Patents

Literature

34results about How to "With flame retardant properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of polymer composite gelling agent for grouting and application method thereof

The invention belongs to the technical field of a gelling agent for geologic hazard control as well as filling control of goaf and waste laneway or collapse craters after exploitation of other mines, and provides a formula and a method of a novel polymer composite gelling agent for grouting. The gelling agent comprises the following components in percentage by weight: 10-25% of bentonite, 5-20% of cellulose, 5-20% of vegetable gum, 10-15% of calcium hydroxide, 10-25% of inorganic hygroscopic agent, 0.5-1.5% of inorganic dispersant, 0.5-2% of inorganic flocculent, 6-18% of organic flocculent, and 5-15% of alkali metal carbonate. The gelling agent is used for processing and crushing, mixing with water, and injecting to slurry for gelling. According to the invention, the characteristics of high-hydroscopicity mineral matters and hydroscopic synthetic resin are sufficiently absorbed and utilized, and various ion groups are introduced and adjusted to obtain specific performance, so that the gelling agent has strong water solubility, can form hydrophile and water-insoluble gel in the slurry, and has excellent adhesion force to solids and dissolved matters in the slurry, good gelling property, strong water control function, high and adjustable jelling speed, low cost and no pollution.

Owner:JICHANG XIANDAO ENG MATERIAL

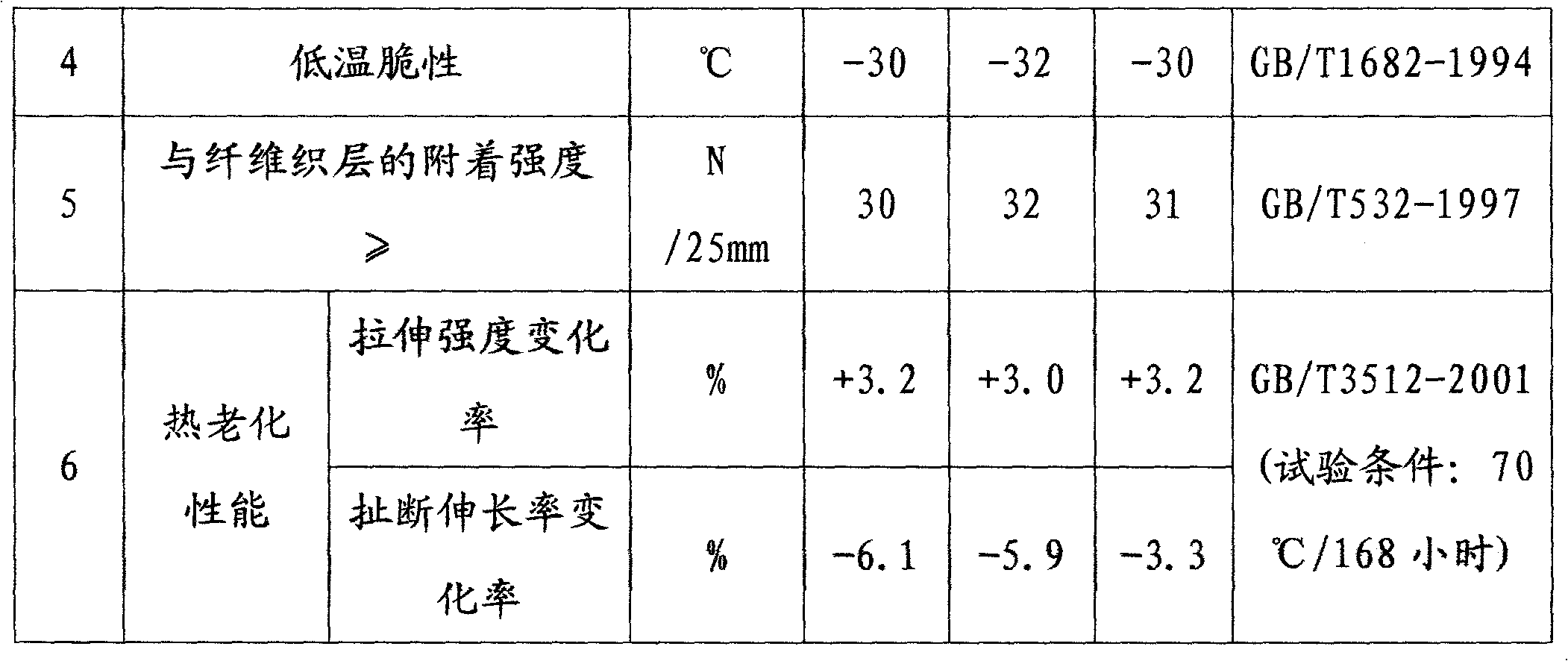

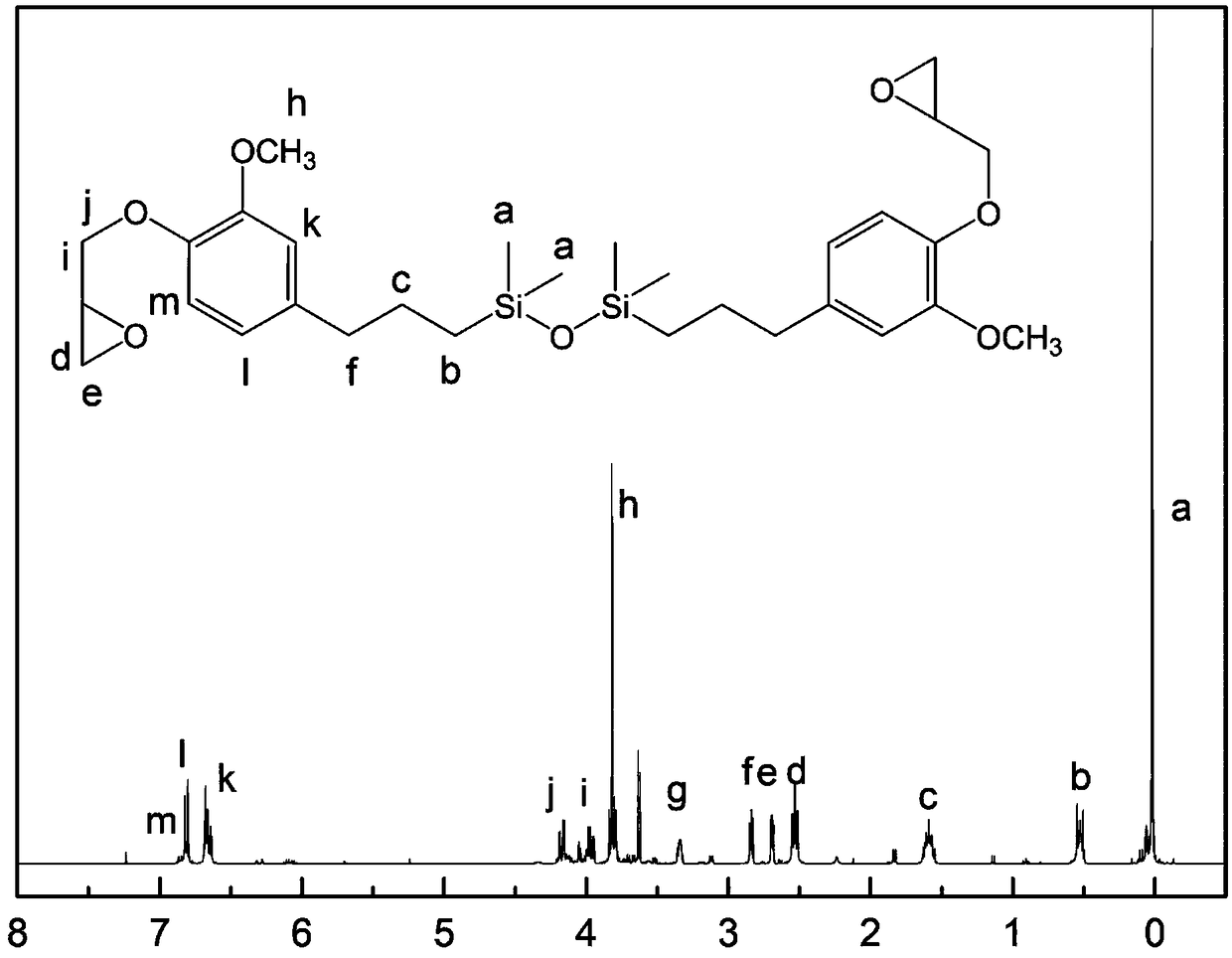

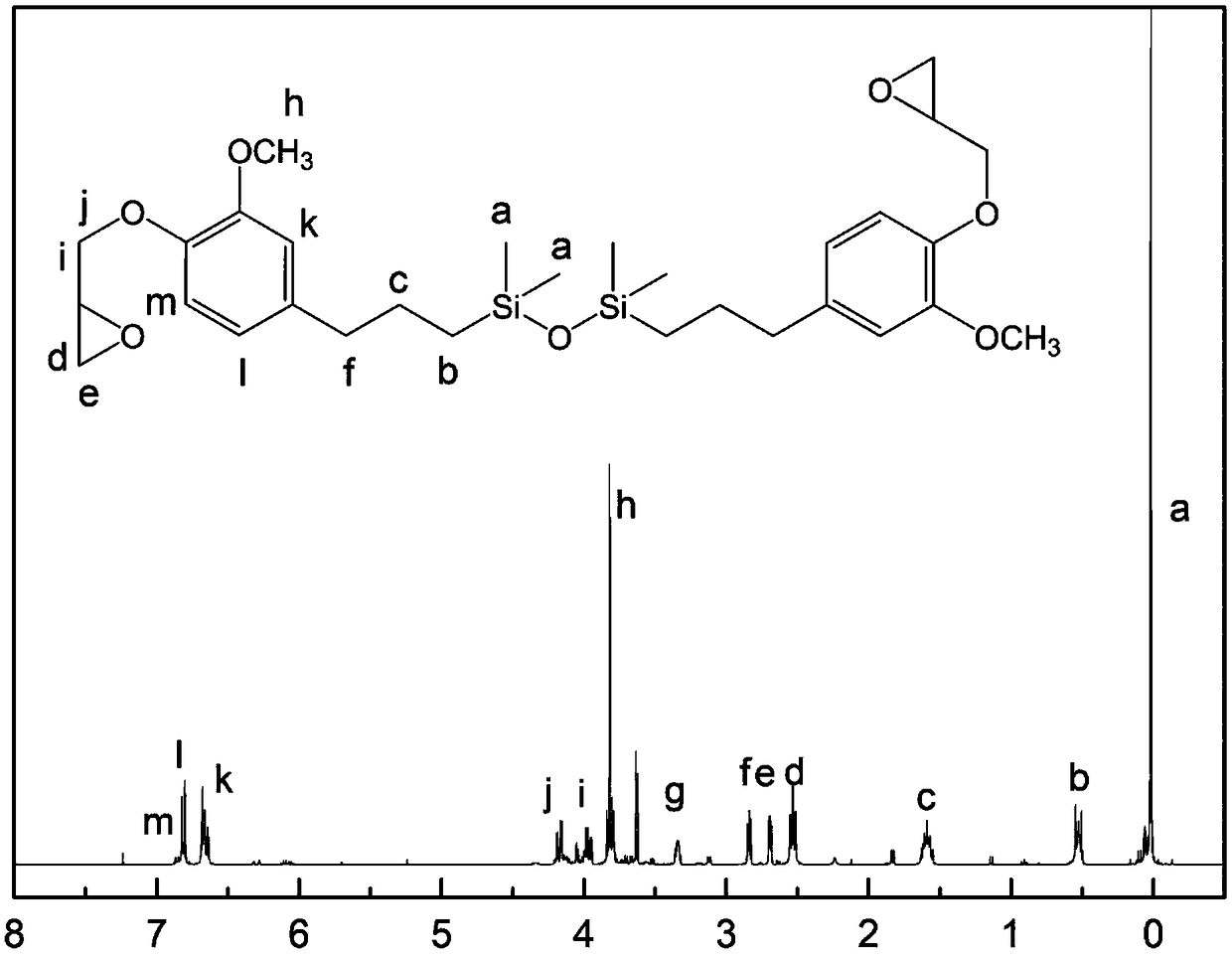

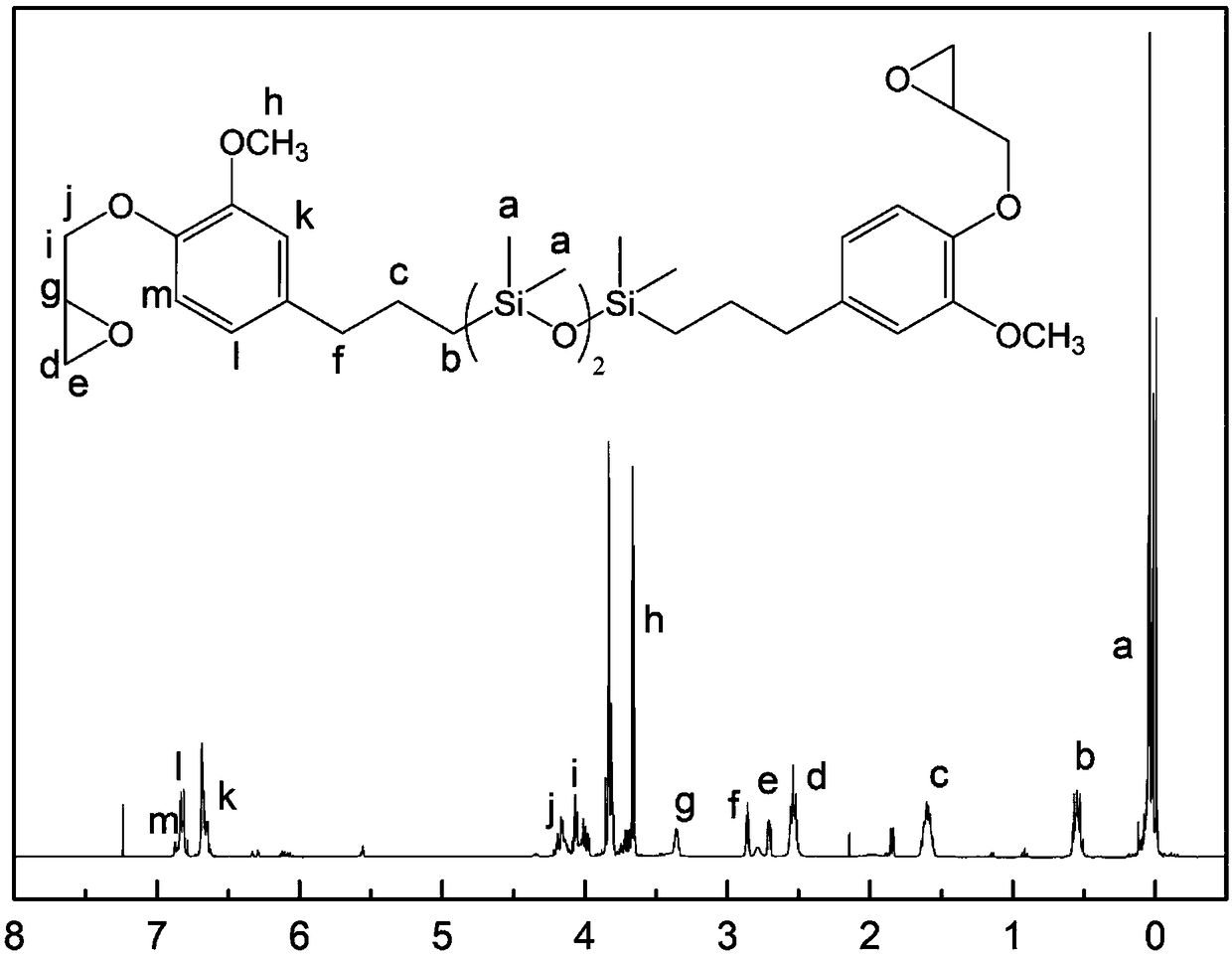

Bio-based epoxy resin composition and application thereof in preparing epoxy resin film

