Fire protection waistband

A belt and fire-fighting technology, which is applied in the field of clothing, can solve the problems of low reliability and tensile strength, large belt buckle size, and uncomfortable wearing, and achieve the effect of convenient putting on and taking off, small size, and meeting wearing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

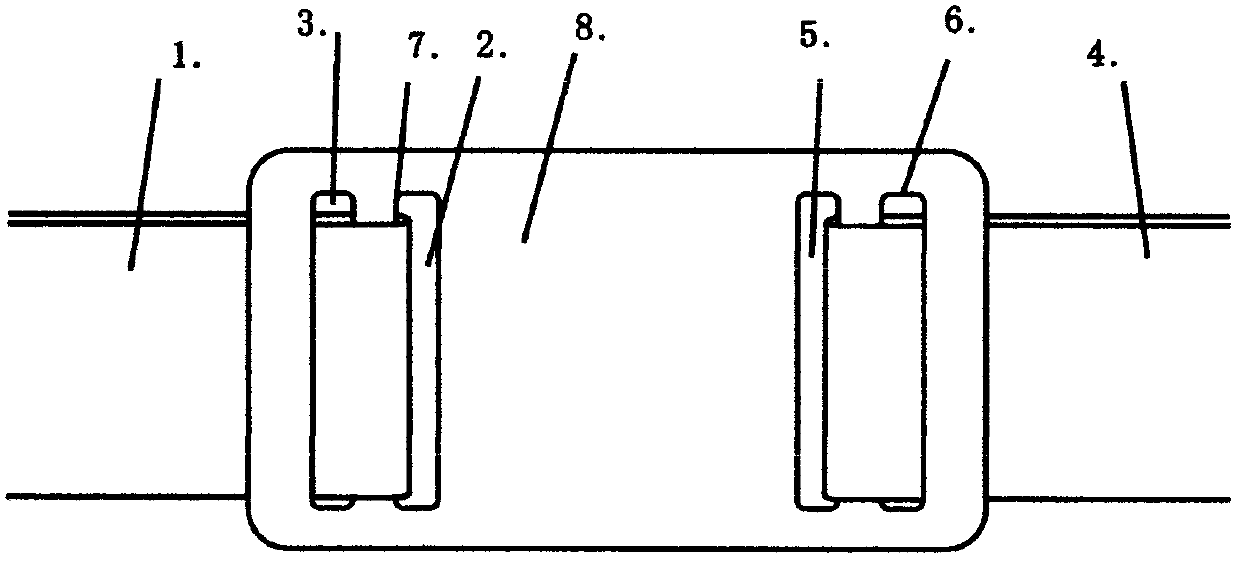

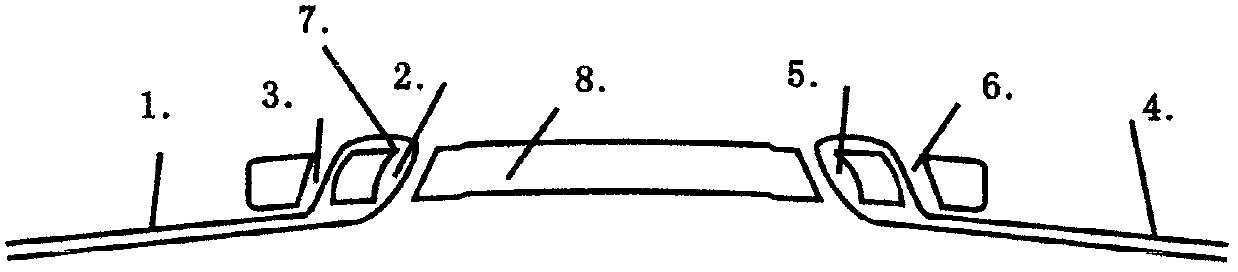

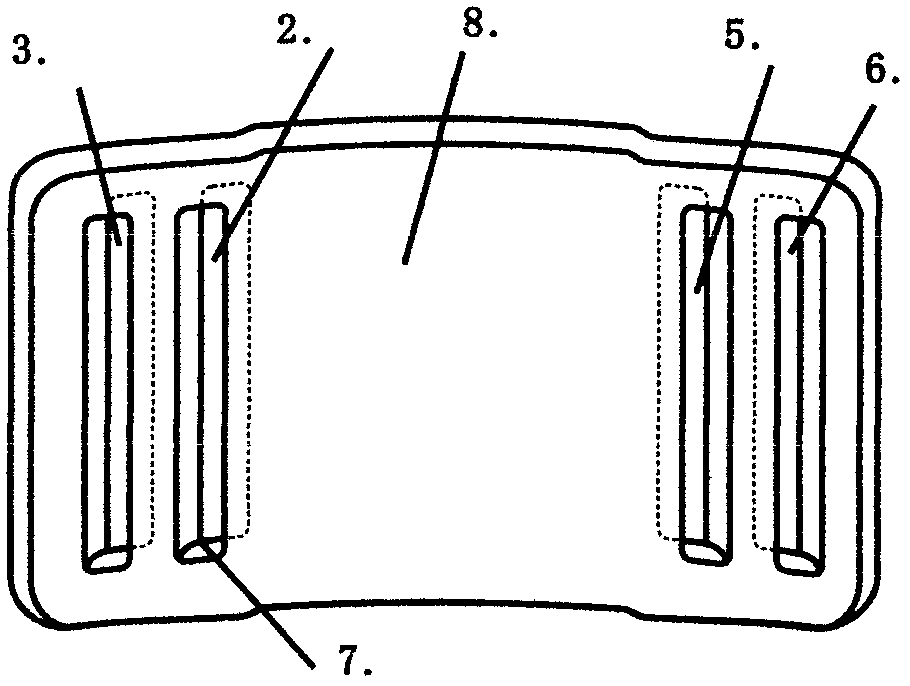

[0015] A fire-fighting belt, the left end belt webbing 1, the belt head 8, the left locking hole 2, the left storage fixing hole 3, the right belt webbing 4, the right locking hole 5, the right storage fixing hole 6, and the locking part 7.

[0016] Choose a webbing belt of an appropriate length according to the waist circumference of the wearer. Before wearing, combine the webbing belt 1 at the left end with the belt head 8. Pass the webbing belt 1 at the left end through the left locking hole 2 from the inside to the outside, and then pass through the left storage fixing hole from the outside to the inside. 3 (you can also pass the right webbing belt 4 through the right locking hole 5 and the right storage fixing hole 6) to complete the combination; when wearing, pass the right webbing webbing 4 from the inside to the outside through the right locking hole 5 and then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com