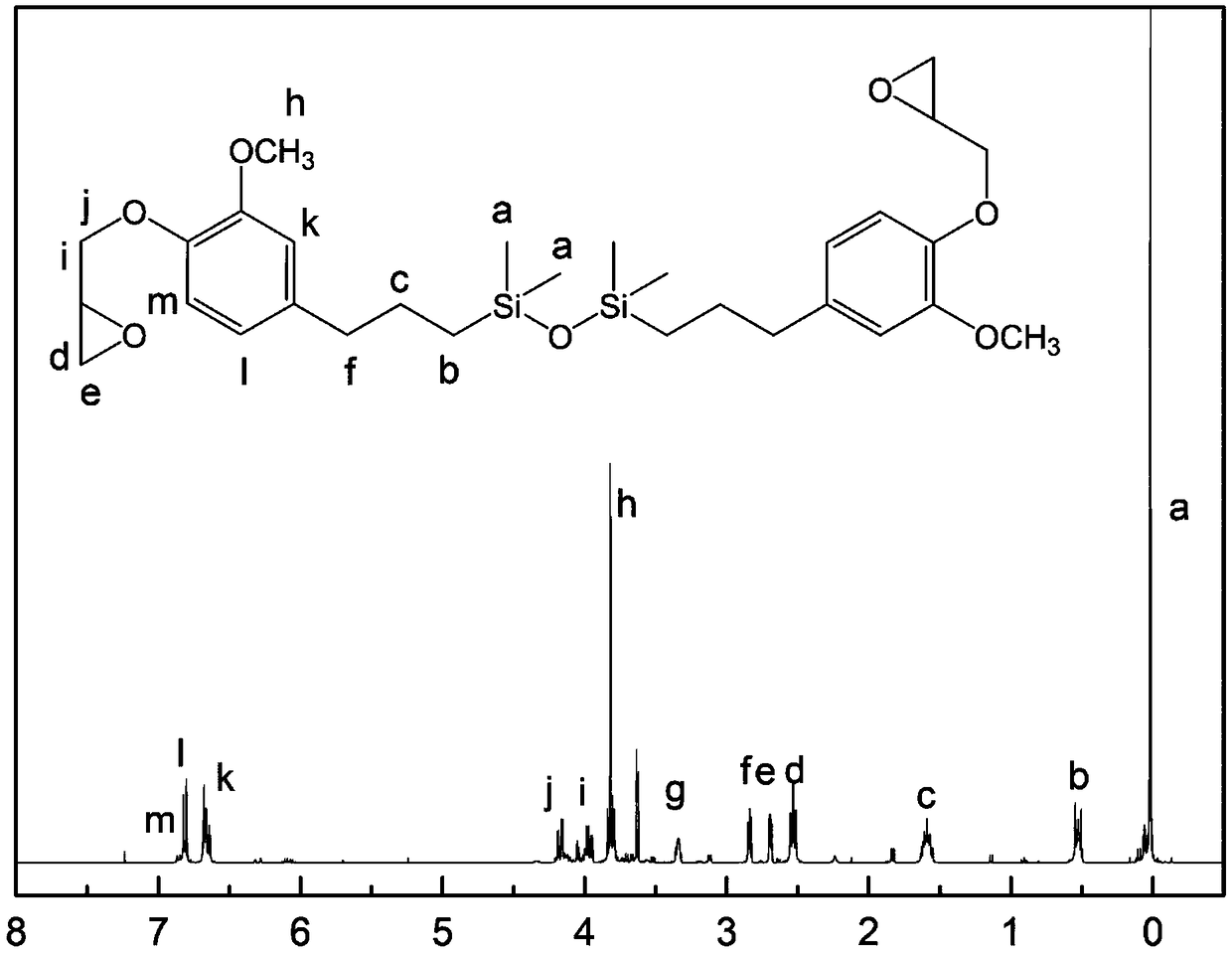

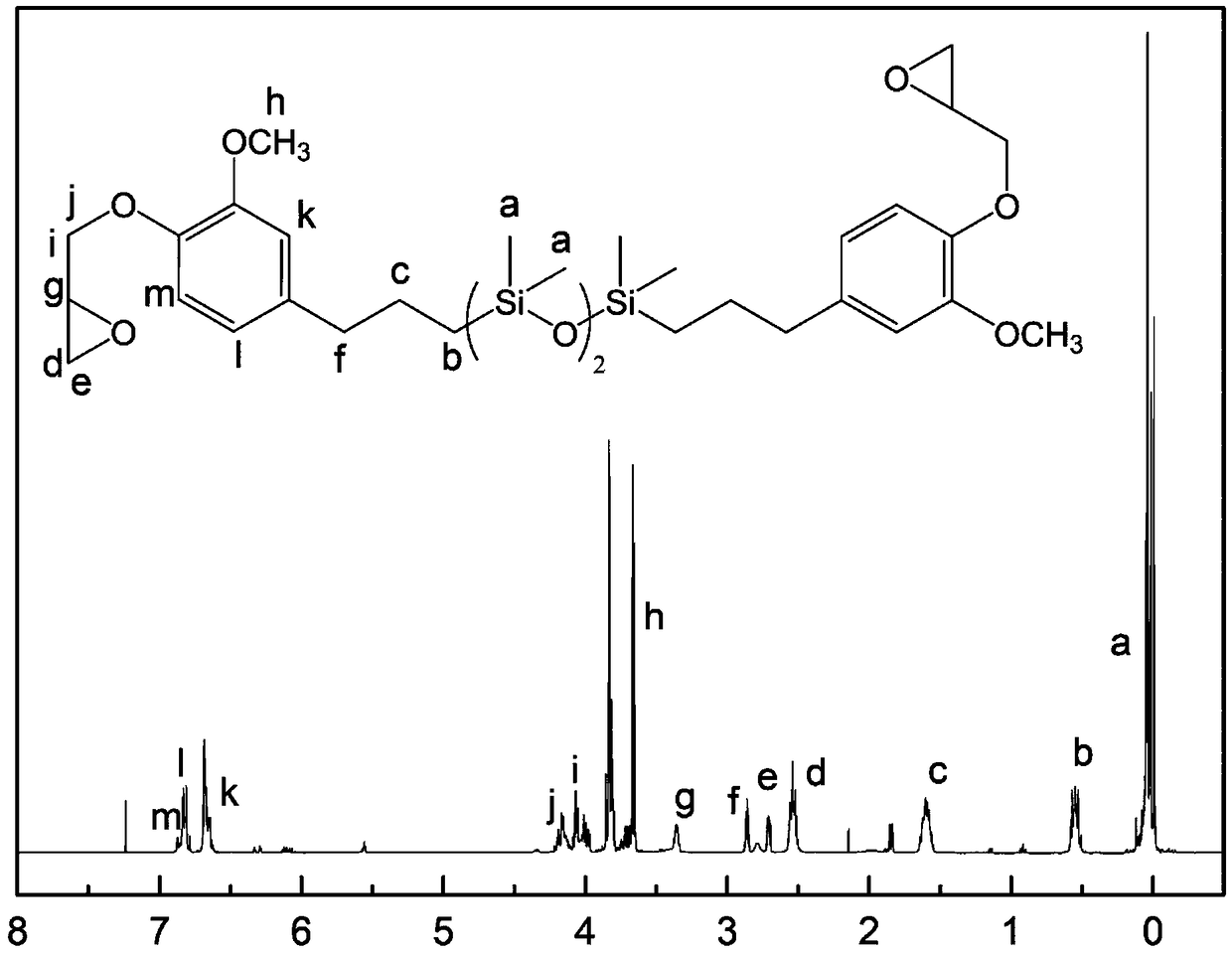

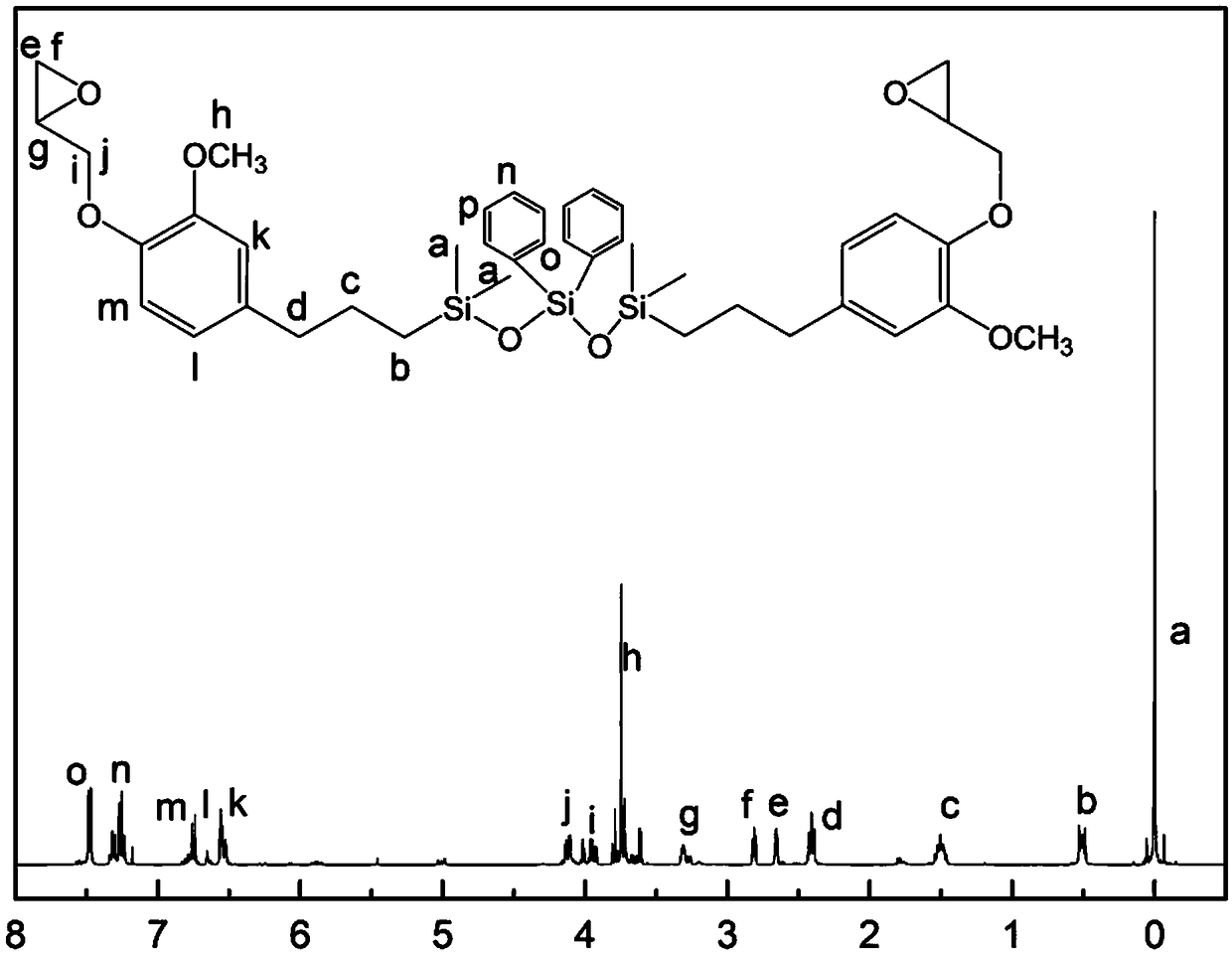

Image

Examples

Embodiment 1

[0077] Benzyltriethylammonium chloride aqueous solution (concentration: 20g / L, 100mL) was mixed with halloysite nanotubes (5g), and the water was removed by evaporation, and the remaining substance was heated in an ultrasonic microwave device at 120°C for 20min. The halloysite nanotube catalyst immobilized with benzyltriethylammonium chloride is obtained.

[0078] Under normal pressure, eugenol and epichlorohydrin (molar ratio 1:1) were added, and the halloysite nanotubes immobilized with benzyltriethylammonium chloride prepared in this example were added in proportion as catalyst (benzyltriethylammonium chloride). The molar ratio of ethylammonium chloride to eugenol=0.05:1), etherification ring-opening reaction was carried out at 100°C, and the reaction time