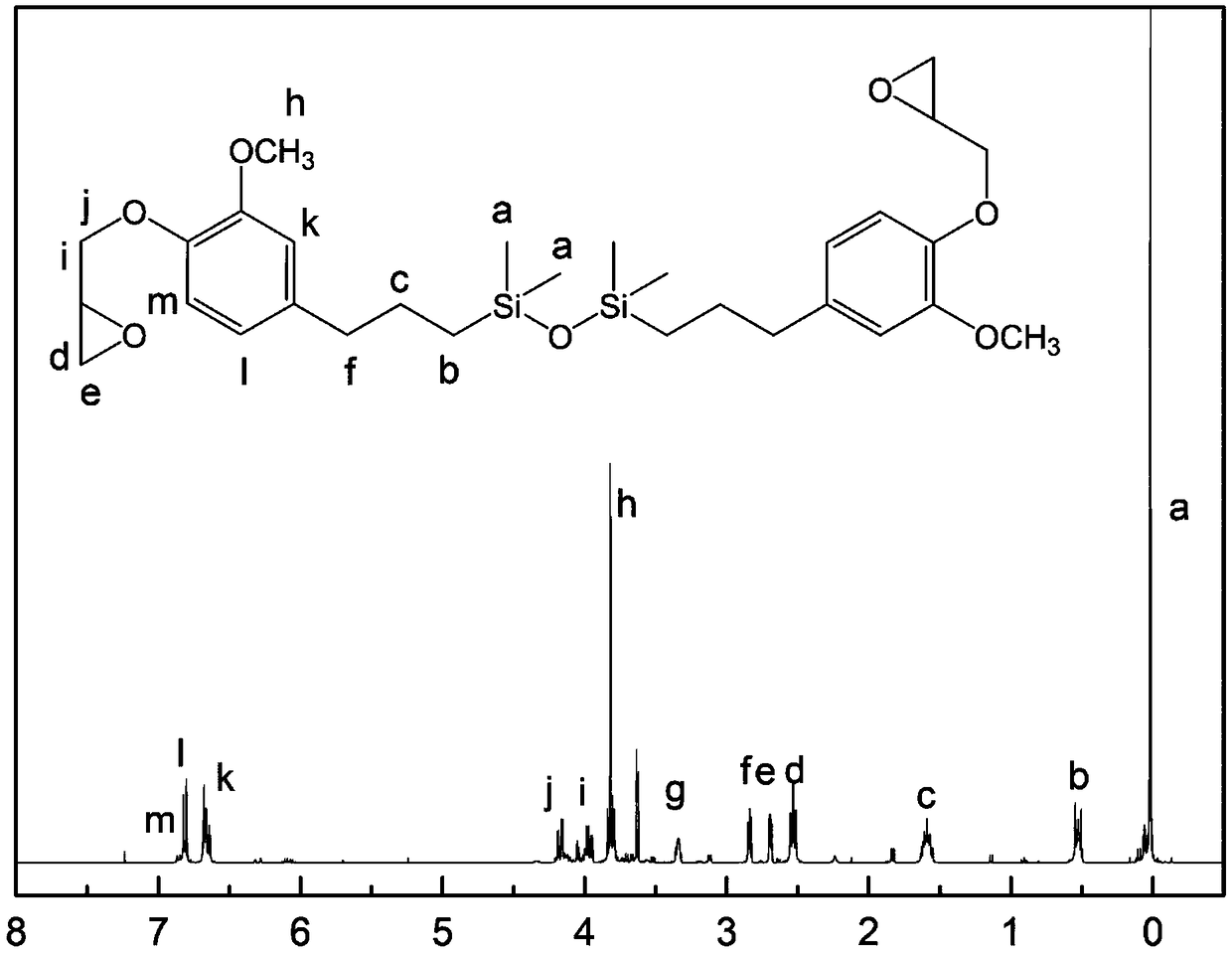

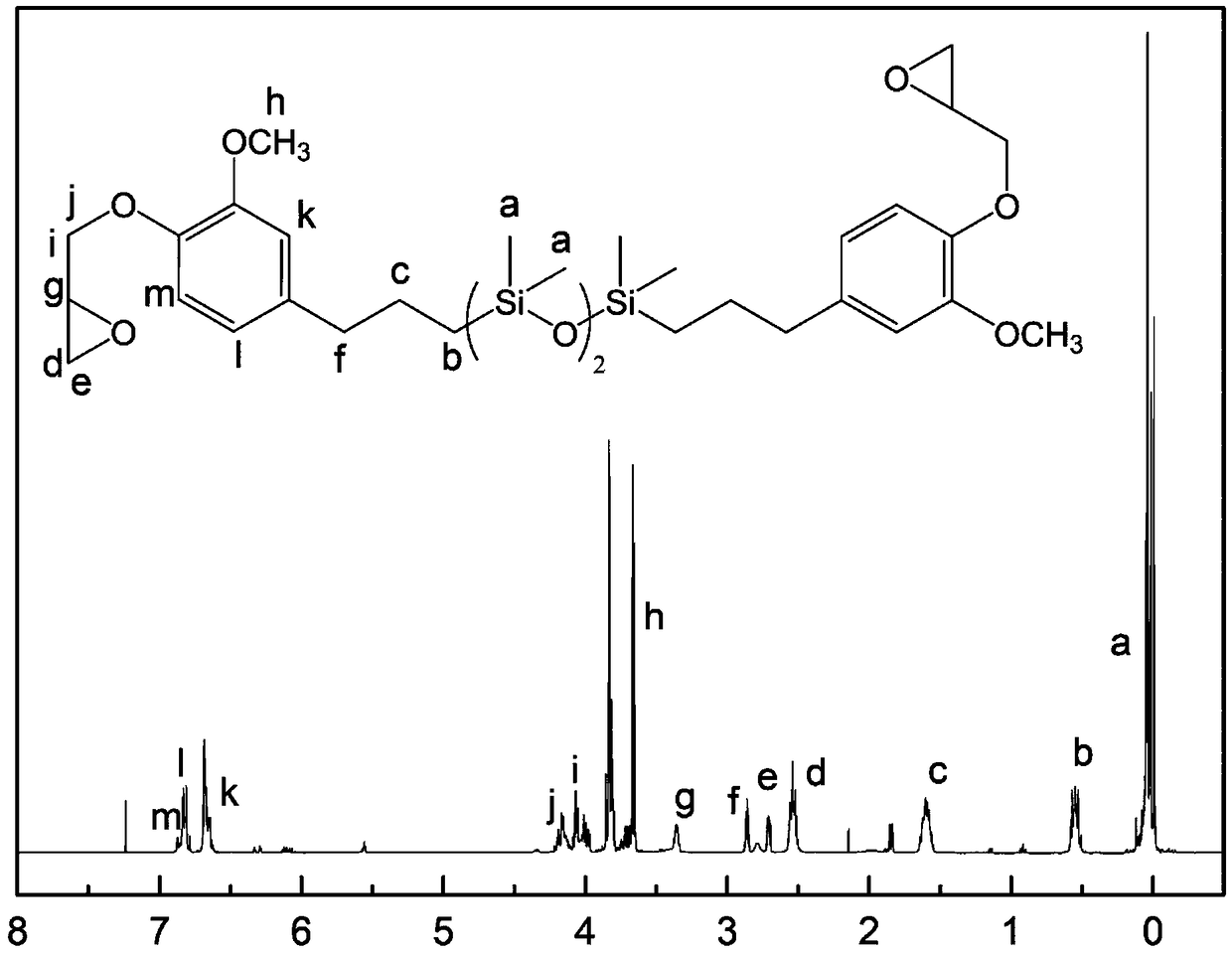

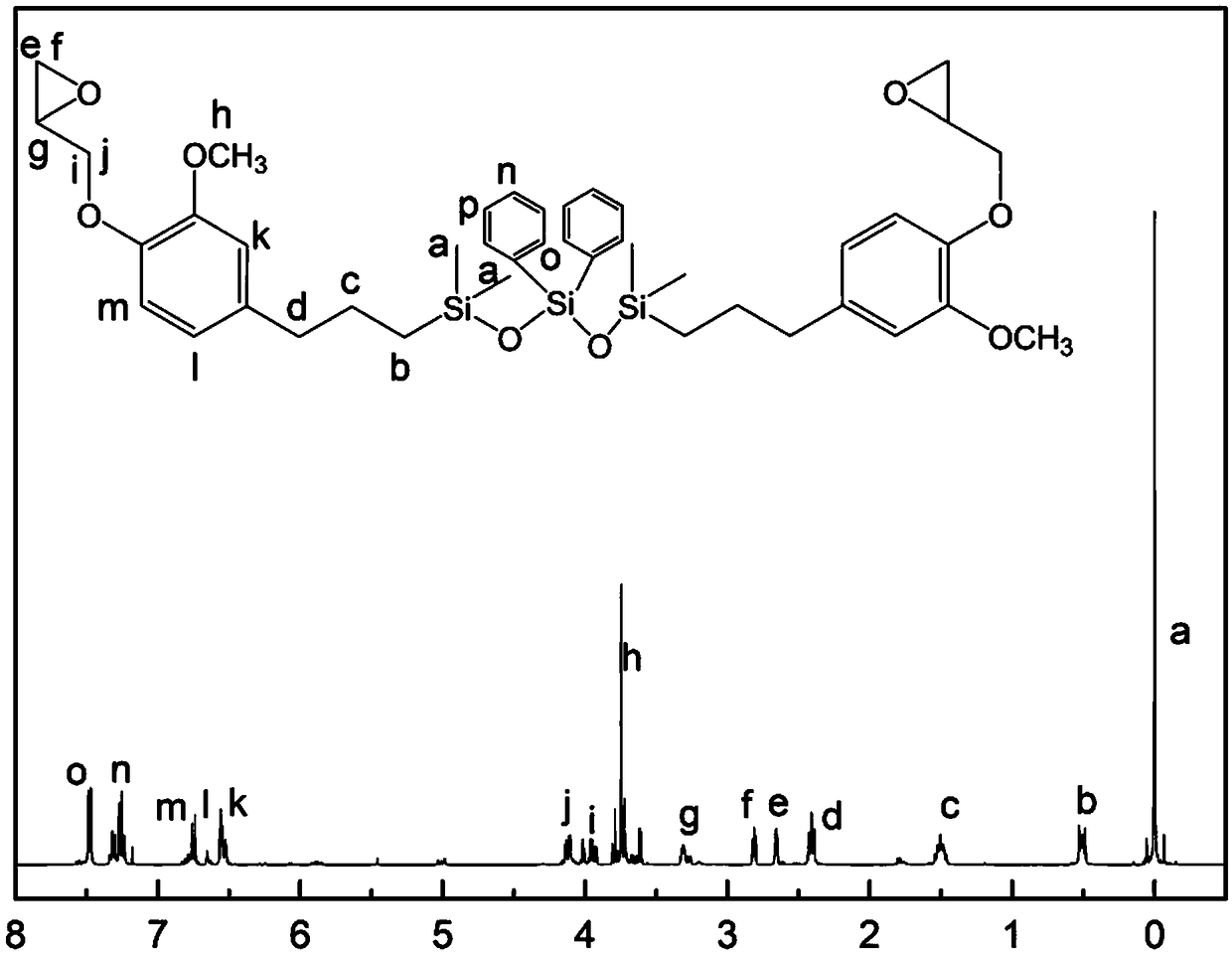

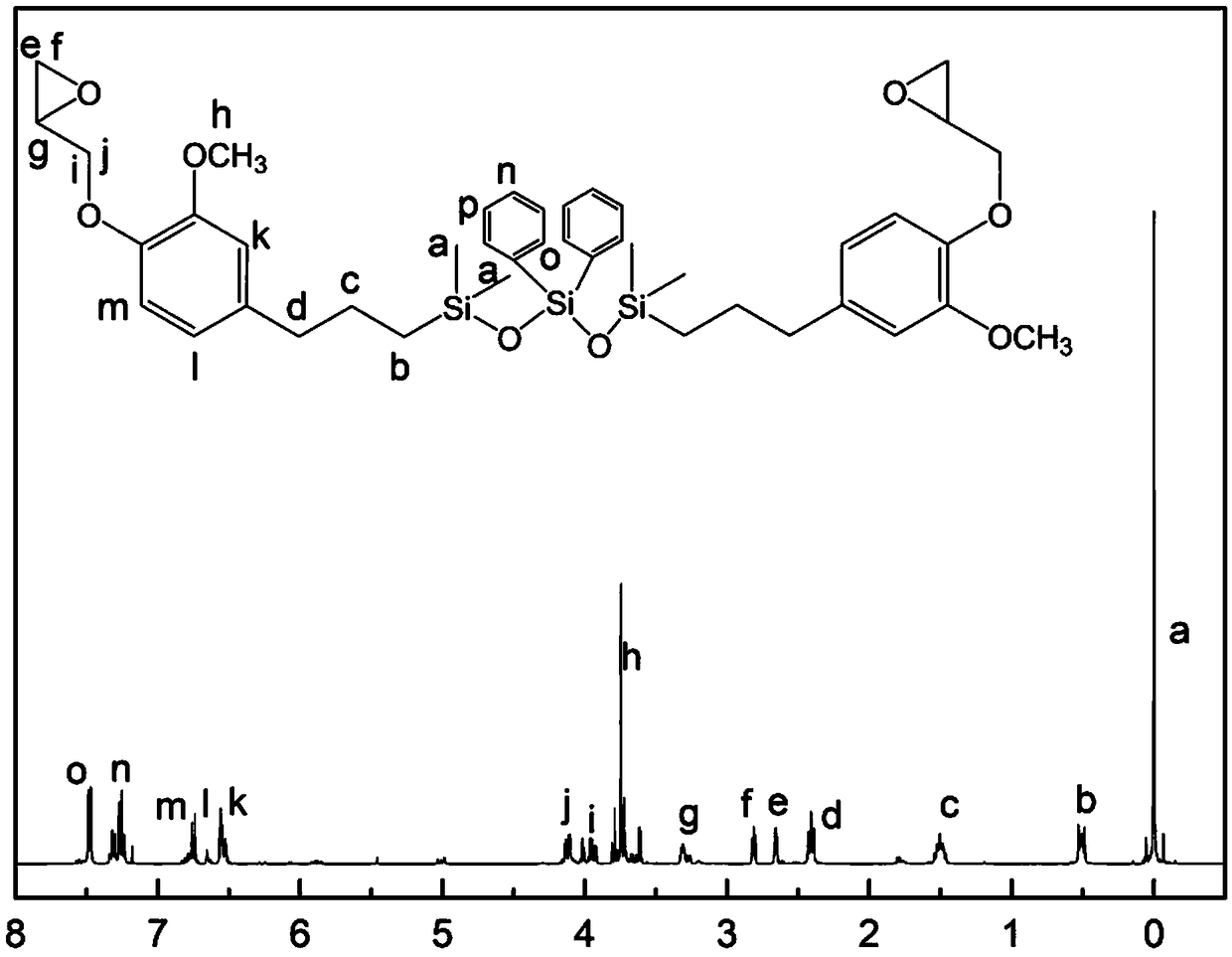

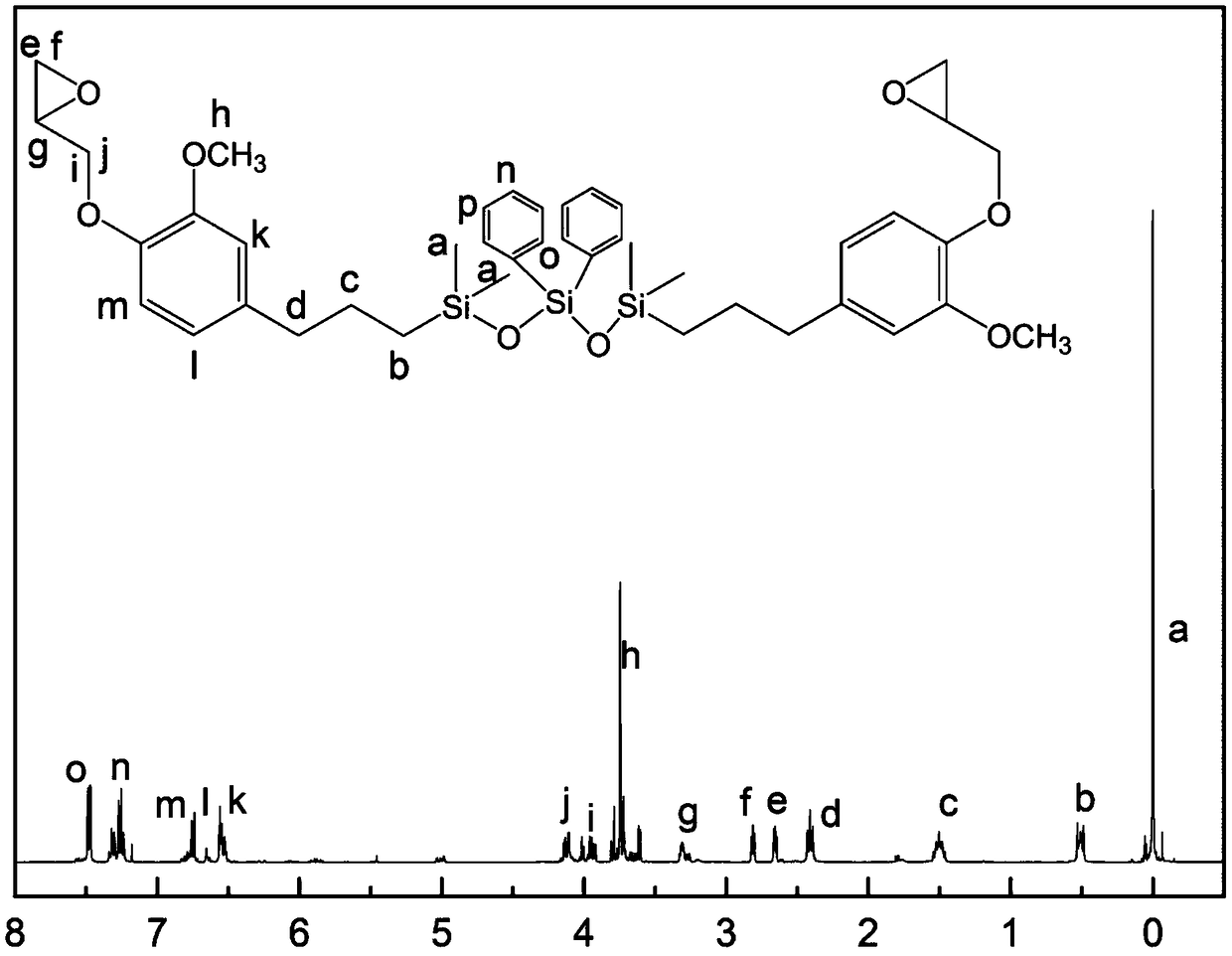

InactiveCN109467677AExcellent dielectric propertiesLow dielectric constantSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsCarbon numberEpoxy

The invention discloses a bio-based epoxy resin composition. The bio-based epoxy resin composition comprises the following raw materials: 100 parts of bio-based epoxy resin and 5 to 50 parts of a curing agent; and the structural general formula of the bio-based epoxy resin is shown in the following formula. In the formula, x is an integer selected from 1 to 5, R1 to R4 are independently selected from a phenyl, a vinyl group, and an alkyl group having 1 to 10 carbon numbers. The bio-based epoxy resin is siloxane chain segment-containing eugenol bio-based epoxy resin, and main reaction functional groups are eugenol epoxy groups, and siloxane chain segments are introduced in a molecular skeleton, thereby being capable of greatly reducing the viscosity of the system and improving the processing fluidity, siloxane in macromolecular volume can further greatly improve dielectric properties and reduce dielectric constants, and has intrinsic flame retardant properties. The epoxy resin composition taking siloxane as a substrate can realize intrinsic flame retardation without adding a flame retardant, and the epoxy resin film prepared by using the composition has outstanding flame retardancy,adhesive properties and bending strength, and further is high in dielectric strength.

Owner:江苏和和新材料股份有限公司

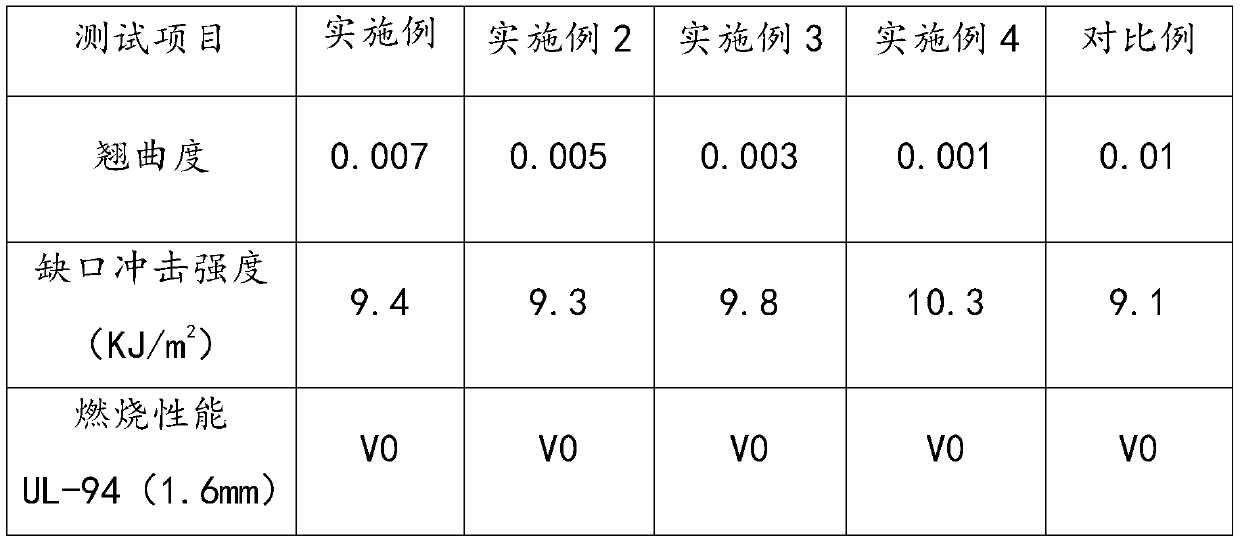

Reinforced flame-retardant low-warpage PBT alloy material and preparation method thereof

The invention discloses a reinforced flame-retardant low-warpage PBT alloy material and a preparation method thereof. The alloy material comprises the following components in parts by weight: 35-50 parts of polybutylene terephthalate, 5-15 parts of polycarbonate, 15-30 parts of glass fiber, 5-15 parts of an inorganic filler, 5-20 parts of a compound flame retardant, 5-10 parts of a toughening agent, 0.2-0.4 parts of a compound antioxidant, 0.1-0.3 parts of a lubricant, 0.1-0.3 parts of an ester exchange inhibitor, and 0.1-0.3 parts of an anti-dripping agent. The preparation method comprises the following steps: uniformly mixing all the materials except the glass fiber at a high speed, respectively feeding the mixed material and the glass fiber into a main feeding hole and a side feeding hole of a double-screw extruder, and finally forming the material. The amorphous polymer PC is introduced into the raw materials, so that the crystallinity of the system is reduced, the warping propertyof the PBT material is improved, and the PBT can be reinforced and toughened; and a compound flame retardant is introduced, so that the product has a flame-retardant characteristic. Finally, the PBT / PC alloy material has good mechanical properties, flame retardance and warping resistance, so that the application range of the PBT / PC alloy material in the fields of high-grade electrical components,household electrical shells and the like is expanded.

Owner:中广核瑞胜发(厦门)新材料有限公司

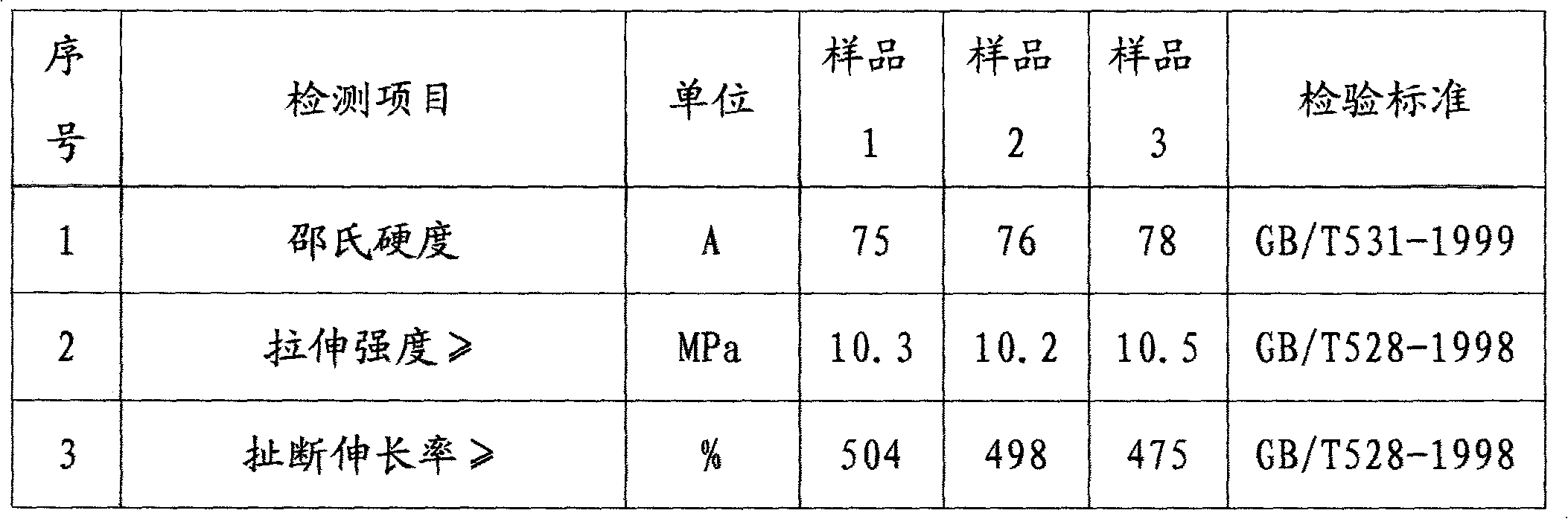

Environment-friendly and flame retarded rubber material of inside liner of fire hose and preparation method thereof

InactiveCN101831117AGood weather resistanceWith flame retardant propertiesFlexible pipesRubber materialPolymer science

The invention discloses an environment-friendly and flame retarded rubber material of an inside liner of a fire hose and a preparation method thereof. The rubber material is prepared from the following raw materials in parts by weight: 100 parts of chlorinated polyethylene rubber, 10-15 parts of magnesium oxide, 0-8 parts of zinc oxide, 2-10 parts of thermal stabilizer, 15-20 parts of carbon black, 15-30 parts of white carbon black, 10-20 parts of citric acid plasticizer, 60-100 parts of aluminium hydroxide, 2-8 parts of adhesive, 2-5 parts of vulcanizing agent and 1.5-3 parts of co-vulcanizing agent. The method comprises the following steps of: placing the chlorinated polyethylene rubber, the thermal stabilizer, the magnesium oxide, the zinc oxide, the carbon black, the white carbon black, the aluminium hydroxide, the adhesive and the citric acid plasticizer into an internal mixer, mixing for 120-240 s, then adding the vulcanizing agent and the co-vulcanizing agent to continuously mix for 30-60 s, complementally mixing for 200-400 s on an open mill after discharging, and then pressing into sheet rubber suitable for processing on a tablet press.

