Fireproof door and window composite frame plate material and synthesis method thereof

A synthesis method and technology of composite frame, applied in the field of doors and windows, can solve the problems of reduced flame retardant effect, difficult processing, peeling, etc., and achieve the improvement of flame retardancy and connection strength, excellent overall flame retardancy, and lasting flame retardancy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

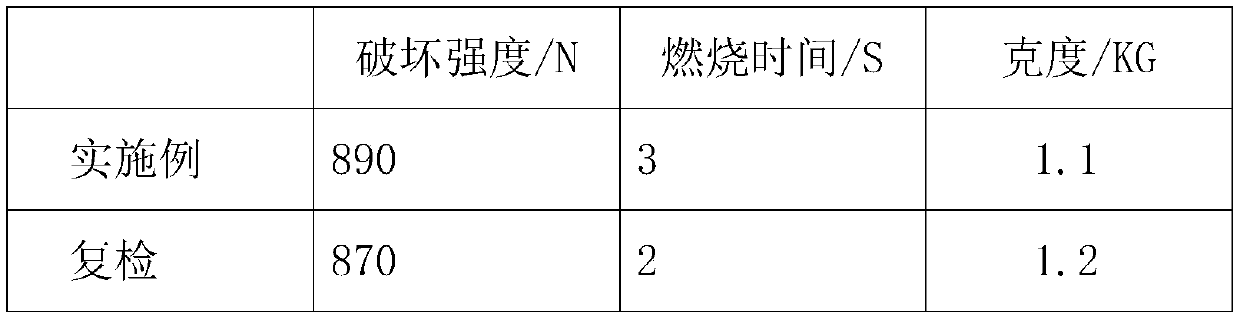

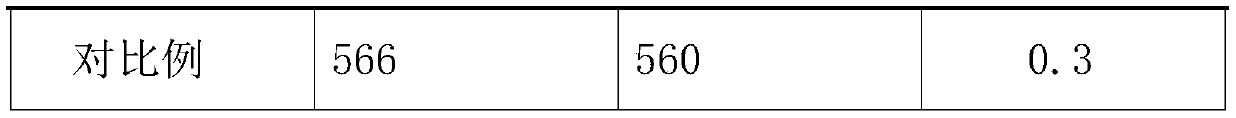

Examples

Embodiment

[0051] Step 1: Selection of raw materials: 37 parts of logs, 17 parts of felling residues, 11 parts of processing residues, and 7 parts of adhesives were weighed in order, and the materials were weighed. First, the logs were cut into short fibers, and the raw materials were added first. If the specific gravity is small, the specific gravity is added later, the adhesive is added last, and the log short fiber is added in batches;

[0052] Step 2: Log sawing and cooking: Control the sawing length of the log to 17mm, and the waste generated by the log, such as small wood segments, cut ends and sawdust, needs to be recycled. The loss rate is 7%, and it is combined with high-temperature cooking. Put in the disinfectant according to the ratio of 3:0.5, the cooking time is 30min, and the temperature is 100°C;

[0053] Step 3: Preparation of shavings: the shaving slenderness ratio is flaky shavings S=L / t, and rod-shaped shavings S=L / d, wherein L is the length of the shavings, d is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com