Reinforced flame-retardant low-warpage PBT alloy material and preparation method thereof

An alloy material and low warpage technology are applied in the field of reinforced flame retardant and low warpage PBT alloy materials and their preparation, which can solve the problems that the products do not have flame retardant properties and the difficulty of crystalline polymer PBT, and achieve good mechanical properties, The effect of improving glass fiber orientation and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

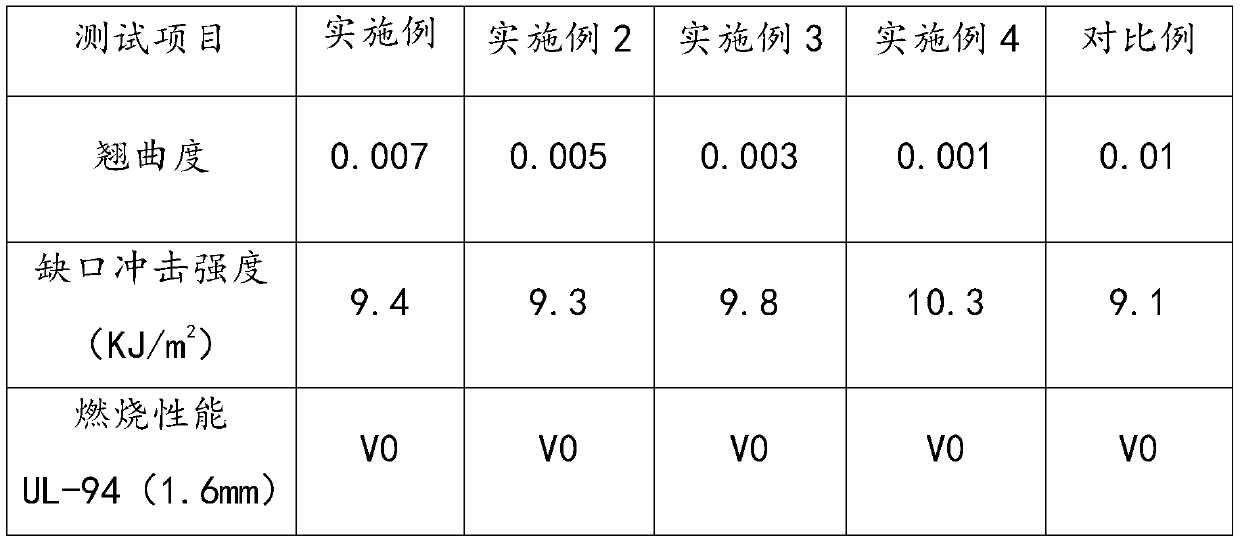

Examples

preparation example Construction

[0034] The present invention also includes a method for preparing an enhanced flame-retardant low-warpage PBT alloy material, comprising the following steps:

[0035] Step 1, pass polybutylene terephthalate, polycarbonate, inorganic filler, compound flame retardant, toughening agent, compound antioxidant, lubricant, transesterification inhibitor and anti-dripping agent through The high-speed mixer mixes evenly at high speed to obtain mixed materials;

[0036] Step 2: Add the mixed material to the main feed port of the twin-screw extruder, and the glass fiber to the side feed port of the twin-screw extruder, melt, extrude, cool, dry, and cut into pellets.

[0037] The temperature of each section of the barrel of the twin-screw extruder is set at 210-250° C., and the screw speed is 350 rpm.

Embodiment 1

[0040] (1) Weigh each component by weight: PBT: 44 parts, PC: 7 parts, ordinary alkali-free glass fiber: 22 parts, calcium carbonate: 10 parts, brominated epoxy: 8.5 parts, antimony trioxide: 2 parts, ethylene-methyl acrylate copolymer: 6 parts, antioxidant 1010: 0.1 part, antioxidant 168: 0.1 part, lubricant PETS (pentaerythritol stearate): 0.2 part, triphenyl phosphite: 0.1 part, 0.1 part of polytetrafluoroethylene;

[0041] (2) After the raw materials other than glass fiber are mixed evenly in the high mixer, the glass fiber is fed from the side feeding port, and melted and extruded through the extruder. The extrusion temperature is 210-250°C, and the screw speed is 350rpm. Then cool, dry, and cut into pellets to get the product.

Embodiment 2

[0043] (1) Weigh each component by weight: PBT: 44 parts, PC: 7 parts, ordinary alkali-free glass fiber: 22 parts, kaolin: 10 parts, brominated epoxy: 8.5 parts, antimony trioxide: 2 Parts, ethylene-methyl acrylate copolymer: 6 parts, antioxidant 1010: 0.1 part, antioxidant 168: 0.1 part, lubricant PETS: 0.2 part, triphenyl phosphite: 0.1 part, polytetrafluoroethylene 0.1 part share;

[0044] (2) After mixing the raw materials other than glass fiber evenly in the high mixer, the glass fiber is fed from the side feeding port, and melted and extruded through the extruder. The extrusion temperature is 210-240 ° C, and the screw speed is 350 rpm. Then cool, dry, and cut into pellets to get the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com