ATF oil resistant flame retardant type impregnated resin as well as preparation method and application thereof

A resin-impregnated, flame-retardant technology, applied in the field of insulating materials, can solve the problems that cannot meet the development needs of oil-cooled electric vehicle motors, reduce the heat resistance and mechanical strength of the impregnated resin, poor ATF oil resistance, etc., and achieve easy promotion Application, human health friendliness, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

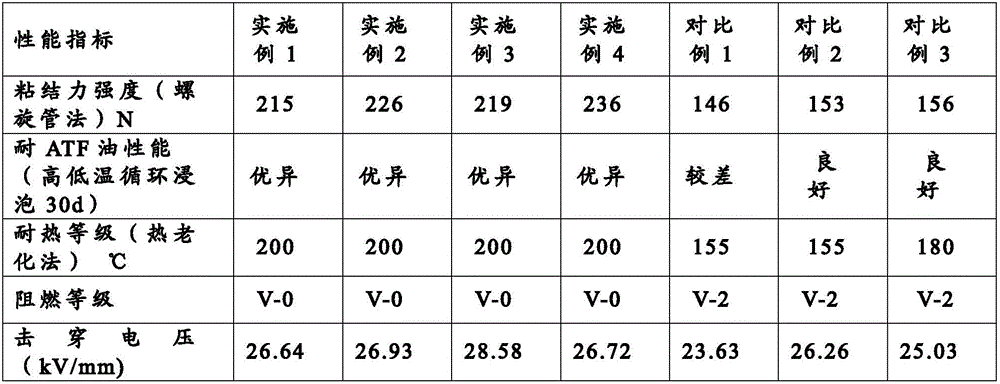

Examples

Embodiment 1

[0041] This embodiment provides an ATF oil-resistant flame-retardant impregnating resin, which is prepared by the following steps:

[0042] (1) Add 500g of Dow431 epoxy resin, 36g of acrylic acid, 0.13g of chromium acetylacetonate, and 0.56g of hydroquinone into the reaction flask, heat to 135°C for 1.5h; cool down to 110-120°C, add 20g of cis Butenedioic anhydride was reacted at 140°C for 1 hour, vacuumed, the acid value was 6 mgKOH / g, and the temperature was lowered to obtain a modified epoxy resin.

[0043] (2) Add 880g of diphenyldihydroxysilane, 918g of γ-methacryloxypropyltrimethoxysilane and 1.7g of stannous chloride into the reaction flask, heat to 148°C, react for 4 hours, and then vacuumize , cooling to obtain silicone resin.

[0044] (3) Add 60g of benzoxazine resin to the reaction bottle, set up a reflux device, heat to 190°C in an oil bath, and after the benzoxazine resin is melted, add 23g of toluene, stir evenly to form benzoxazine Oxazine toluene solution. W...

Embodiment 2

[0047] This embodiment provides an ATF oil-resistant flame-retardant impregnating resin, which is prepared by the following steps:

[0048] (1) Add 800.9g F51 epoxy resin, 43.5g acrylic acid, 0.26g chromium acetylacetonate, and 0.86g hydroquinone into the reaction flask, heat to 140°C for 2 hours; cool down to 115°C, add 14.8g cis Butenedioic anhydride was heated to 145°C and reacted for 1 hour, vacuumed, the acid value was 7.5mgKOH / g, and the temperature was lowered to obtain a modified epoxy resin.

[0049] (2) Add 500g of diphenyldihydroxysilane, 430g of vinyltriethoxysilane and 0.95g of stannous chloride into the reaction flask, heat to 150°C, react for 5 hours, vacuumize, and cool down to obtain silicone resin .

[0050](3) Add 85g of benzoxazine resin to the reaction bottle, set up a reflux device, heat to 185°C in an oil bath, and after the benzoxazine resin is melted, add 30g of toluene, stir evenly to form benzoxazine Oxazine toluene solution. When the temperature ...

Embodiment 3

[0053] This embodiment provides an ATF oil-resistant flame-retardant impregnating resin, which is prepared by the following steps:

[0054] (1) Add 835g Dow431 epoxy resin, 65.3g acrylic acid, 0.28g chromium acetylacetonate, and 0.92g hydroquinone to the reaction flask, heat to 146°C and react for 1.5h; cool down to 120°C, add 25g cis-butyl Alkenic acid anhydride was heated to 145°C for 1 hour, vacuumed, the acid value was 7 mgKOH / g, and the temperature was lowered to obtain a modified epoxy resin.

[0055] (2) Add 650g of diphenyldihydroxysilane, 445g of vinyltrimethoxysilane and 1.1g of stannous chloride into the reaction flask, heat to 145°C, react for 3 hours, vacuumize, and cool down to obtain silicone resin .

[0056] (3) Add 105g of benzoxazine resin to the reaction bottle, set up a reflux device, heat it to 185°C in an oil bath, and after the benzoxazine resin is melted, add 40g of toluene, stir evenly to form benzoxazine Oxazine toluene solution. When the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com