Owner:WEIFANG YAXING GRP CO LTD

Eugenol-based epoxy resin and preparation process and application thereof

InactiveCN109400638AImprove catalytic performanceImprove flame retardant performanceSilicon organic compoundsEpoxyHalloysite

The invention discloses a preparation process of eugenol-based epoxy resin. The preparation process comprises the steps that (1) eugenol, epichlorohydrin and a catalyst A are added under the normal pressure, etherification ring-opening reaction is conducted at the temperature of 90-120 DEG C, thus chlorinol ether is prepared, and the catalyst A is a halloysite nanotube immobilized with benzyl triethyl ammonium chloride; (2) when a system obtained through reaction in the step (1) is cooled to 40-80 DEG C, alkali is added into the system, heat preservation for reaction is conducted for 1-12 h,then still standing and cooling layering are conducted, and thus collected organic phase products are epoxidized eugenol; and (3) the epoxidized eugenol prepared in the step (2), siloxane containing hydrogen at the two ends, and a catalyst B are mixed, hydrosilylation is conducted, and thus the eugenol-based epoxy resin is prepared. According to the preparation process, the bio-based eugenol serves as an initial raw material, and a prepared eugenol-based epoxy resin curing material simultaneously has the excellent flame retardant property, bonding property and electrical property.

Owner:ZHEJIANG UNIV

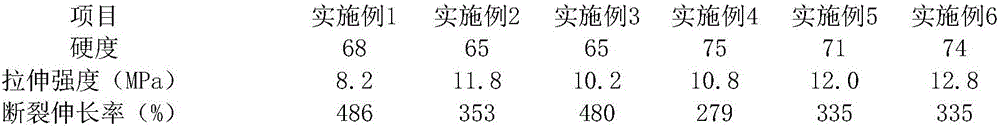

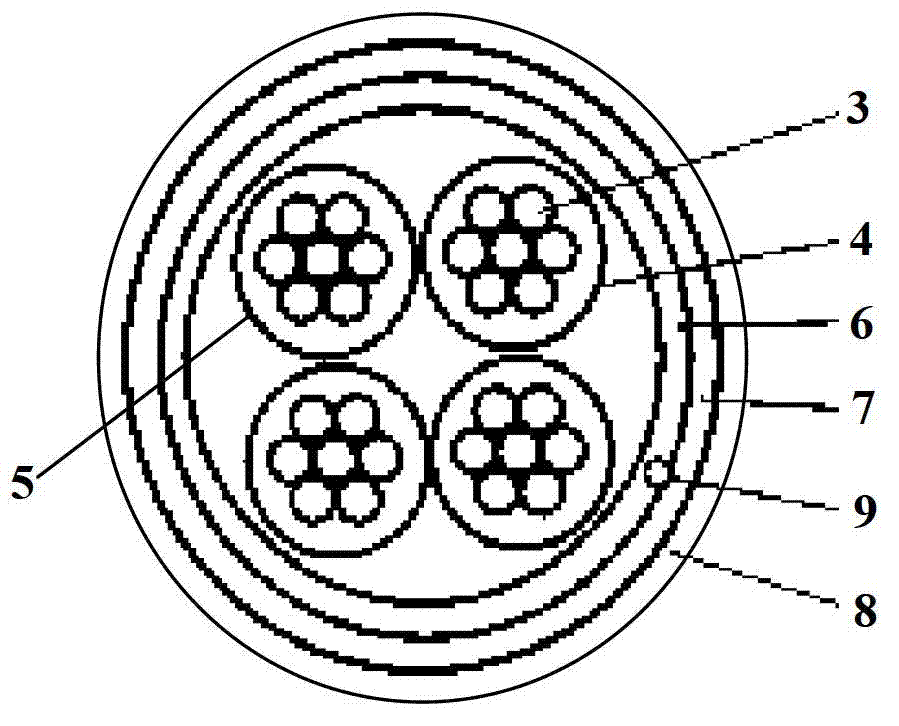

Environment-friendly type low-smoke flame-retardant insulated rubber composition, preparation method, use and product applying composition

InactiveCN106380706AWith flame retardant propertiesSimple production processPolymer scienceEthylene-propylene-diene-monomer

The invention discloses an environment-friendly type low-smoke flame-retardant insulated rubber composition, a preparation method, a use and a product applying the composition. The composition comprises the following components in parts by weight: 100 parts of ethylene propylene terpolymer, 10-40 parts of carbon black, 0-50 parts of white carbon black, 0-160 parts of a flame retardant, 10-50 parts of a plasticizer, 1-4 parts of an anti-ageing agent and 3.5-5.5 parts of a vulcanizing agent. The environment-friendly type low-smoke flame-retardant insulated rubber composition has flame resistance on the basis of excellent characteristics of the ethylene propylene terpolymer, is simple in production process and is low in cost.

Owner:NANJING ORIENTLEADER TECH CO LTD

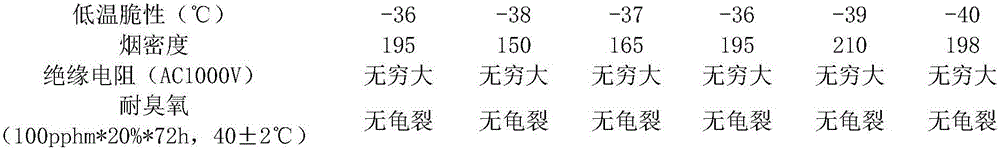

Flame retardant fire-resistant track traffic signal flexible cable

ActiveCN102768879AGuaranteed softnessImprove the ability to resist interference between groupsClimate change adaptationCommunication cablesPolyesterThermal ageing

The invention discloses a flame retardant fire-resistant track traffic signal flexible cable, which comprises at least three shielding line sets wrapped by a first polyester band, wherein each of the shielding line sets comprises at least two twisted single lines formed by twisting seven first tinned copper wires; each of the twisted single lines is provided with a single line insulation layer on the external surface; the at least two twisted single lines are wrapped by a second polyester band provided with a line resistance shielding layer; a line resistance insulation layer is wrapped on the external surface of each line resistance shielding layer; and each single line insulation layer is composed of an external single line insulation layer and an internal single line insulation layer; each external single line insulation layer comprises the following materials: 1%-3% of true crosslinked polyethylene and 97%-99% of plastic color masterbatch; and each external line resistance insulation layer comprises synthetic mica paper, of which both sides are covered by fiberglass cloth through silicon resin adhesive layers. The flexible cable provided by the invention can eliminate influences on the electric field by metal particles in the color masterbatch distributed around a conductor, lower transmission attenuation of the cable, and improve the mechanical performances as well as light and thermal ageing resistance of the insulation layers.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Production method of inorganic flame retardant fabric

InactiveCN103397512AWith flame retardant propertiesImprove flame retardant propertiesFibre treatmentTetrabromobisphenol ATetra

The invention relates to a production method of an inorganic flame retardant fabric. The production method comprises the following steps of: (1) dissolving magnesium hydrate and aluminum hydroxide into an ammonium salt solution; (2) soaking a fabric raw material into the solution obtained in the step (1), and drying the soaked fabric raw material which is taken out; (3) spinning the fabric raw material obtained in the step (2) to form a fabric, soaking the fabric in the solution obtained in the step (1) and stirring the solution in the soaking process; and (4) taking the fabric obtained in the step (3) out, drying the fabric in an environment with the temperature being higher than 45 DEG C, flatly and oppositely spreading the fabric obtained in the step (4), and spraying tetra bromobisphenol A onto the surface of the fabric. According to the production method disclosed by the invention, the fabric raw material has flame retardance; after the raw material is spun into the fabric, the fabric is further soaked with the magnesium hydrate and aluminum hydroxide solution and sprayed with the tetra bromobisphenol A, so that a flame retardant agent is attached to the surface of the fabric, and therefore the flame retardance of the fabric is enhanced.

Owner:XUZHOU HUA SHENG TEXTILE

Bio-based epoxy resin as well as preparation process and application thereof

InactiveCN109384906AImprove catalytic performanceImprove flame retardant performanceSilicon organic compoundsEpoxyMolecular sieve

The invention discloses a preparation process of bio-based epoxy resin, the preparation process comprises: 1), adding eugenol, epoxy chloropropane and a catalyst A under normal pressure, carrying outetherification open-loop reaction at the temperature of 90-120 DEG C to prepare chlorhydrin ether; wherein the catalyst A is a mesoporous molecular sieve catalyst immobilized with benzyl triethyl ammonium chloride; 2) cooling the system obtained in the step 1) to 40-80 DEG C, adding an alkali into the system, and carrying out heat preservation reaction for 1-12 hours, standing, cooling and layering, and collecting an organic phase product, namely epoxy eugenol; and 3) and mixing the epoxy eugenol prepared in the step 2) and siloxane containing hydrogen at the two ends with a catalyst B, and carrying out hydrosilylation reaction to prepare the bio-based epoxy resin. The preparation process disclosed by the invention takes the bio-based eugenol as an initial raw material, and the prepared bio-based epoxy resin cured product has excellent flame retardancy, adhesive property and electrical property.

Owner:江苏和和新材料股份有限公司

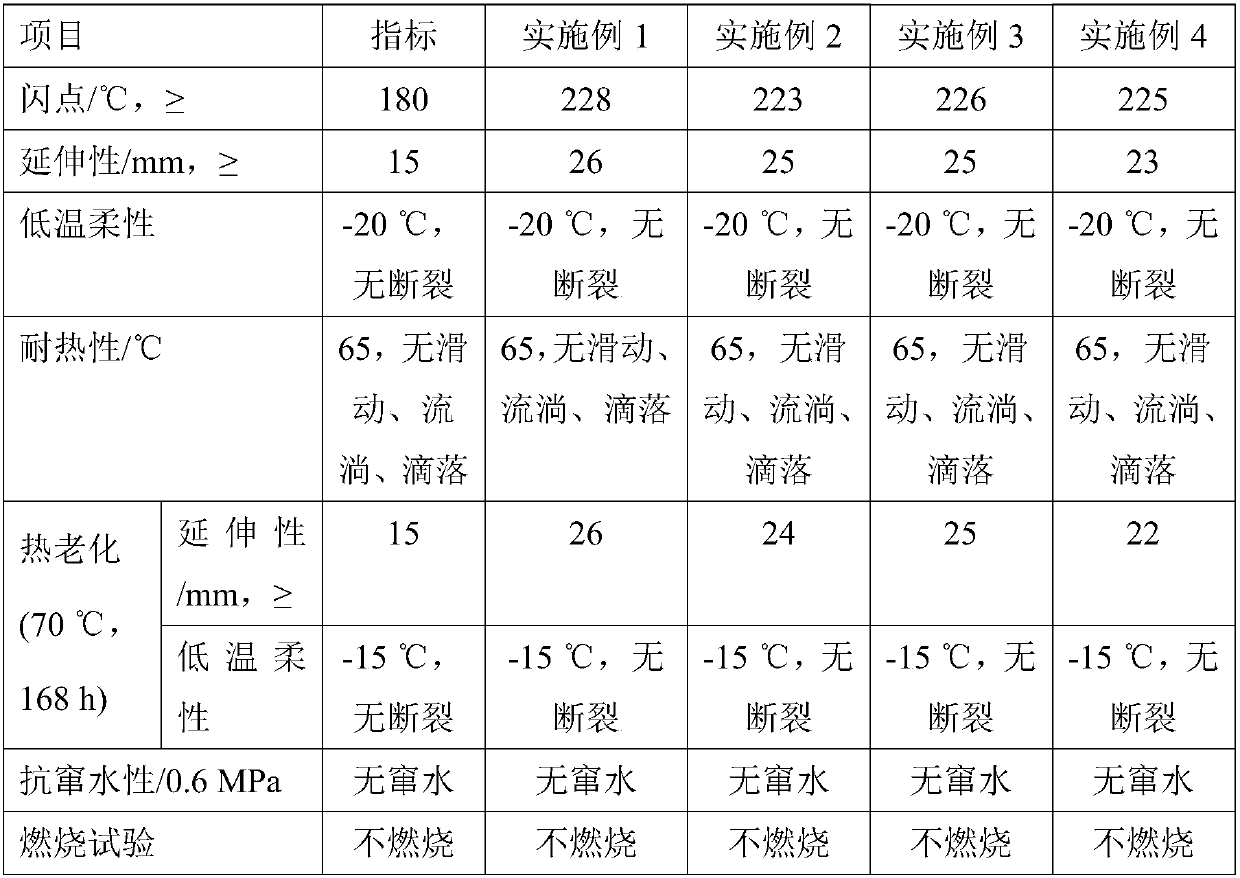

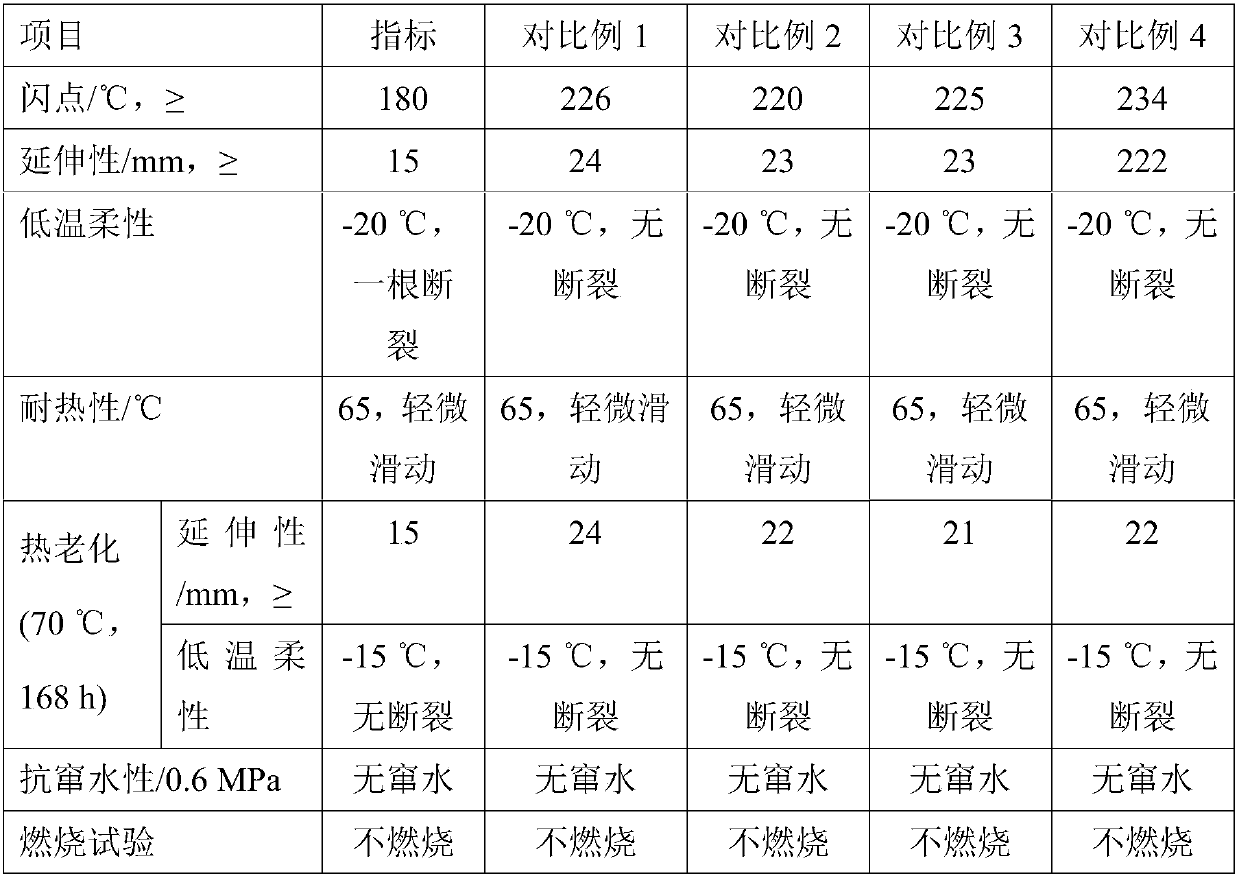

Viscosity-reducing flame-retardant type non-cured rubber asphalt waterproof coating and preparation method thereof

InactiveCN110724454AViscosity reduction hasViscosity reduction flame retardant hasFireproof paintsOther rubber coatingsWaste rubberFire retardant

The invention belongs to the technical field of building waterproof materials, and particularly relates to a viscosity-reducing flame-retardant type non-cured rubber asphalt waterproof coating and a preparation method thereof. The waterproof coating is prepared from the raw materials in parts by weight: 30-60 parts of petroleum asphalt, 10-30 parts of a softener, 3-10 parts of a modifier SBS, 5-20parts of a tackifier, 5-20 parts of waste rubber powder, 5-25 parts of a filler, 3-10 parts of a flame retardant and 2-6 parts of a flowability-increasing agent. The waterproof coating provided by the invention has multiple characteristics such as water resistance, viscosity reduction, easy flowing, flame retardance and the like, the construction temperature and energy consumption are reduced, the non-cured rubber asphalt waterproof coating is prevented from fire in construction and application, and the safety of the non-cured rubber asphalt waterproof coating is enhanced. According to the preparation method provided by the invention, the dissolution difficulty of the modifier in the mixture is lowered, on one hand, the dissolution of the modifier is facilitated, and on the other hand, the preparation temperature of the non-cured rubber asphalt waterproof coating is lowered, and the energy is saved.