was 2 hours to obtain chlorohydrin ether; when the system was cooled to about 60°C, add Sodium hydroxide (the molar ratio of sodium hydroxide to eugenol = 1.05:1), was added in batches within 3 hours, and the heat preserv...

Embodiment 2

[0084] Take 100phr of bio-based epoxy resin prepared in Example 1, 20phr of dicyandiamide, 0.3phr of 2-methylimidazole, and 25phr of nitrile rubber, and use a ball mill to mix them uniformly and then apply them on the polyester grid cloth carrier by a coating machine , with a thickness of 150 μm, placed in a 150°C oven and heated for 5 minutes to form a partially pre-cured composition adhesive layer, and then rolled it with release paper to form an adhesive film. The performance test results of the epoxy resin film are listed in Table 1 below.

Embodiment 3

[0086] Benzyltriethylammonium chloride aqueous solution (concentration: 1000g / L, 50mL) was mixed with halloysite nanotubes (10g), and the water was removed by evaporation, and the remaining substance was heated in an ultrasonic microwave device at 150°C for 40min. The halloysite nanotube catalyst immobilized with benzyltriethylammonium chloride is obtained.

[0087] Under normal pressure, eugenol and epichlorohydrin (molar ratio 1:1) were added, and the halloysite nanotubes immobilized with benzyltriethylammonium chloride prepared in this example were added in proportion as a catalyst (benzyltriethylammonium chloride). The molar ratio of triethylammonium chloride to eugenol=0.05:1), etherification ring-opening reaction was carried out at 110°C, and the reaction time was 2 hours to obtain chlorohydrin ether; Add sodium hydroxide (the molar ratio of sodium hydroxide to eugenol = 1.05:1), add in batches within 3 hours, and keep warm for 4 hours; put the system to stand, cool and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com