Environment-friendly type low-smoke flame-retardant insulated rubber composition, preparation method, use and product applying composition

A low-smoke, flame-retardant and insulating rubber technology, applied in the field of artificial rubber, can solve the problems of small insulation resistance and unsuitability, and achieve the effects of low cost, flame-retardant characteristics, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

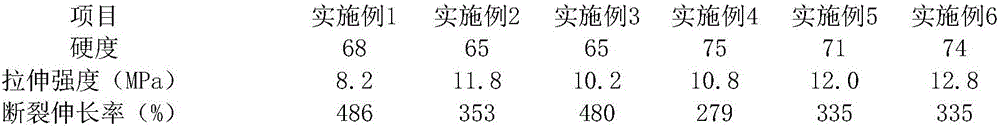

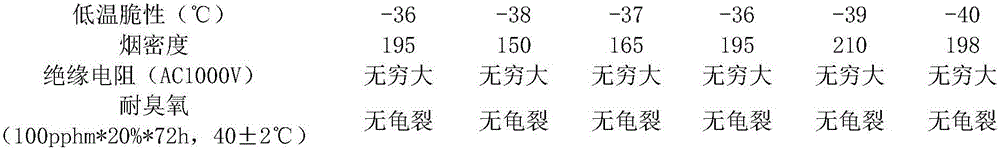

Examples

Embodiment 1

[0032] The invention discloses an environment-friendly low-smoke flame-retardant insulating rubber composition, and its components are prepared according to the following parts by weight:

[0033] 100 parts of EPDM rubber, 10 parts of carbon black N550, 30 parts of precipitated silica, 90 parts of flame retardant 100F, 30 parts of paraffin oil, 2 parts of anti-aging agent RD, 1 part of anti-aging agent MB, 5 parts of zinc oxide , 1.5 parts of stearic acid, 1.5 parts of sulfur S, 2 parts of accelerator TMTD, and 1 part of accelerator CZ.

[0034] Further, the EPDM rubber is a brand with high Mooney and high ethylene content.

[0035] Preferably, the ethylene-propylene-diene rubber has an ethylene content of 50-80%.

[0036] Further, the present invention also discloses a preparation method of an environment-friendly low-smoke flame-retardant insulating rubber composition, comprising the following steps:

[0037] 1. Take the EPDM rubber, anti-aging agent RD, anti-aging agent M...

Embodiment 2

[0044] The invention discloses an environment-friendly low-smoke flame-retardant insulating rubber composition, and its components are prepared according to the following parts by weight:

[0045] 100 parts of EPDM rubber, 40 parts of carbon black N550, 40 parts of flame retardant 100E, 100 parts of flame retardant 06B, 30 parts of paraffin oil, 1.5 parts of antioxidant RD, 1.5 parts of antioxidant MB, 7 parts of zinc oxide, 2 parts of stearic acid, 0.5 parts of sulfur S, 2 parts of accelerator TMTD, and 1 part of accelerator CZ.

[0046] Further, the EPDM rubber is a brand with high Mooney and high ethylene content.

[0047] Preferably, the ethylene-propylene-diene rubber has an ethylene content of 50-80%.

[0048] Further, the present invention also discloses a preparation method of an environment-friendly low-smoke flame-retardant insulating rubber composition, comprising the following steps:

[0049] 1. Take the EPDM rubber, anti-aging agent RD, anti-aging agent MB, zinc...

Embodiment 3

[0056] The invention discloses an environment-friendly low-smoke flame-retardant insulating rubber composition, and its components are prepared according to the following parts by weight:

[0057] 100 parts of EPDM rubber, 10 parts of carbon black N550, 40 parts of flame retardant F2, 160 parts of flame retardant 06B, 30 parts of paraffin oil, 2 parts of anti-aging agent RD, 1 part of anti-aging agent MB, 5 parts of zinc oxide, 1 part of stearic acid, 3 parts of peroxide DCP, and 2 parts of TAIC.

[0058] Further, the EPDM rubber is a brand with high Mooney and high ethylene content.

[0059] Preferably, the ethylene-propylene-diene rubber has an ethylene content of 50-80%.

[0060] Further, the present invention also discloses a preparation method of an environment-friendly low-smoke flame-retardant insulating rubber composition, comprising the following steps:

[0061] 1. Take the EPDM rubber, anti-aging agent RD, anti-aging agent MB, zinc oxide and stearic acid in the formu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com