Owner:CHINA PETROLEUM & CHEM CORP

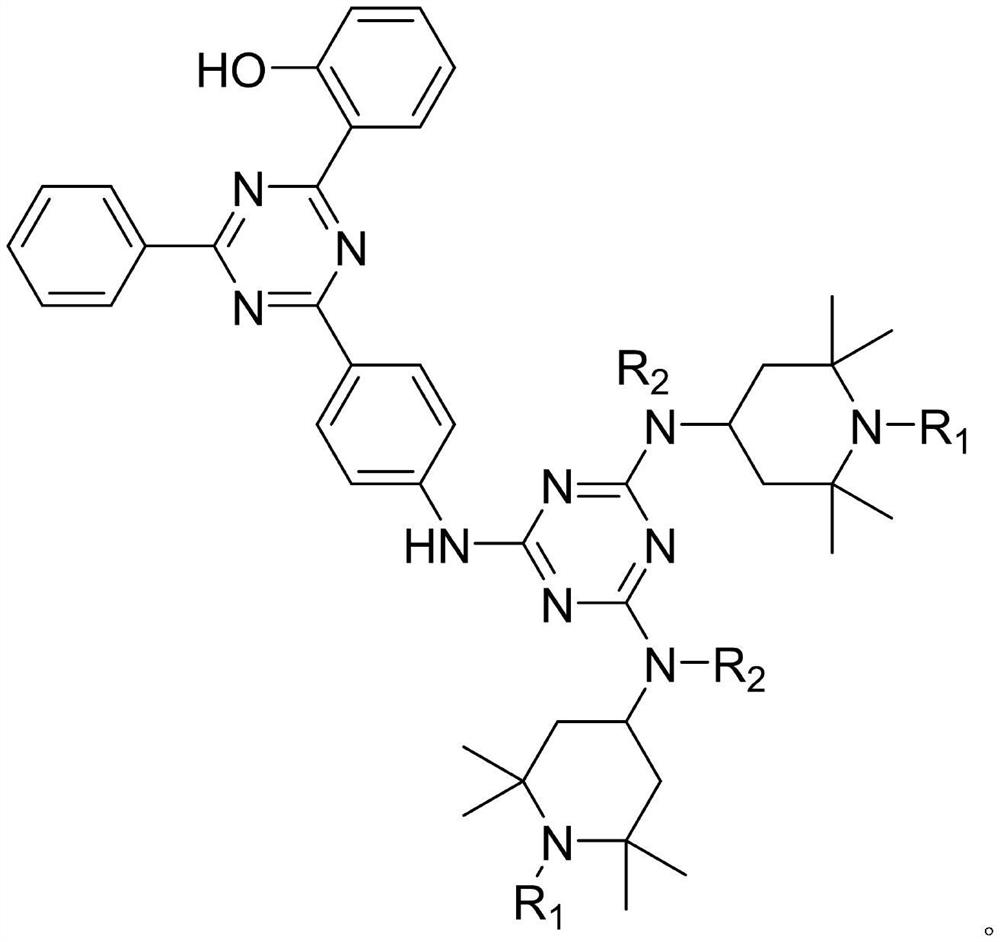

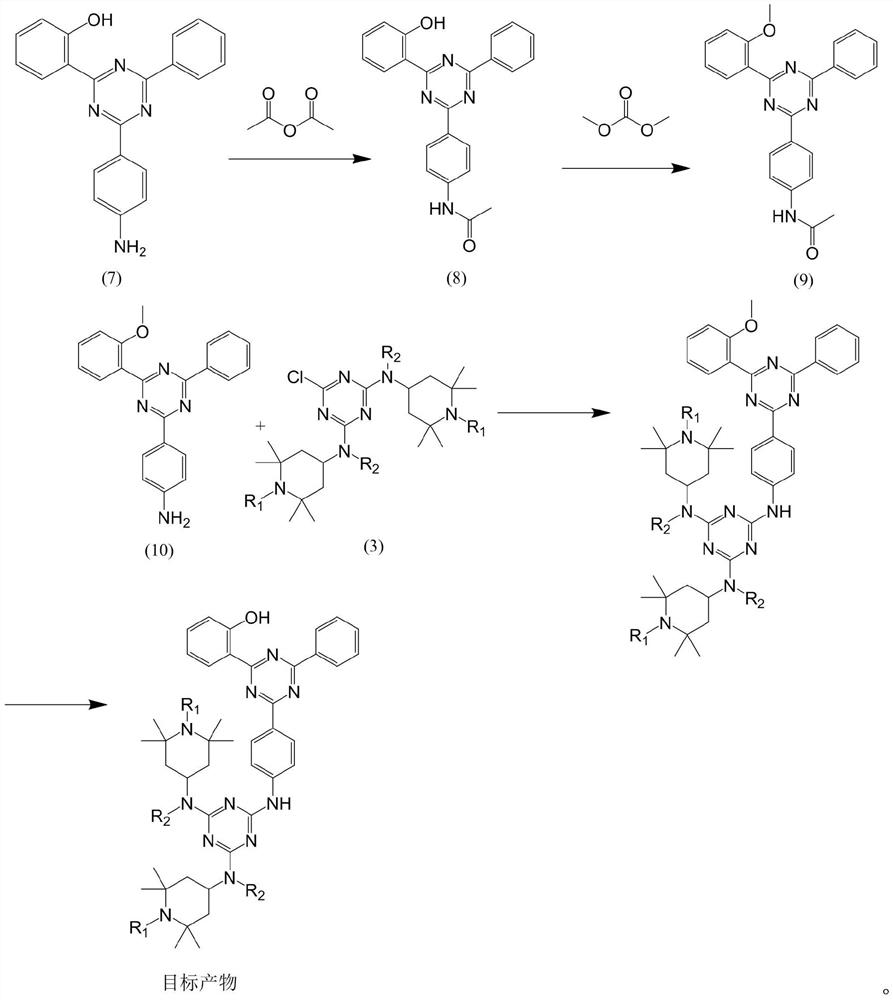

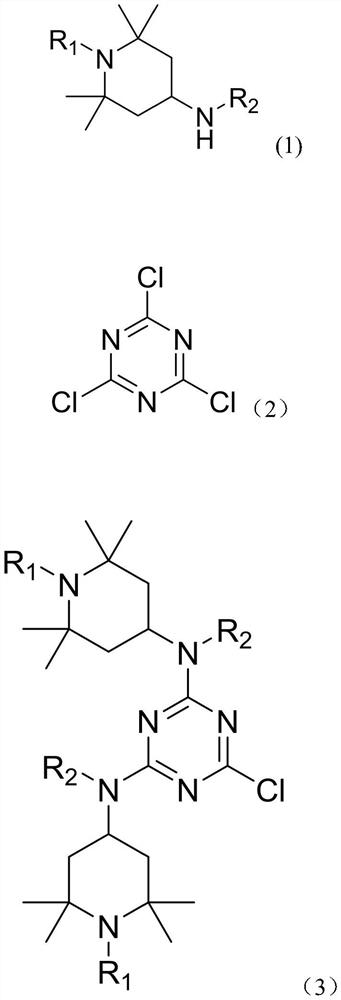

Preparation method of multifunctional light stabilizer

PendingCN111875584AExcellent UV absorption spectral characteristicsWith flame retardant propertiesOrganic chemistryChemistryOxygen atom

The invention provides a preparation method of a multifunctional light stabilizer, and particularly relates to the field of light stabilizers; the structure of the multifunctional light stabilizer isshown as follows, wherein the R1 is any one of oxygen, hydrogen, hydroxyl, halogen, C1-C20 alkyl, C4-C10 naphthenic base, C1-C12 alkoxy, C4-C12 naphthenyloxy, C1-C10 chain enyloxy or cyclic enyloxy, C1-C10 cyano substituted alkyloxy and C1-C15 aromatic alkoxy; and R2 is hydrogen, a C1-C20 alkyl group or an oxygen atom substituted C1-C20 alkyl group. The triazine multifunctional light stabilizer with the double hindered amine piperidine groups can be prepared, and the triazine multifunctional light stabilizer has more excellent ultraviolet absorption spectrum characteristics, free radical capturing capacity and high polymer compatibility and also has certain flame retardant characteristics.

Owner:ZHENXING FINE CHEM CO LTD

Production method for phosphorus inflaming-retarding fabrics

InactiveCN103397515AWith flame retardant propertiesImprove flame retardant propertiesFibre treatmentSulfateFire - disasters

The invention relates to a production method for phosphorus inflaming-retarding fabrics. The manufacturing method comprises the following steps of: (1) selecting pure red phosphorus, and carrying out micronization; (2) dissolving ammonium phosphate into water, uniformly stirring, and soaking fabric raw materials into the ammonium phosphate solution; (3) weaving the fabric raw materials obtained in the step (2) into cloth, soaking the cloth into the ammonium phosphate solution again, taking out the cloth, and carrying out air drying on the cloth; and (4) spraying the red phosphorus obtained in the step (1) to the surface of the cloth, spraying a sulfate solution to the surface of the cloth, and carrying out the air drying on the cloth in a breeze environment until the sulfate solution is hardened into a layer of film adhering to the surface of the cloth. According to the production method for the phosphorus inflaming-retarding fabrics, sufficient flame retardants are adhered to the surfaces of the fabric raw materials and the cloth, and the fire cannot be spread by the fabrics when the fabrics are burnt up in a burning process, so that the development of a fire disaster can be stopped, and the damages of the fire disaster to human can be reduced.

Owner:XUZHOU HUA SHENG TEXTILE

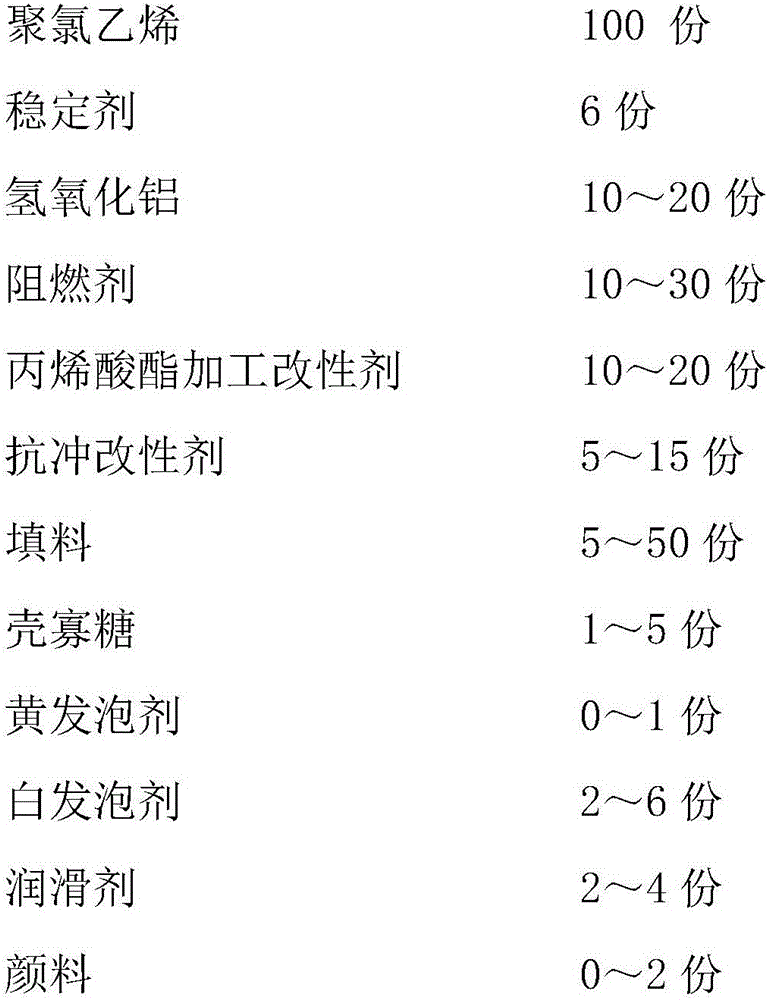

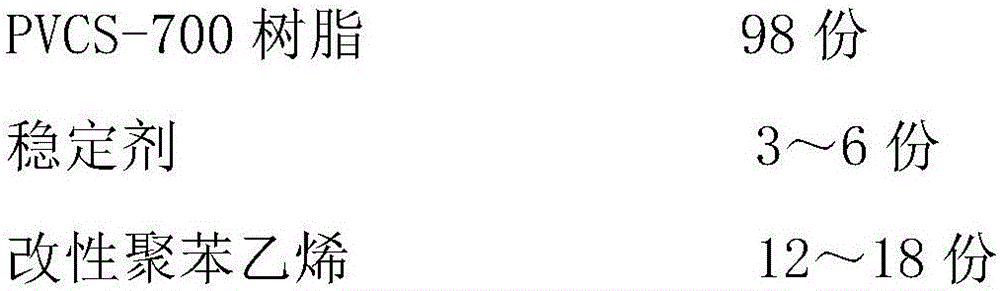

Hard environment-friendly flame-retardant polyvinyl chloride foaming board and manufacturing method thereof

InactiveCN106142790AHigh hardnessLow densitySynthetic resin layered productsEnvironmental resistanceFire retardant

The invention discloses a hard environment-friendly flame-retardant polyvinyl chloride foaming board and a manufacturing method thereof. The foaming board comprises a lower layer. A second surface layer is connected to the upper surface of the lower layer. A third surface layer is connected to the upper surface of the second surface layer. An ASA resin layer is connected to the upper surface of the third surface layer. A protective film layer is arranged on the upper surface of the ASA resin layer. The lower layer polyvinyl chloride foaming material is prepared from, by weight, 100 parts of polyvinyl chloride, 6 parts of a stabilizing agent, 10-20 parts of aluminum hydroxide, 10-30 parts of flame retardant, 10-20 parts of an acrylic ester processing modifier, 5-15 parts of an impact modifier, 5-50 parts of a filler, 1-5 parts of a chitosan oligosaccharide, 0-1 part of a yellow foaming agent, 2-6 parts of a white foaming agent, 2-4 parts of a lubricating agent, and 0-2 parts of pigment. The hard environment-friendly flame-retardant polyvinyl chloride foaming board has the advantages of being high in hardness and low in density, resisting to water and dampness, resisting to flame, being environmentally friendly and the like, is easy to implement, and has the good market prospect.

Owner:POTENTECH GUANGDONG

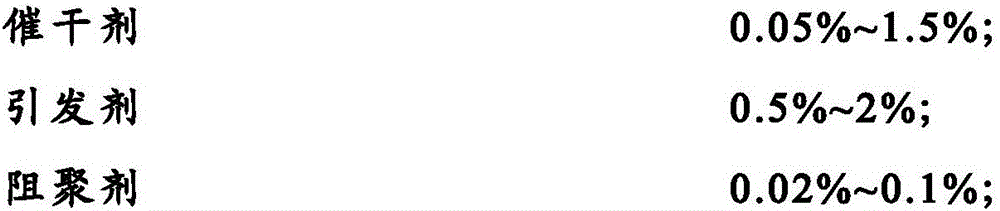

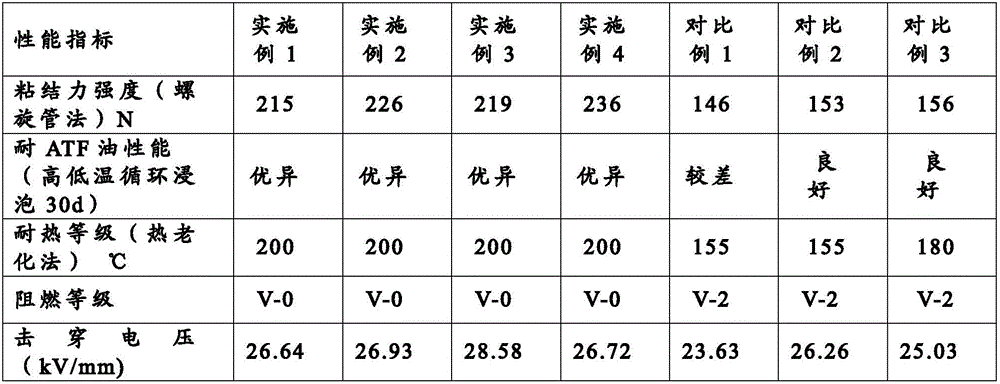

ATF oil resistant flame retardant type impregnated resin as well as preparation method and application thereof

The invention relates to ATF oil resistant flame retardant type impregnated resin as well as a preparation method and application thereof. The ATF oil resistant flame retardant type impregnated resin is prepared from the following raw materials in percentage by weight: 25-45 percent of modified epoxy resin, 15-37 percent of organic silicon resin, 5-15 percent of benzoxazine resin, 30-52 percent of a crosslinking monomer, 1-10 percent of a curing agent, 0.05-1.5 percent of a drying catalyst, 0.5-2 percent of an initiator and 0.02-0.1 percent of an polymerization inhibitor; the modified epoxy resin is prepared by enabling novolac epoxy resin to carry out esterification with acrylic acid and maleic anhydride sequentially; and the organic silicon resin is prepared by carrying out reaction on diphenylsilanediol and a double bond containing silane coupling agent. The impregnated resin has the characteristics of excellent transmission oil resistance, flame retardancy, heat resistance, high bonding strength and the like and is suitable for insulation impregnating treatment of an oil cooling type electric vehicle drive motor.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

