High-flame-retardant and high-temperature-resistant cable and processing method thereof

A processing method and high temperature resistant technology, applied in the direction of insulated cables, cable/conductor manufacturing, cables, etc., can solve the problems of complex process, insufficient structural strength, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

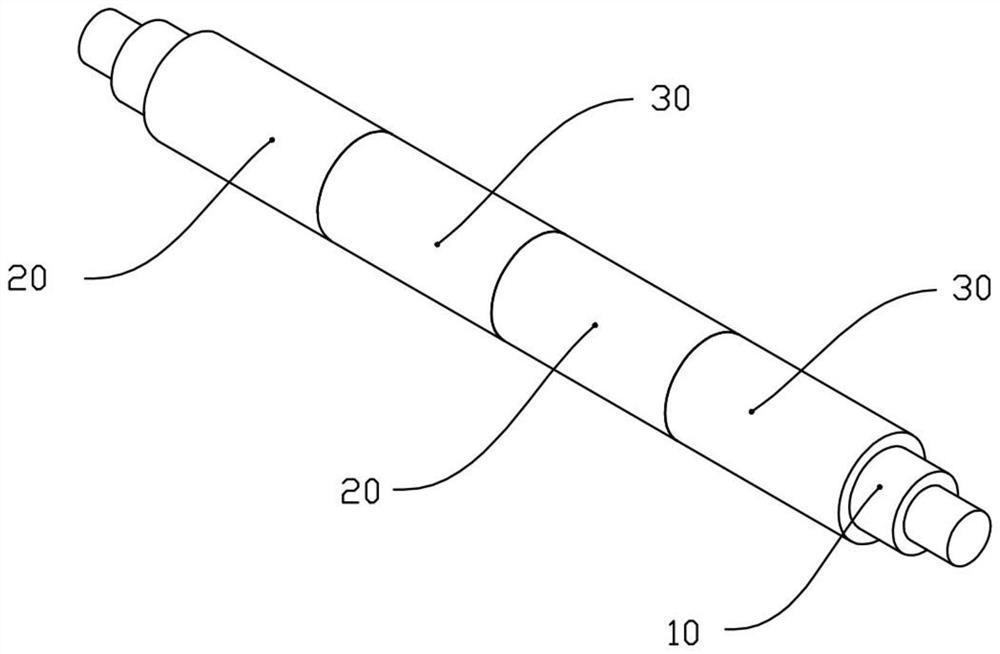

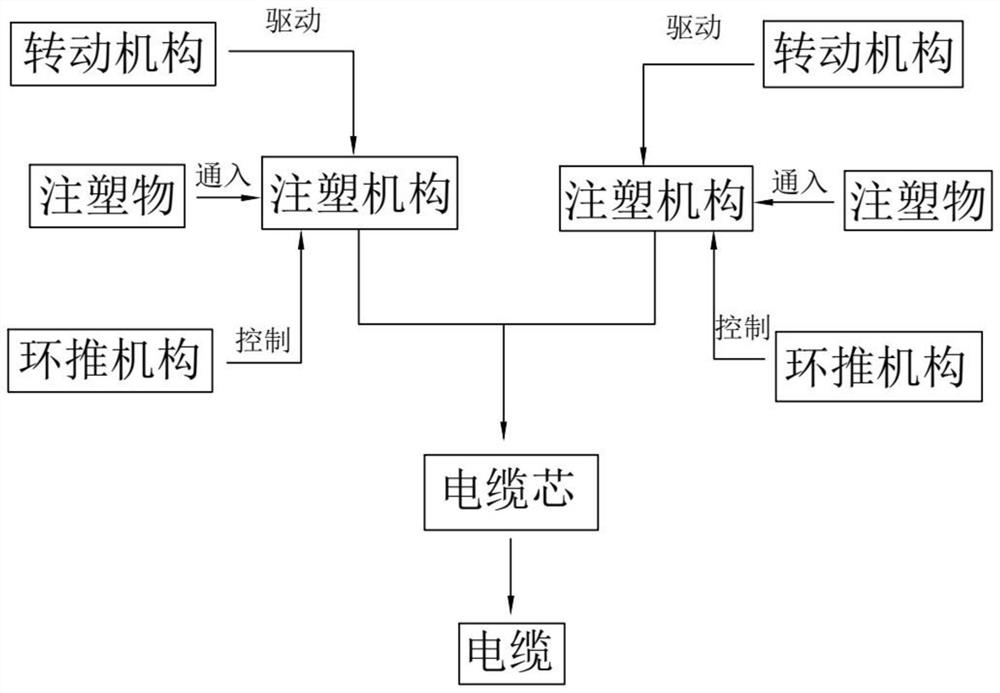

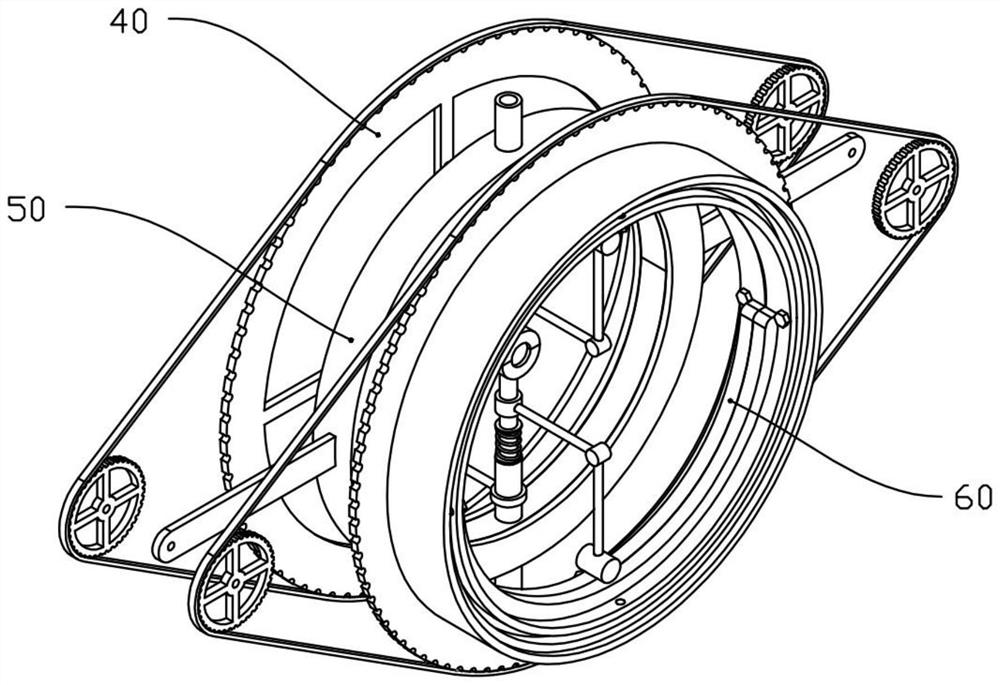

[0035] Combine below Figures 1 to 15 Describe this embodiment, a high flame-retardant and high-temperature-resistant cable processing device, including a rotating mechanism 40, an injection molding mechanism 50, a ring pushing mechanism 60, a beam-shaped cylinder 70, a feeding mechanism 80, and a device bracket 90. The device bracket 90 includes a support ring 91, support bracket 92 and connecting column 93, two supporting rings 91 are provided with, the outside of two supporting rings 91 is all fixedly connected with supporting bracket 92, is fixedly connected with connecting column 93 between two supporting rings 91, connecting column 93 The middle part is fixedly connected with beam-shaped tube 70;

[0036] Further, a heating mechanism is arranged on the beam-shaping cylinder 70, and then the beam-shaping cylinder 70 ensures the temperature of the coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com