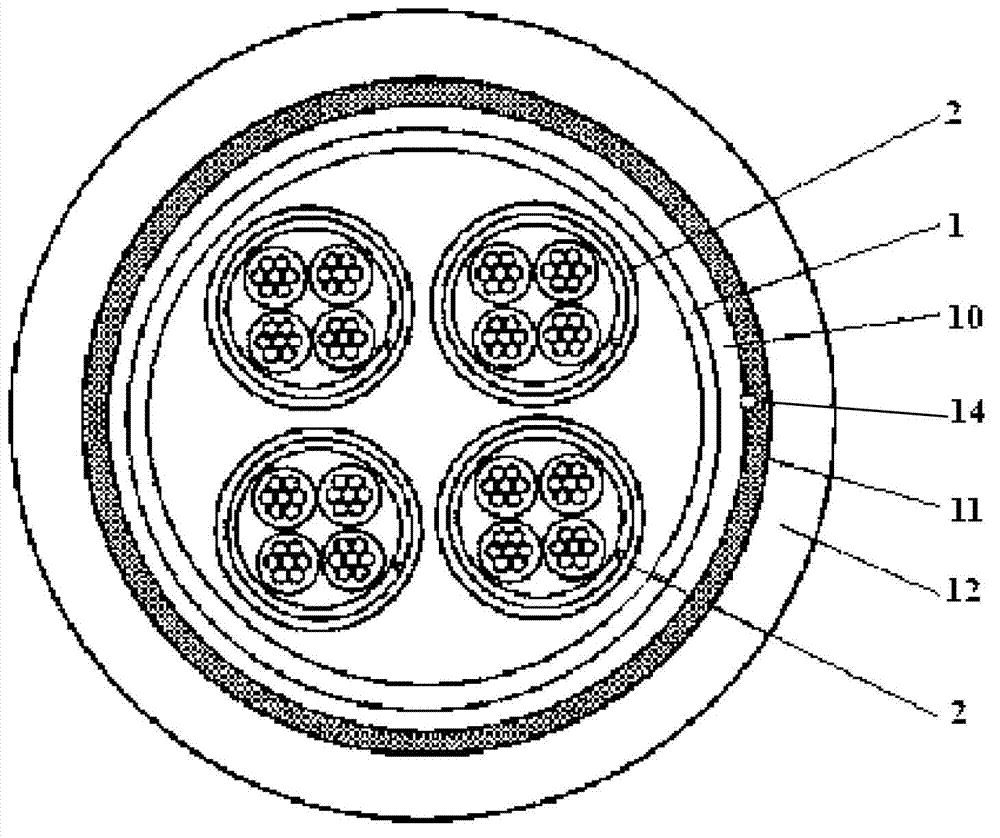

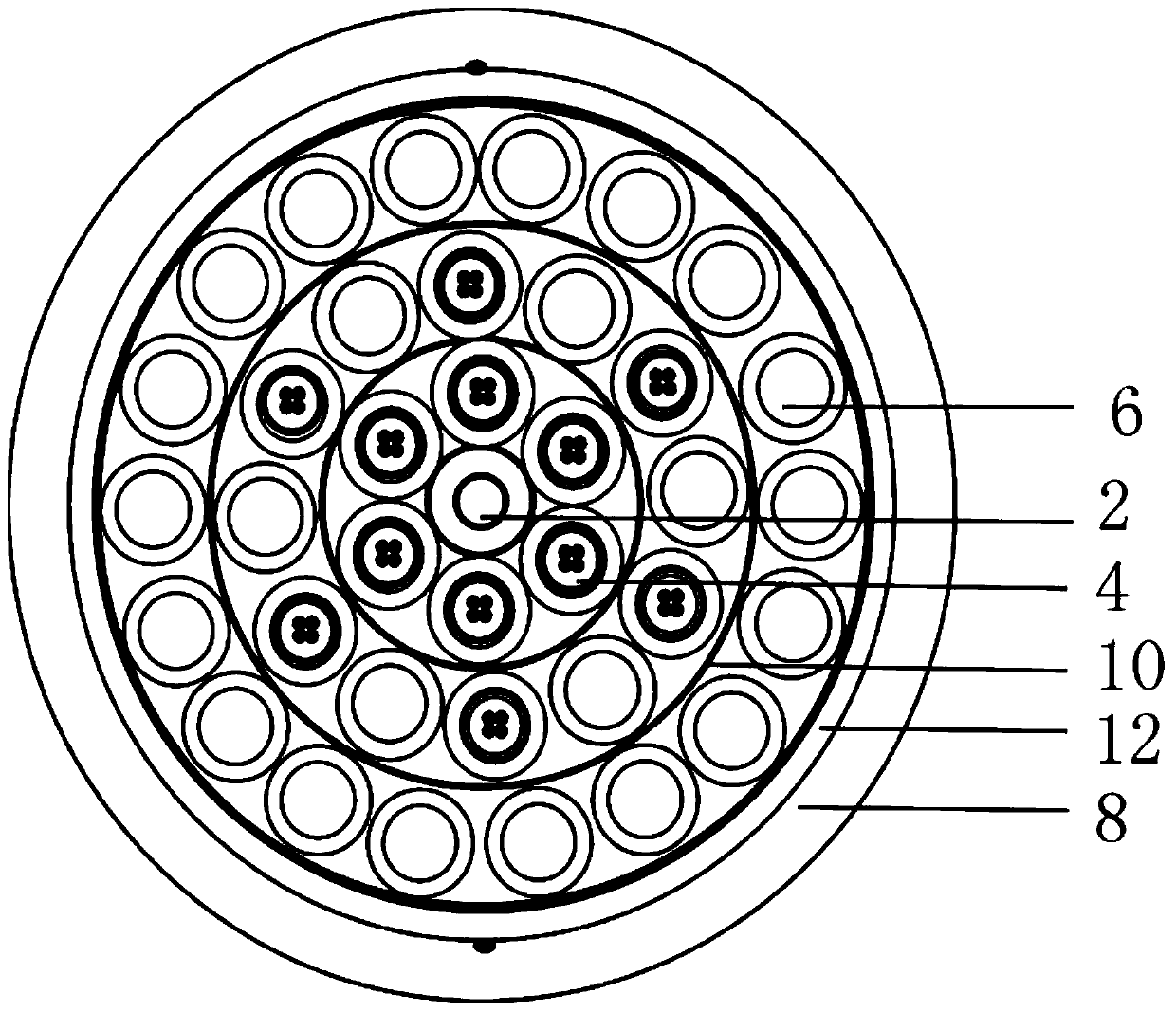

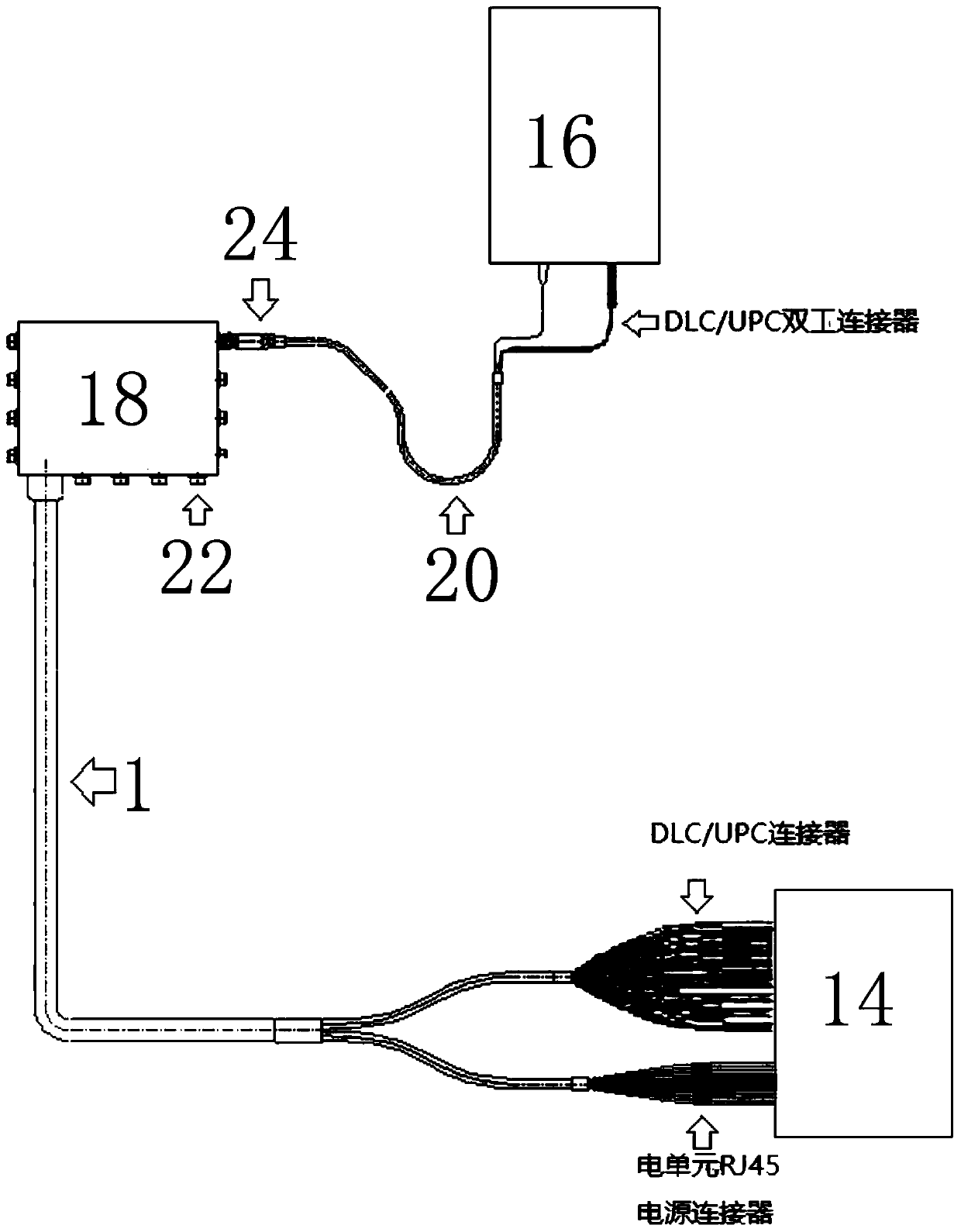

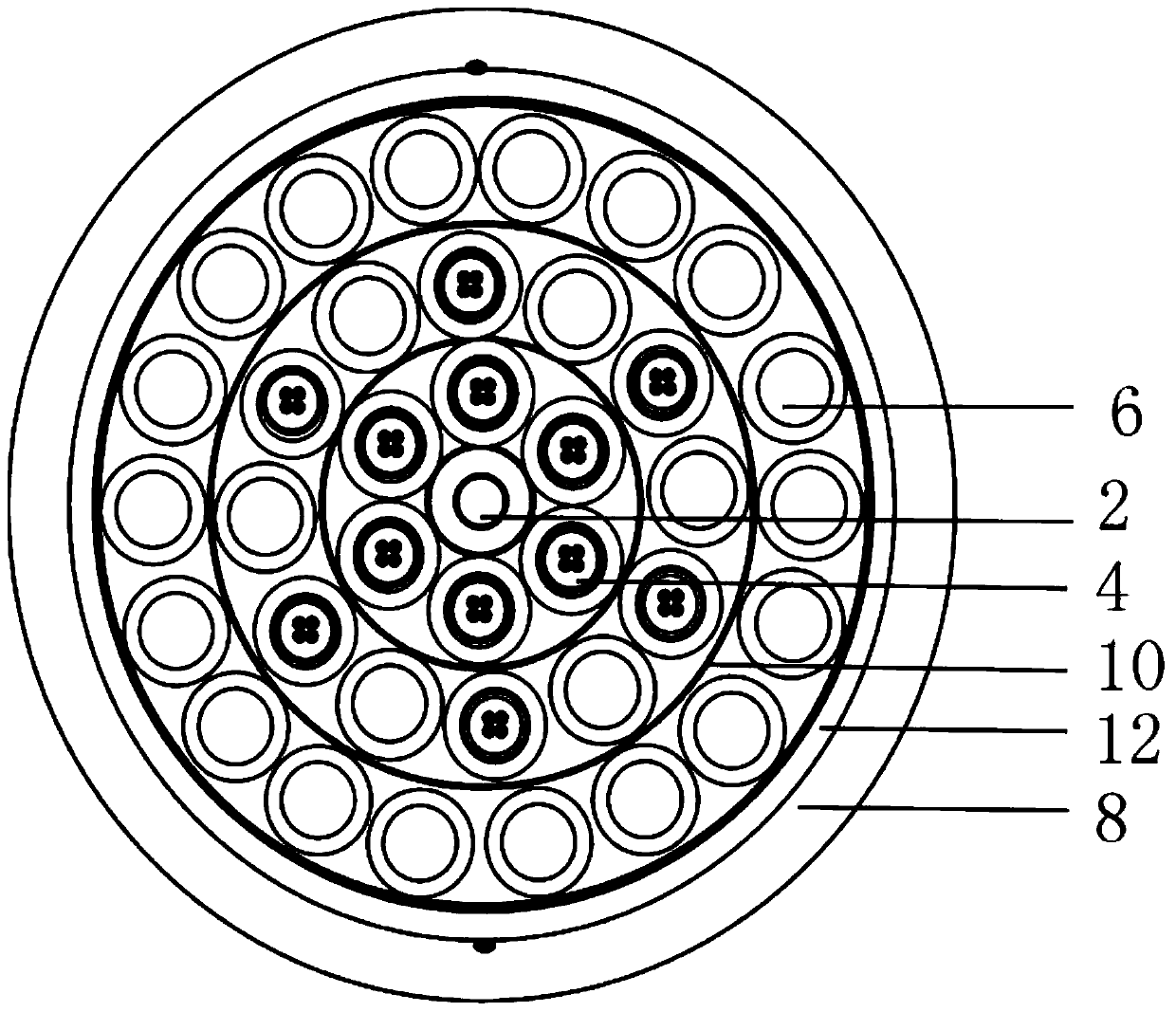

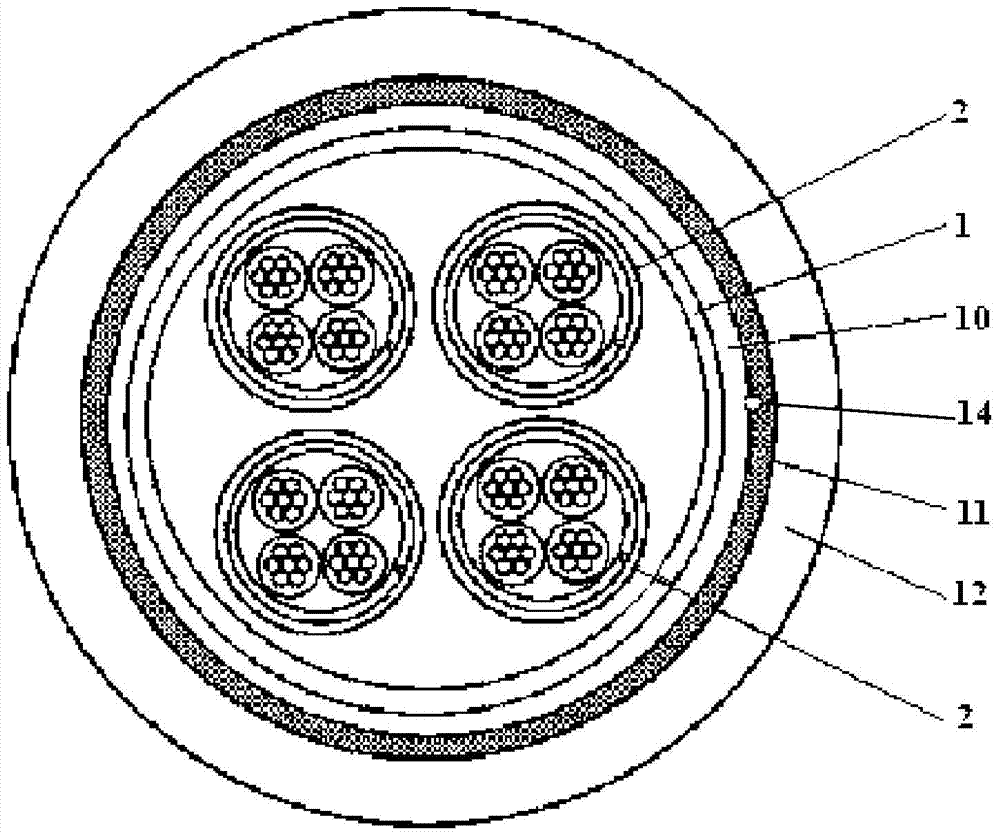

Photoelectric composite cable and application thereof in 5G front-haul network

PendingCN109979666AWith flame retardant propertiesImprove wear resistanceFibre mechanical structuresPower cables including optical transmission elementsElectricityEngineering

The invention discloses a photoelectric composite cable, and further relates to application of the photoelectric composite cable in a 5G front-haul network. The photoelectric composite cable comprisesa central reinforcer, an optical signal layer coating the central reinforcer, a photoelectric hybrid layer coating the optical signal layer, and an electric signal layer coating the photoelectric hybrid layer, wherein the optical signal layer is provided with a plurality of optical units; the photoelectric hybrid layer is provided with a plurality of electric units and a plurality of optical units, and the electric units and the optical units are alternately arranged; the electric signal layer is provided with a plurality of electric units; and each optical unit is provided with four opticalfibers, and each electric unit is provided with a cell. According to the photoelectric composite cable, a cable is processed by adopting a mode of combining the optical units and the electric units, so that the photoelectric composite cable is compact in structure, small in occupied space, easy to construct, low in comprehensive cost and convenient to lay and use; the photoelectric composite cableis applied to the 5G front-haul network, communication and power supply problems of multiple devices can be solved from BBU and RRU ends of a base station by only one cable, and the comprehensive cost of laying of drop cables of the base station is reduced.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

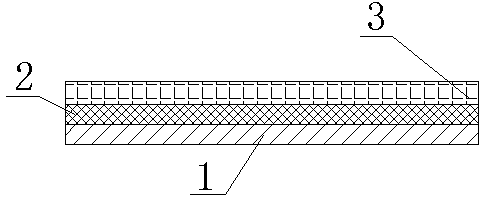

Ultraviolet-proof viscose acetal fiber fabric

InactiveCN103434242AWith UV protection effectWith flame retardant propertiesCellulosic plastic layered productsWoven fabricsUltravioletEngineering

The invention discloses an ultraviolet-proof viscose acetal fiber fabric which comprises an ultraviolet-proof layer (3), a flame-retardant layer (2) under the ultraviolet-proof layer (3), and a viscose acetal fiber base cloth layer (1) under the flame-retardant layer (2), wherein the viscose acetal fiber base cloth layer (1) is formed by weaving a plurality of viscose acetal fibers, which are taken as warps and wefts, by a weaving machine; the flame-retardant layer (2) is attached to the viscose acetal fiber base cloth layer (1) in a soaking way. As being provided with the ultraviolet-proof layer and the flame-retardant layer, the ultraviolet-proof viscose acetal fiber fabric has an ultraviolet-proof effect and flame retardance at the same time, and is simple to manufacture, safe and reliable.

Owner:SUZHOU HONGYOU TEXTILE

Up-conversion light diffusion micro-sphere for panel display and preparation method thereof

ActiveCN107175054AHigh luminous intensityGood stabilityMicroballoon preparationMicrocapsule preparationChemistryComposite oxide

The invention discloses an up-conversion light diffusion micro-sphere for panel display and a preparation method thereof. The panel display up-conversion light diffusion micro-sphere is of a multi-shell structure and is microscopically of a sandwich structure. Erbium and magnesium bimetal composite oxide Er2O3-MgO micro-spheres are arranged on the innermost layer, the average diameter of the erbium and magnesium bimetal composite oxide Er2O3-MgO micro-spheres is 2-4 micrometers, porous g-C3N4 is arranged on intermediate layers, the thicknesses of the intermediate layers are 100-200 nm, polysiloxane condensation polymers are arranged on the outermost layer, and the thickness of the outermost layer is 400-600 nm. The panel display up-conversion light diffusion micro-sphere and the method have the advantages that a layer of porous g-C3N4 grows on each Er2O3-MgO micro-sphere in an in-situ manner to prepare porous g-C3N4 / Er2O3-MgO composite micro-spheres, and siloxane monomers are hydrolyzed, condensed and polymerized on the composite micro-spheres in an in-situ manner to obtain the panel display up-conversion light diffusion micro-sphere, accordingly, the panel display up-conversion light diffusion micro-sphere has up-conversion luminescence phenomena, and green light can be generated by the panel display up-conversion light diffusion micro-sphere excited by laser devices with the wavelengths of 980 nm; excellent light diffusion effects can be realized by light diffusion films prepared from the panel display up-conversion light diffusion micro-sphere by means of ultraviolet curing, the visible light transmittance of the light diffusion films is 90%-95%, the haze of the light diffusion films is 80%-88%, the light diffusion films have up-conversion luminescence performance and are excellent in mechanical performance, ageing resistance and flame-retardant characteristic and have multiple functions, and accordingly the up-conversion light diffusion micro-sphere for the panel display and the method are extensive in application prospects.

Owner:SOUTHEAST UNIV

Up-converting light-diffusing microspheres for flat panel display and preparation method thereof

ActiveCN107175054BImprove stabilityHigh luminous intensityMicroballoon preparationMicrocapsule preparationUltravioletGreen-light

The invention discloses an up-conversion light diffusion micro-sphere for panel display and a preparation method thereof. The light diffusion micro-sphere is of a multi-shell structure and is microscopically of a "sandwich" structure. Erbium and magnesium bimetal composite oxide Er2O3-MgO micro-spheres are arranged on the innermost layer, and the average diameter of the micro-spheres is 2-4 μm; porous g-C3N4 is arranged on intermediate layers, and the thicknesses of the intermediate layers are 100-200 nm; polysiloxane condensation polymers are arranged on the outermost layer, and the thickness of the outermost layer is 400-600 nm. The light diffusion micro-sphere is prepared by: firstly growing a layer of porous g-C3N4 on each Er2O3-MgO micro-sphere in an in-situ manner to prepare porous g-C3N4 / Er2O3-MgO composite micro-spheres, and then hydrolyzing, condensing and polymerizing siloxane monomers on the composite micro-spheres in an in-situ manner, the panel display up-conversion light diffusion micro-sphere has up-conversion luminescence phenomena, and green light can be generated by the panel display up-conversion light diffusion micro-sphere excited by laser devices with the wavelengths of 980 nm. Excellent light diffusion effects can be realized by light diffusion films prepared from the panel display up-conversion light diffusion micro-sphere by means of ultraviolet curing, the visible light transmittance of the light diffusion films is 90%-95%, the haze of the light diffusion films is 80%-88%.

Owner:SOUTHEAST UNIV

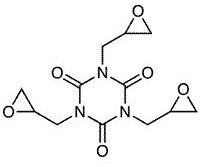

Heat-conducting pouring sealant and preparation method thereof

PendingCN113150728AEasy to useGuaranteed bonding functionNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceFirming agent

The invention discloses a heat-conducting pouring sealant and a preparation method thereof, the heat-conducting pouring sealant comprises a component A and a component B. The component A comprises 10-30 wt% of 1, 3, 5-triglycidyl isocyanurate; and the component B comprises 95.5 wt%-99.97 wt% of a curing agent. The preparation method comprises the following steps: mixing the 1, 3, 5-triglycidyl isocyanurate and the heat-conducting filler through an airflow mixer to obtain the component A; stirring and mixing a curing agent, a dispersing agent, a defoaming agent and a flatting agent to obtain a component B; and extruding the component A and the component B through a heatable single-screw extrusion device to obtain the heat-conducting pouring sealant. According to the invention, the self-flame-retardant resin and the curing agent are used as matrix materials, so that the use amount of the flame-retardant filler can be reduced, thereby reserving an increasing space for the heat-conducting filler for a system, ensuring that the amount of the resin is not changed, increasing the filling amount of the heat-conducting filler and further improving the heat-conducting property.

Owner:湖南创瑾技术研究院有限公司

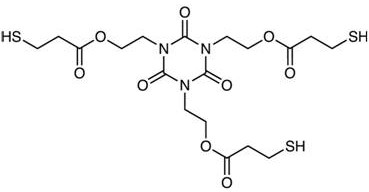

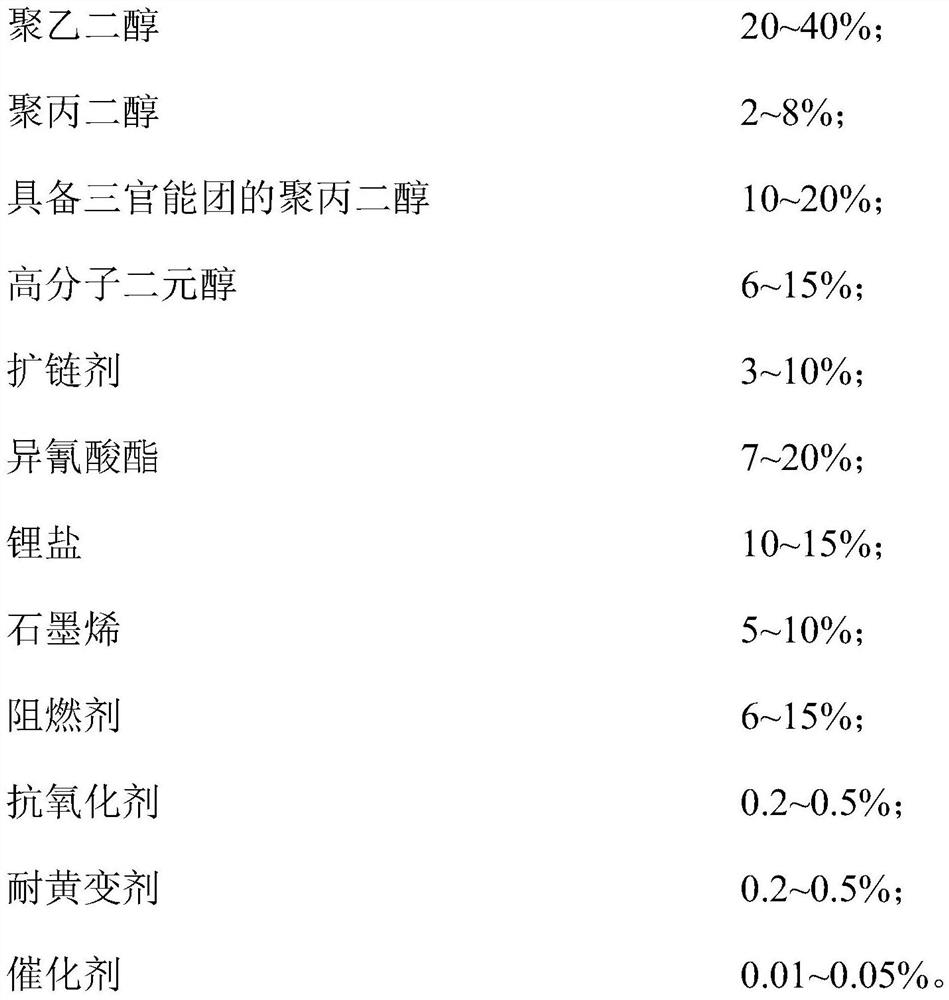

Preparation method of solid-liquid phase change type TPU electrolyte

PendingCN113480710AImprove securityImprove conductivitySolid electrolytesLi-accumulatorsPtru catalystAlcohol

A preparation method of solid-liquid phase change type TPU electrolyte comprises the following steps of: putting monomer glycols, adipic acid and tetrabutyl titanate into a reaction container for reaction to obtain macromolecular dihydric alcohol; putting polyethylene glycol, polypropylene glycol, polypropylene glycol with three functional groups, the macromolecular dihydric alcohol, a chain extender, isocyanate, lithium salt, graphene, a flame retardant, an antioxidant, an anti-yellowing agent and a catalyst into a reaction container for reaction; baking the product through an oven; and finally put the product into an extruder for granulation to obtain the solid-liquid phase change type TPU electrolyte. The solid-liquid phase change type TPU electrolyte can be subjected to solid-liquid phase change along with the change of temperature, is in a solid state at normal temperature, is in a liquid state during use, and has excellent safety and electrical conductivity.

Owner:东莞市米儿塑胶原料有限公司

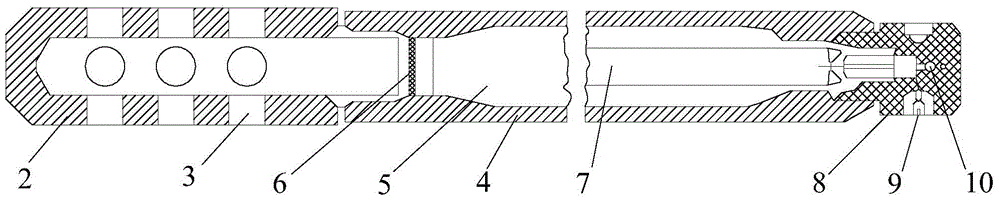

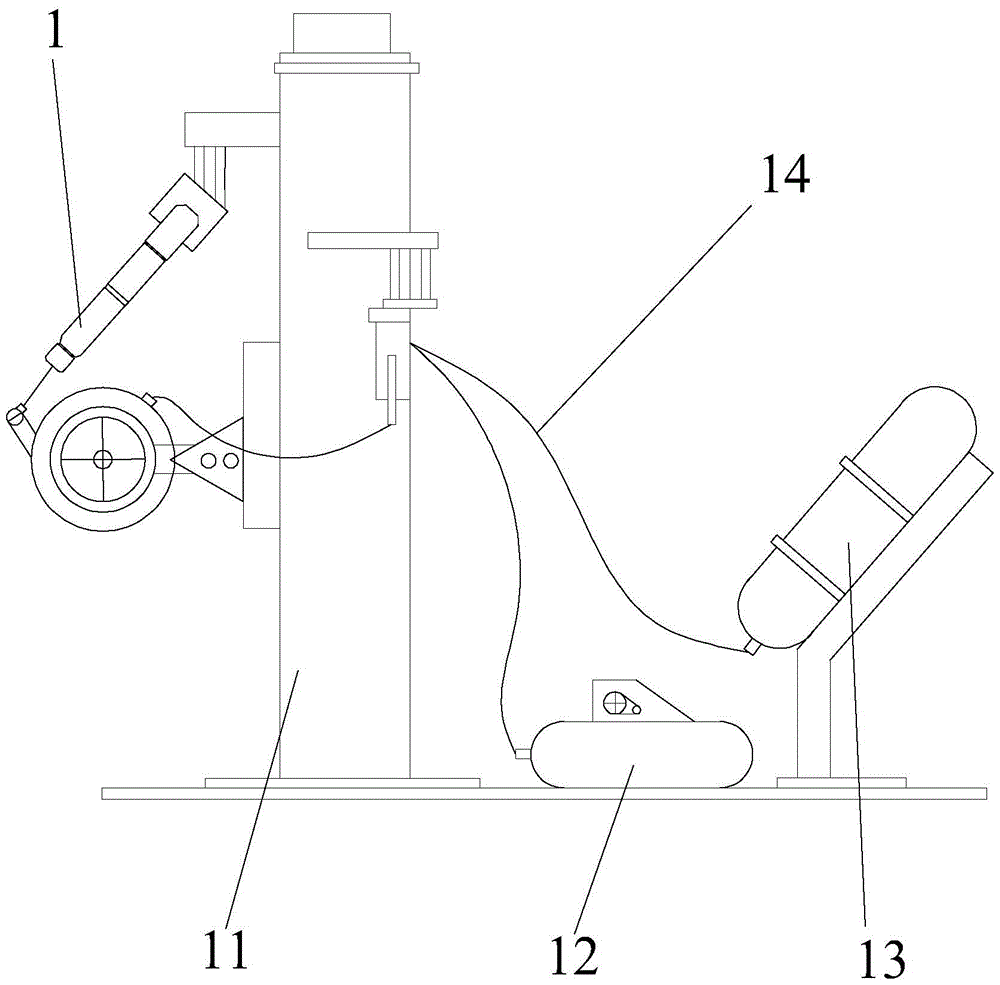

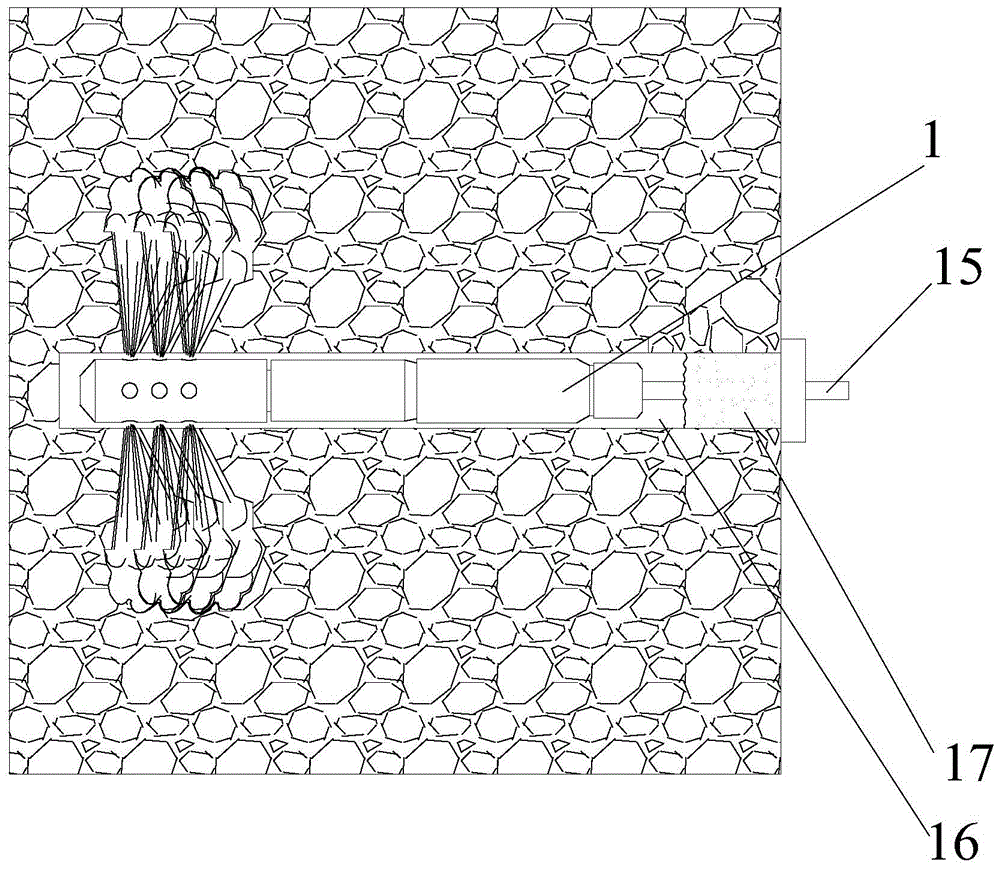

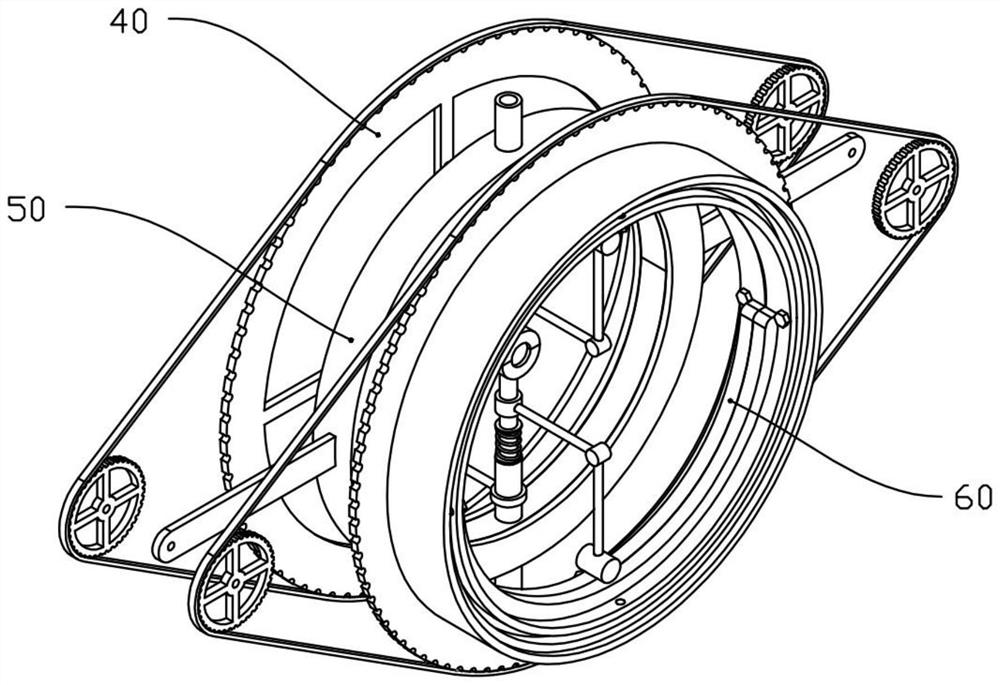

A method for gas drainage by pre-cracking high-stress and low-porosity coal seams

ActiveCN103806934BWith flame retardant propertiesChange the state of the original crackGas removalPorosityEngineering

The invention discloses a system and method for pre-splitting, anti-reflection, and gas drainage of high-stress and low-porosity coal seams, which includes a pre-splitting device, and the pre-splitting device includes an exhaust casing, and multiple gas outlets are evenly arranged on the exhaust casing. A vent hole, the rear part of the exhaust shell is provided with a blasting tube, the blasting tube is provided with a liquid carbon dioxide storage pipe, and the front end of the liquid carbon dioxide storage pipe entering the exhaust area is blocked with everything A variable disc, the liquid carbon dioxide storage pipeline is provided with a heating element; the rear end of the liquid carbon dioxide storage pipeline is provided with a liquid injection terminal, and the liquid injection terminal is provided with a liquid injection port, and the liquid injection port It communicates with the liquid carbon dioxide storage pipeline, and the liquid injection end is provided with an electrode for leading to the outside, and the electrode is connected with the heating element circuit. It can effectively increase the density and range of coal fractures, change the state of coal primary fractures, and improve the efficiency and safety of gas drainage.

Owner:SHANDONG UNIV OF SCI & TECH

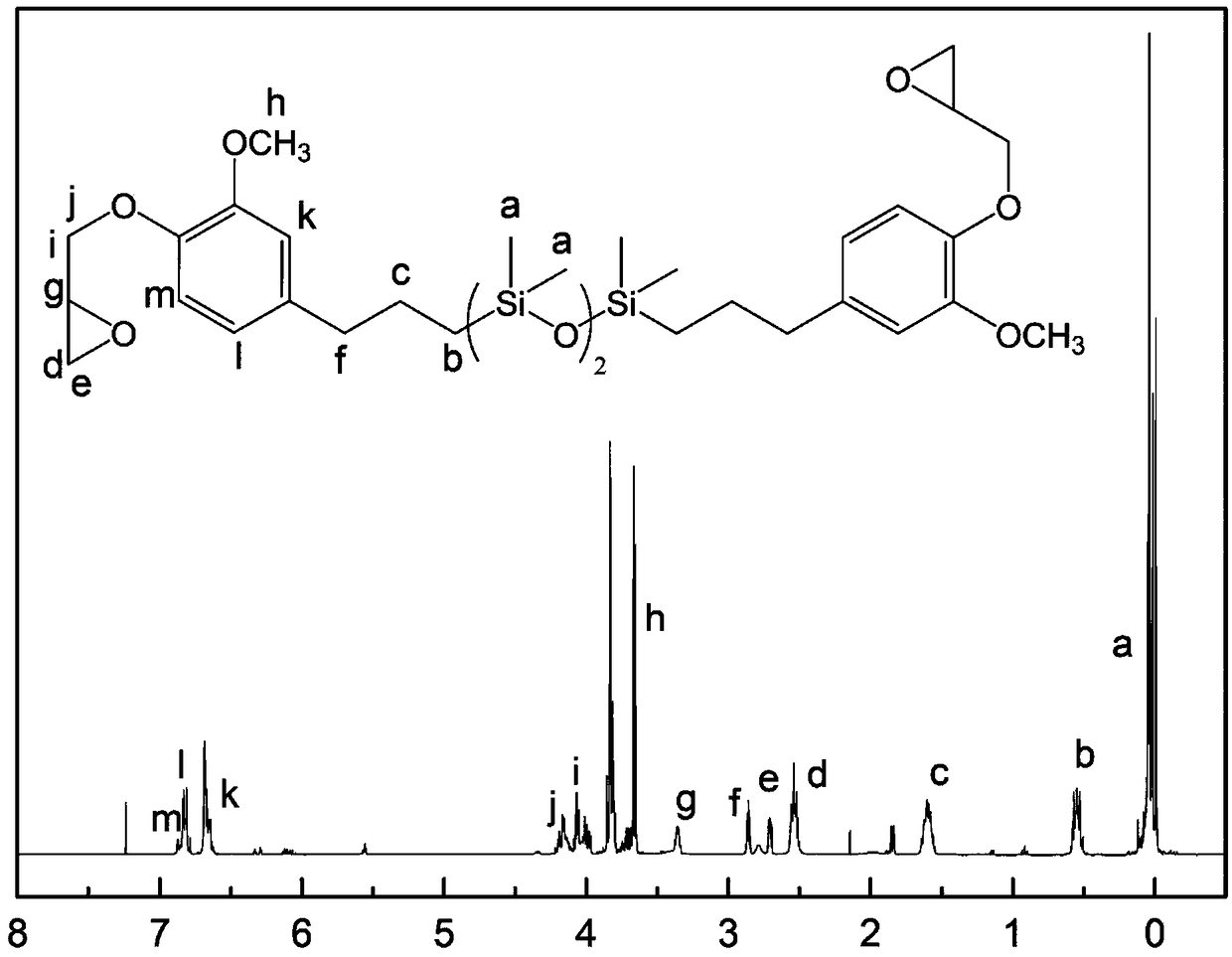

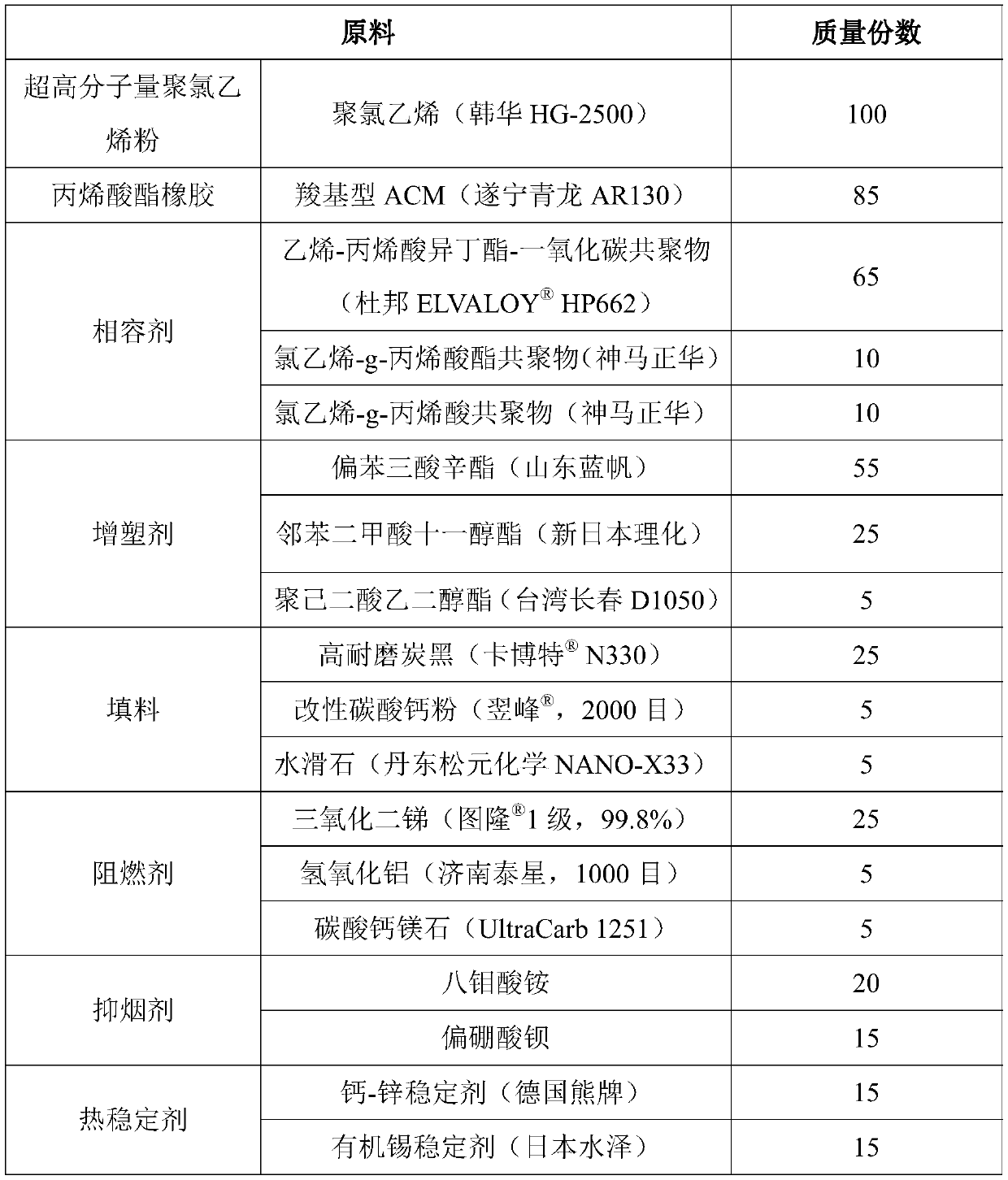

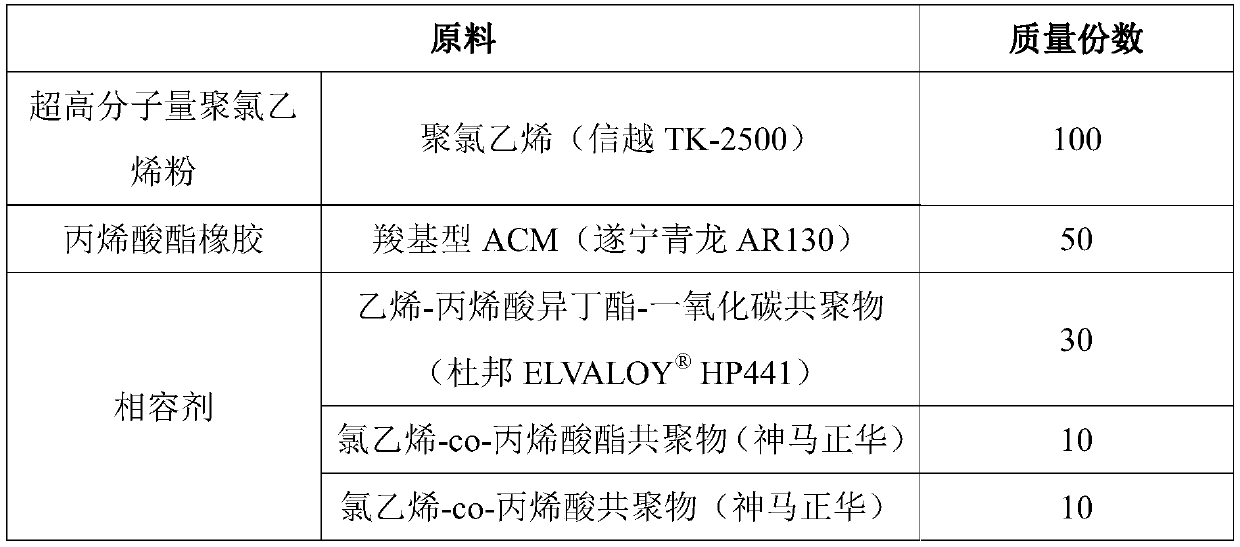

A thermoplastic dynamic vulcanization acrylate rubber composition and its preparation method

ActiveCN108047595BGood oil resistanceGood high and low temperature resistancePolymer scienceVulcanization

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

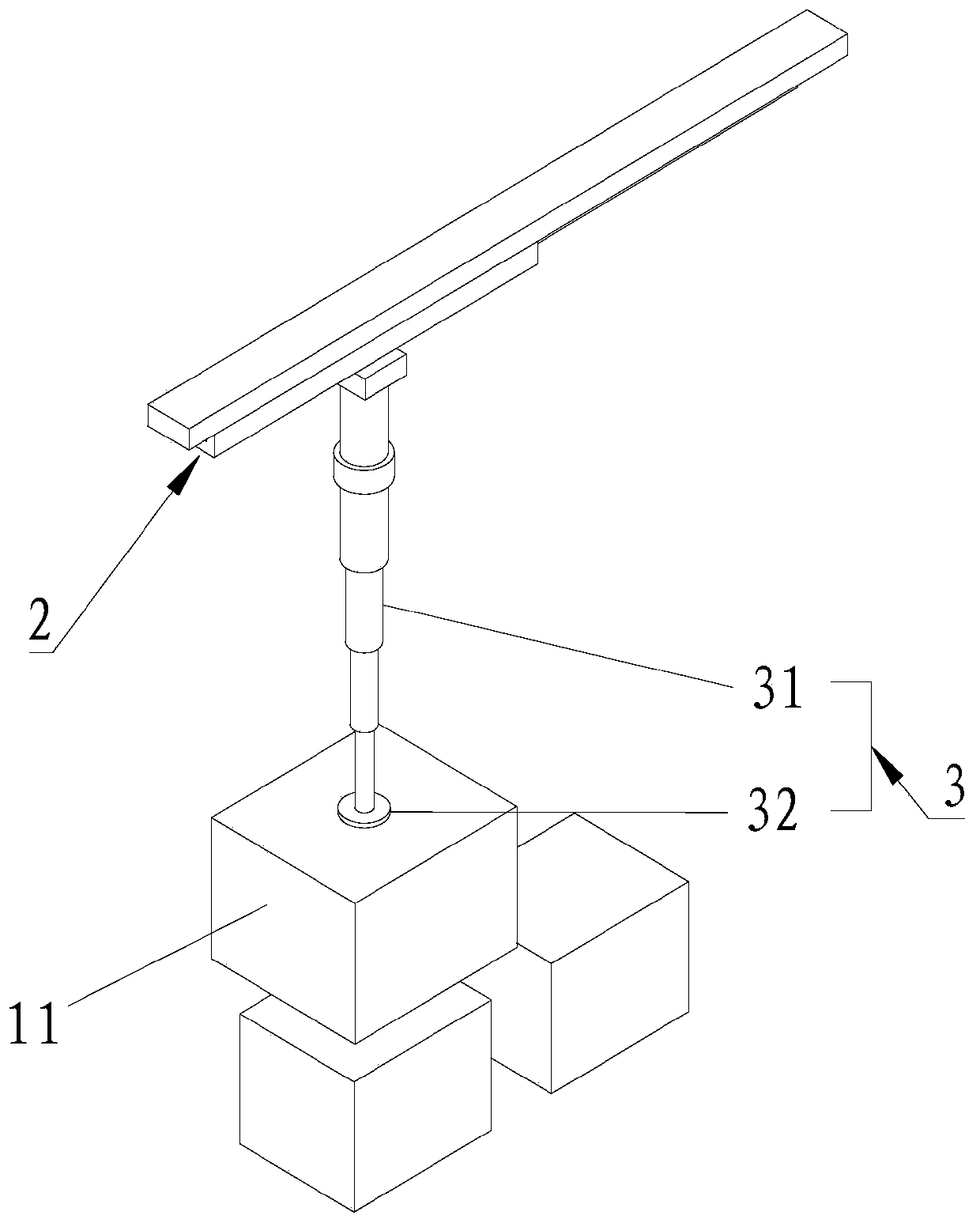

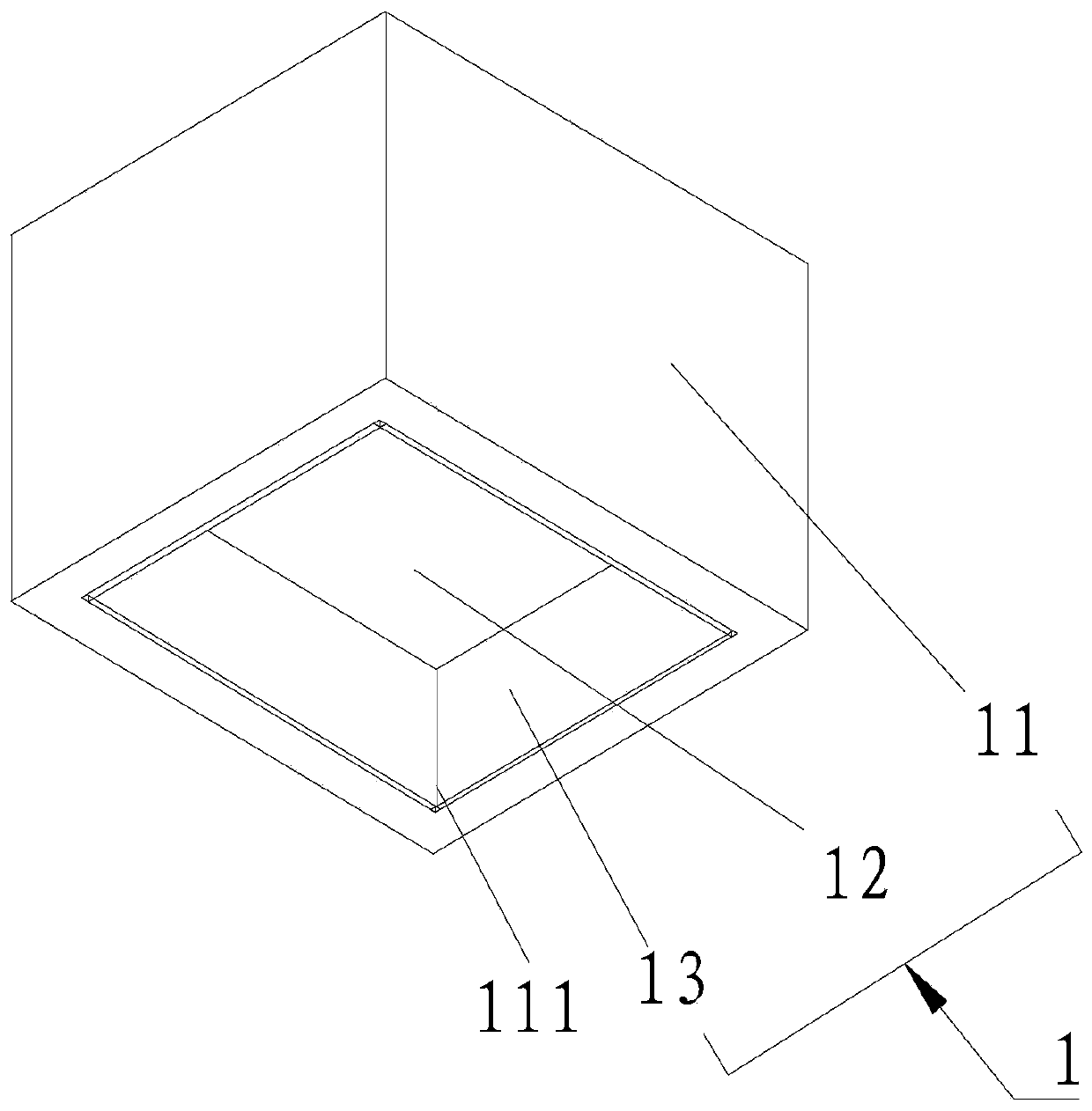

Furniture fire retardant treatment method and photocuring equipment

InactiveCN110918425AWith flame retardant propertiesImprove securityFireproof paintsPretreated surfacesMethacrylateArchitectural engineering

The invention discloses a furniture fire retardant treatment method and photocuring equipment. The method comprises the following step one of polishing, the step two of primary fire retardant coatingspraying, the step three of primary irradiation of UV, the step four of secondary fire retardant coating spraying, and the step five of secondary irradiation of UV. The fire retardant coating comprises the following components including 70-78 parts of vinyl ester resin, 5-10 parts of composite fire retardant agent, 3-7 parts of metacrylic acid ester, 1-3 parts of liquid wax, 0.6-1 part of photosensitizer, 0.3-0.6 part of antifoaming agent and 0.2-0.4 part of dispersing agent. The photocuring equipment comprises a UV irradiator, a sliding mechanism and a telescoping mechanism. The first slidingmechanism is installed on the top of a photocuring treatment chamber. The UV irradiator can be installed on the lower side of the sliding mechanism along the X-axis through the telescoping mechanism.According to the equipment, the photocuring efficiency is high, the attachment efficiency of the composite fire retardant agent is high, the production efficiency is improved, and adopted materials are environmentally friendly.

Owner:福州立雅家具有限公司

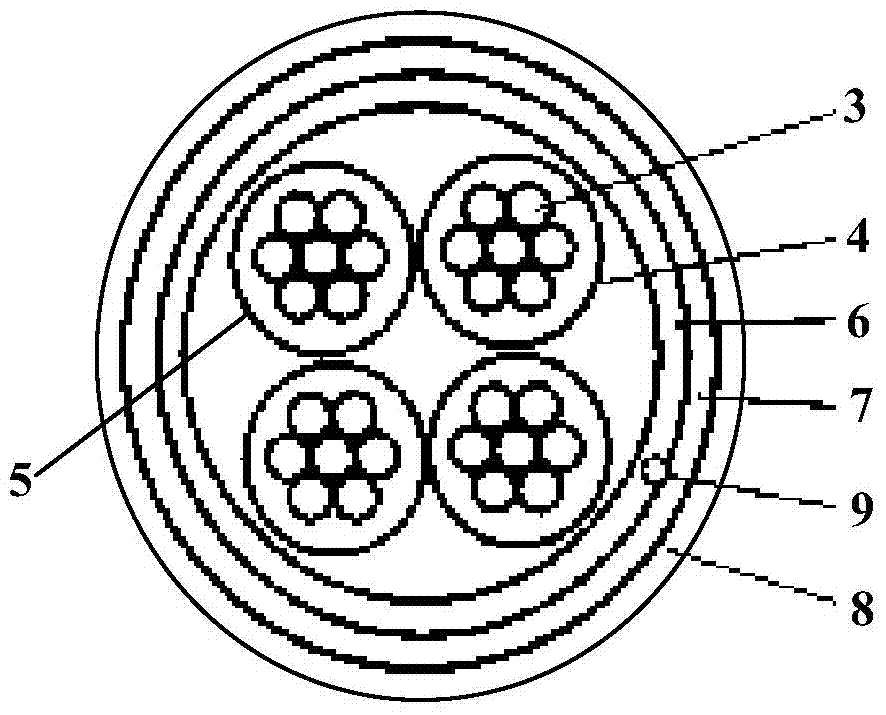

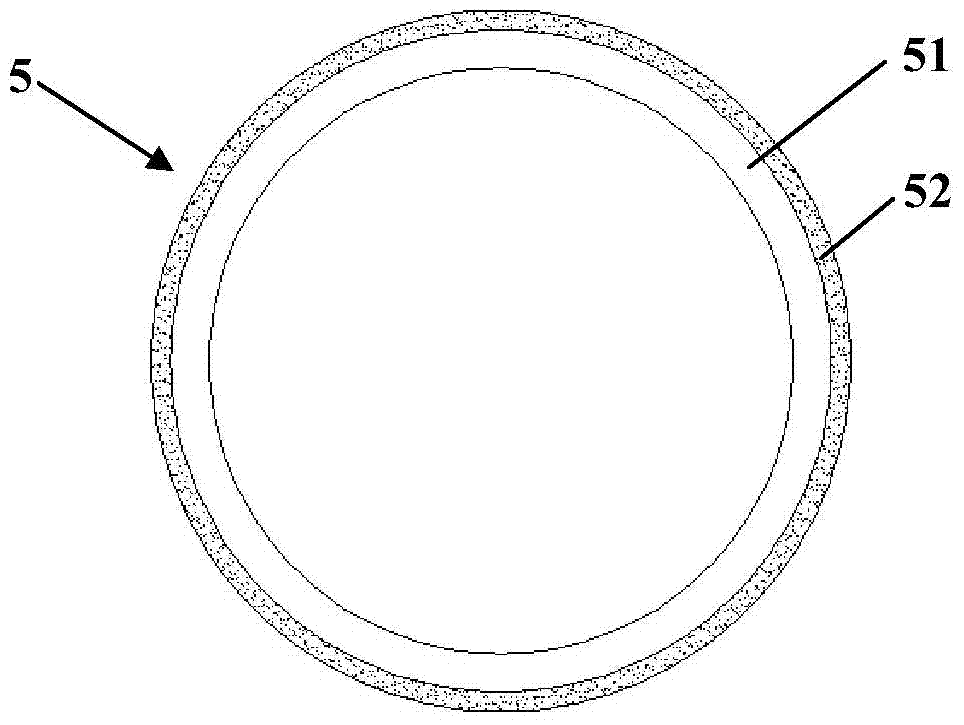

Digital transmission flexible cable for security signal system

ActiveCN103700434AGuaranteed softnessStrong interference abilityPlastic/resin/waxes insulatorsClimate change adaptationPolyesterTinning

The invention discloses a digital transmission flexible cable for a security signal system, which comprises three shielding line groups, wherein each shielding line group comprises two stranded single lines stranded by seven first tinned copper wires; a single line insulation layer is arranged on the external surface of each stranded single line; the two stranded single lines are wrapped and coated with a second polyester tape; the external surface of the second polyester tape is covered with a line resistance shielding layer; the external surface of the line resistance shielding layer is coated with a line resistance isolation layer; each single line insulation layer consists of an outer single line insulation layer and an inner single line insulation layer; each outer single line insulation layer comprises the following materials: 1-3% of natural color cross-linked polyethylene material and 97-99% of plastic color masterbatch; the line resistance isolation layer comprises synthetic mica paper; and the two sides of the synthetic mica paper are adhered and covered with glass fabric through silicon resin adhesive phases. The flexible cable can eliminate the influence of metal particles in the color masterbatch distributed around a conductor on an electric field, so that the transmission attenuation of the cable is reduced; mechanical and physical properties and light and heat ageing resistance of the insulation layers are improved; and performance indices of a product are increased.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

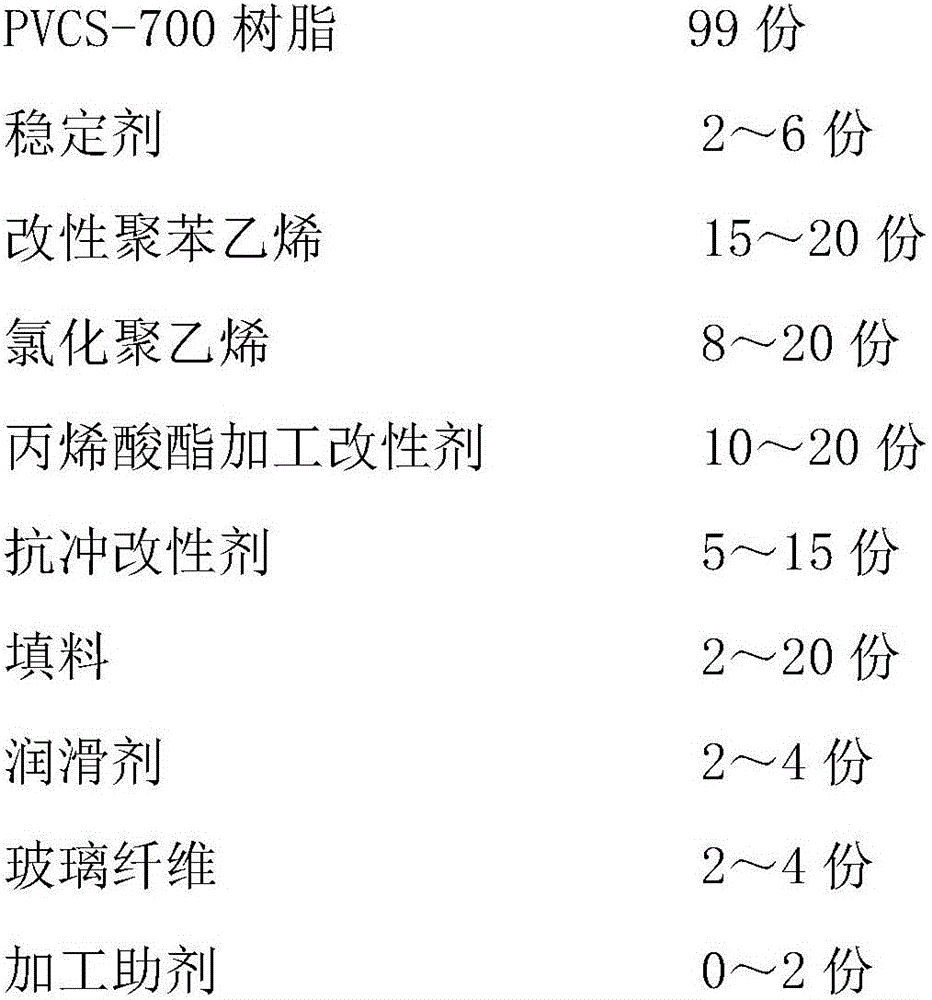

Fireproof door and window composite frame plate material and synthesis method thereof

InactiveCN110014494AGuaranteed uniformityWith flame retardant propertiesDomestic articlesFlat articlesGlass fiberAdhesive

The invention discloses a fireproof door and window composite frame plate material and a synthesis method thereof, and belongs to the technical field of doors and windows. The fireproof door and window composite frame plate material comprises the following components of, in parts by weight, 35-40 parts of logs, 15-20 parts of felling residues, 10-13 parts of processing residues, 6-9 parts of adhesive, 9-15 parts of core material, 8-14 parts of flame retardant and 12-14 parts of filling materials. According to the fireproof door and window composite frame plate material, the flame retardant canbe placed in the material before frame plates of the door and window are formed, the flame retardant and the filling material are fused, the uniformity of the flame retardant is ensured in the pavingprocess, the frame plates are matched with pre-pressing and hot pressing, so that the paving boards have the flame-retardant property, the glass fiber is increased, so that the flame retardancy and the connecting strength are improved, the door and window forming material is high in fusion performance and excellent in overall flame retardancy, the material does not depend on an external coating,and is durable in flame retardancy and free of loss.

Owner:安徽百祺瑞建材科技有限公司

Preparation of polymer composite gelling agent for grouting and application method thereof

The invention belongs to the technical field of a gelling agent for geologic hazard control as well as filling control of goaf and waste laneway or collapse craters after exploitation of other mines, and provides a formula and a method of a novel polymer composite gelling agent for grouting. The gelling agent comprises the following components in percentage by weight: 10-25% of bentonite, 5-20% of cellulose, 5-20% of vegetable gum, 10-15% of calcium hydroxide, 10-25% of inorganic hygroscopic agent, 0.5-1.5% of inorganic dispersant, 0.5-2% of inorganic flocculent, 6-18% of organic flocculent, and 5-15% of alkali metal carbonate. The gelling agent is used for processing and crushing, mixing with water, and injecting to slurry for gelling. According to the invention, the characteristics of high-hydroscopicity mineral matters and hydroscopic synthetic resin are sufficiently absorbed and utilized, and various ion groups are introduced and adjusted to obtain specific performance, so that the gelling agent has strong water solubility, can form hydrophile and water-insoluble gel in the slurry, and has excellent adhesion force to solids and dissolved matters in the slurry, good gelling property, strong water control function, high and adjustable jelling speed, low cost and no pollution.

Owner:JICHANG XIANDAO ENG MATERIAL

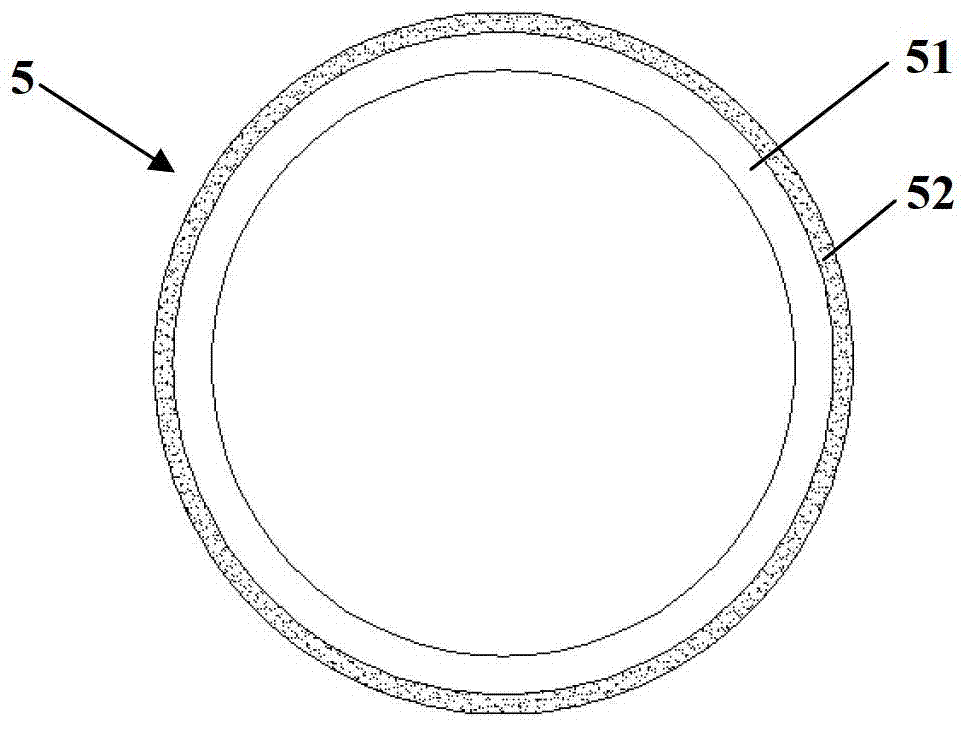

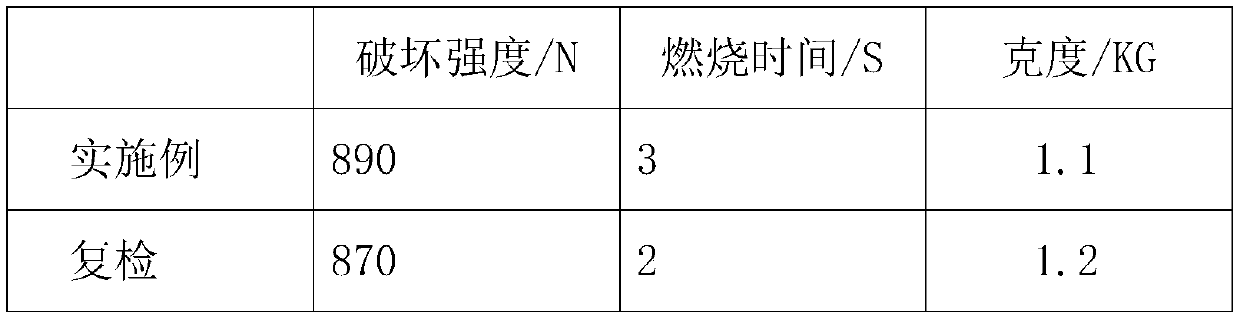

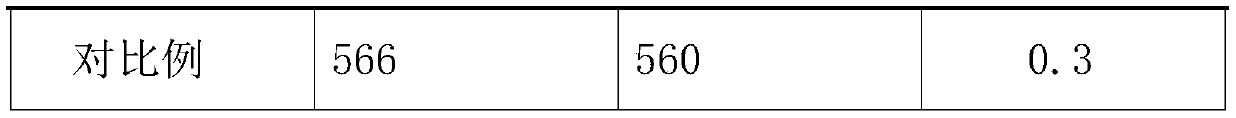

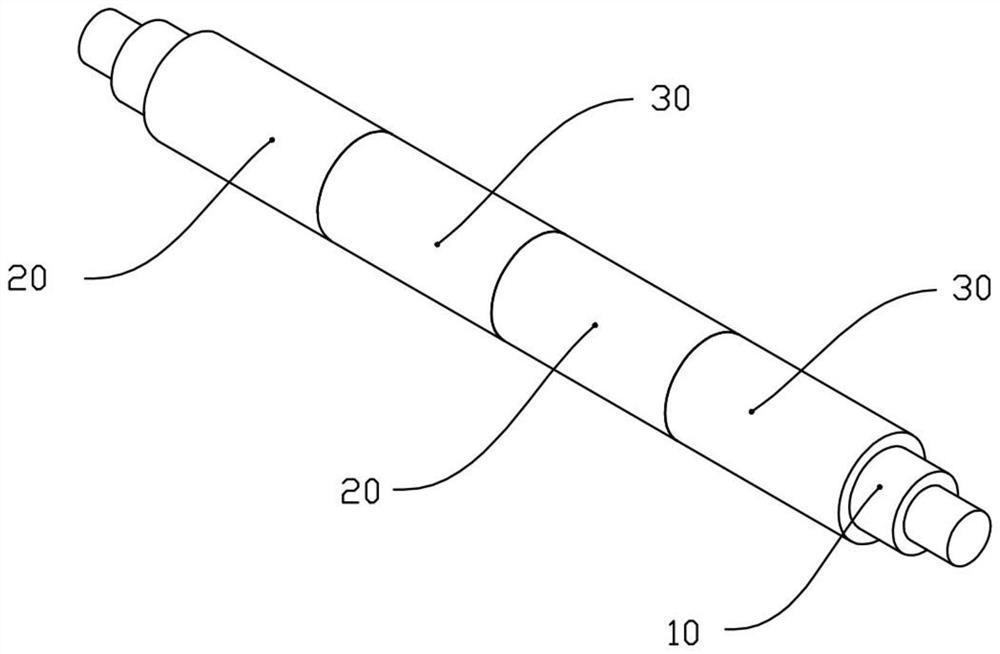

High-flame-retardant and high-temperature-resistant cable and processing method thereof

InactiveCN113488293AWith flame retardant propertiesInsulated cablesCable/conductor manufactureEngineeringInjection molding machine

The invention relates to cable processing, in particular to a high-flame-retardant and high-temperature-resistant cable and a processing method thereof.The processing method of the high-flame-retardant and high-temperature-resistant cable comprises the following steps: 1, a cable core penetrates through two injection molding mechanisms in a high-flame-retardant and high-temperature-resistant cable processing device; 2, the two injection molding mechanisms respectively perform injection molding on different injection molding objects on the cable core; and 3, the two injection molding mechanisms carry out segmented injection molding on the cable core to form the high-flame-retardant and high-temperature-resistant cable. The high-flame-retardant and high-temperature-resistant cable comprises the cable core, coating rubber I and coating rubber II, the coating rubber I and the coating rubber II coat the cable core, and raw materials of the coating rubber I and the coating rubber II are different. One section of the coating rubber I and one section of the coating rubber II are flame-retardant rubber, so that separation is formed on the cable, and the cable has the flame-retardant characteristic.

Owner:吕英男

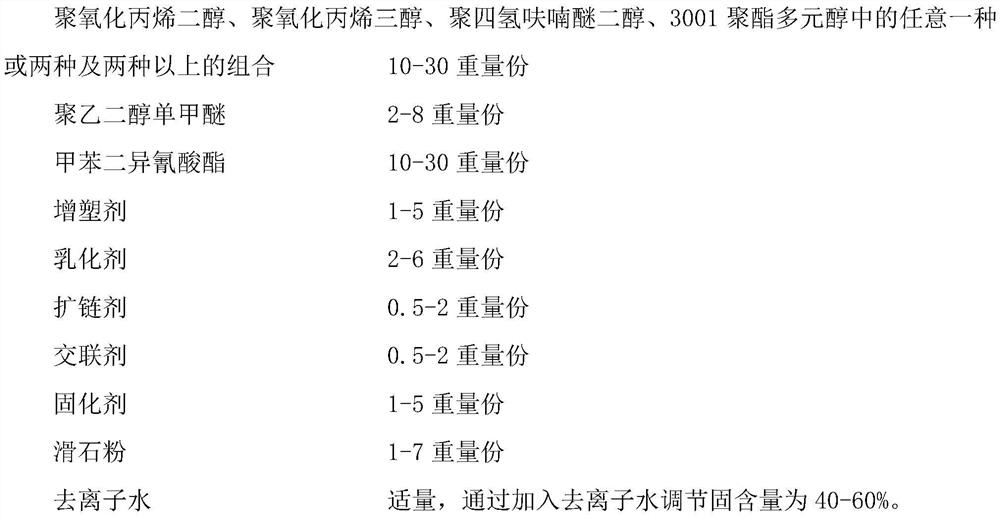

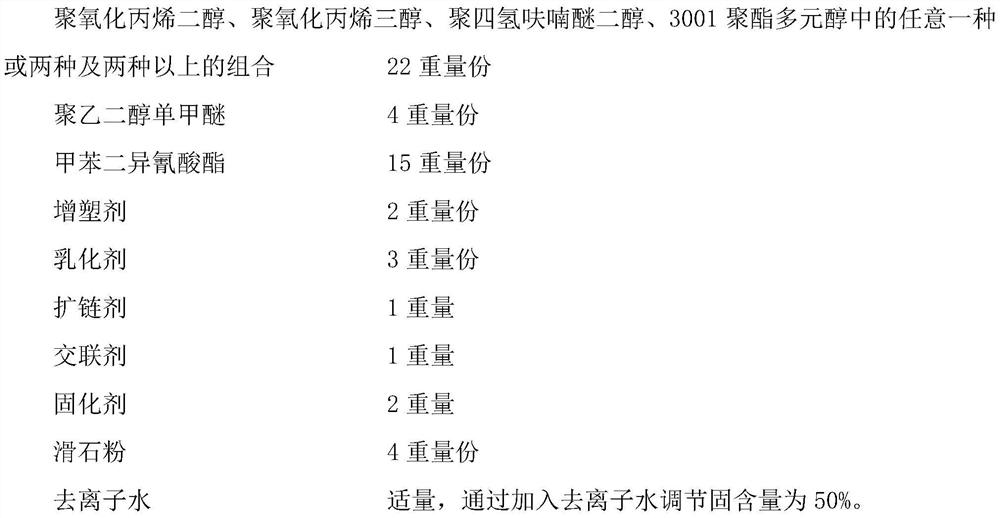

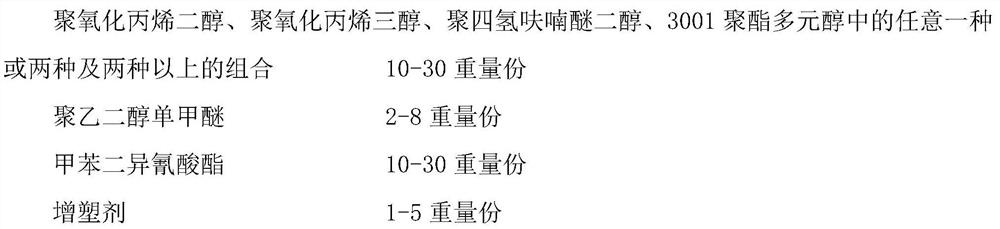

Reusable waterborne polyurethane shielding material and preparation method thereof

PendingCN112250818AReduce wasteGood adhesionFireproof paintsPolyurea/polyurethane coatingsPolyesterPolymer science

The invention relates to a reusable waterborne polyurethane shielding material and a preparation method thereof. The preparation method of the material comprises the steps that: 1, any one or a combination of two or more of polypropylene oxide glycol, polypropylene oxide triol, polytetrahydrofuran ether diol and 3001 polyester polyol, and a plasticizer, are weighed and placed in a reactor filled with nitrogen, stirring the materials at the temperature of 75-95 DEG C and reacting for 15-30 minutes; (2) adding toluene diisocynate, an emulsifier and a curing agent into the reactor, adjusting thewater bath temperature to 80-95 DEG C, and stirring for 30-50 minutes; (3) adding polyethylene glycol monomethyl ether, continuously reacting for 1-2h, dropwise adding a cross-linking agent and a chain extender, adding deionized water to adjust the solid content to 40-60%, continuously reacting for 1-2h, and performing cooling; and (4) adding talcum powder into the raw materials obtained in the step S3, and performing uniform stirring to obtain the waterborne polyurethane shielding material. The material is waterborne polyurethane, can realize good bonding and shielding effects, and has the advantages of high viscosity, reusability, simplicity in operation, no pollution in after-treatment and the like.

Owner:长春一汽富维东阳汽车塑料零部件有限公司

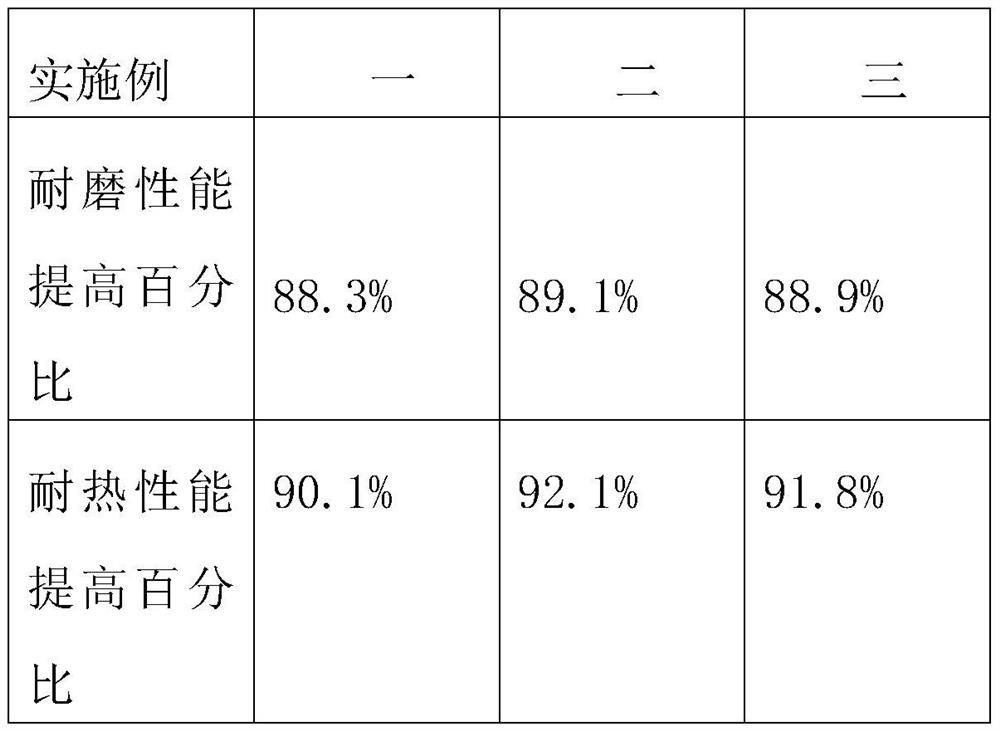

Wear-resistant tire tread formula

InactiveCN113045808AImprove wear resistanceImprove tear resistanceSpecial tyresImideAluminium hydroxide

The invention belongs to the field of tires, particularly relates to a wear-resistant tire tread formula, and provides the following scheme aiming at the problems of poor wear resistance and heat resistance of an existing tire tread: the wear-resistant tire tread formula comprises the following raw materials in parts by weight: 40-60 parts of rubber, 1-5 parts of an anti-aging agent, 10-15 parts of carbon black, 5-10 parts of sulfur, 10-15 parts of nano-zinc oxide, 1-5 parts of stearic acid, 1-5 parts of magnesium hydroxide, 1-5 parts of aluminum hydroxide, 3-8 parts of n-phenylmaleimide, 5-10 parts of calcium stearate and 1-5 parts of phenyl silicone oil. The wear-resistant tire tread formula has good wear resistance and high temperature resistance, and the preparation method is simple.

Owner:山东新豪克轮胎有限公司

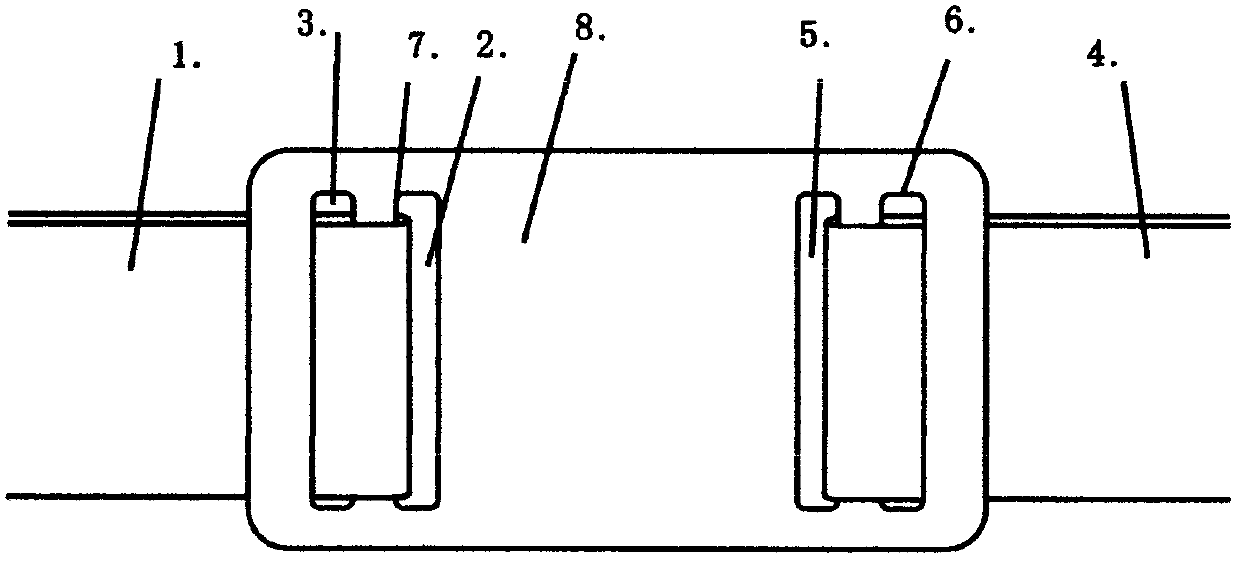

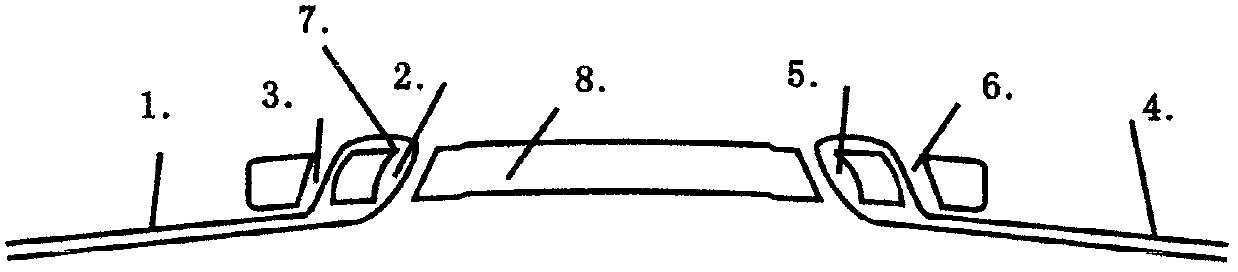

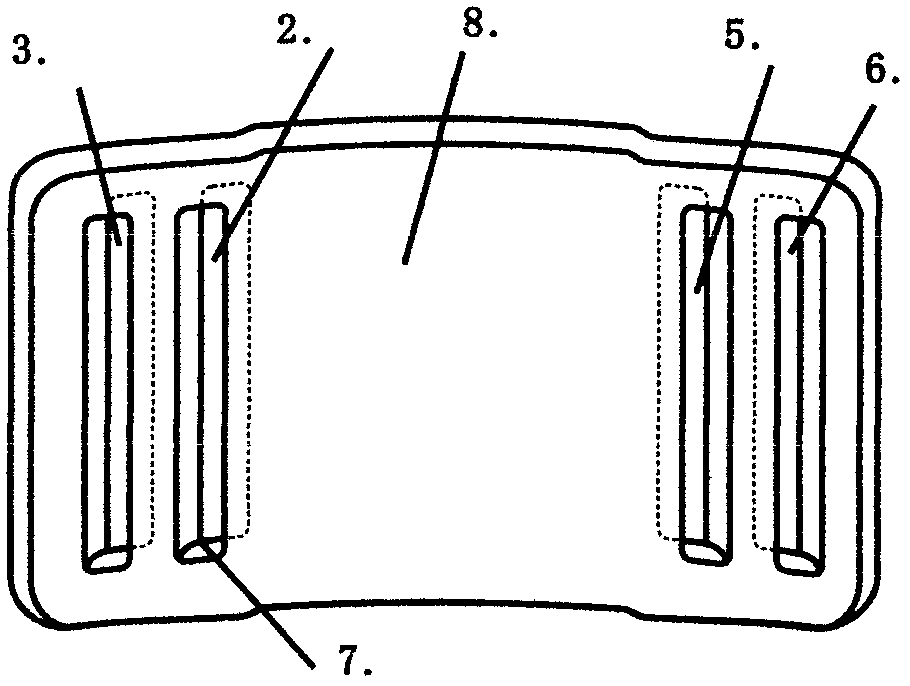

Fire protection waistband

InactiveCN109966670AEasy to put on and take offImprove reliabilitySafety beltsFire protectionEngineering

The invention relates to a fire protection waistband. The fire protection waistband comprises a left end waistband fabric tape, a waistband head, a left lock-up hole, a left storage fixing hole, a right end waistband fabric tape, a right lock-up hole and a right storage fixing hole. The waistband fabric tape with the appropriate length is selected according to a waistline of a wearer, the waistband fabric tape is combined with the waistband metal head before wearing, one end of the left end waistband fabric tape penetrates through the left lock-up hole from inside to outside, and then penetrates through the left storage fixing hole from outside to inside (the right end waistband fabric tape penetrates through the right lock-up hole and the right storage fixing hole), that is to say, combination is completed; and in the wearing process, the right end waistband fabric tape penetrates through the right lock-up hole from inside to outside and then the required tightness degree is adjusted,and penetrates through the right storage fixing hole from outside to inside, that is to say, wearing is completed. Compared with the prior art, the fire protection waistband is convenient and rapid to wear and take off, and can be worn or taken off on the left side and the right side according to a habit of a user, the reliability and the tensile strength are high, the weight is light, the size is small, the fire protection waistband has the flame-retardant characteristic, and the wearing requirement during fire protection training and fire extinguishment rescuing is sufficiently met.

Owner:南京际华五三零二服饰装具有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com