Heat-conducting pouring sealant and preparation method thereof

A heat-conducting potting and triglycidyl technology, applied in the field of resin, can solve the problems of reduced resin occupancy, reduced cohesion and bond strength, etc., and achieves the effect of saving addition, improving thermal conductivity and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A thermally conductive potting compound of the present invention, comprising A component and B component,

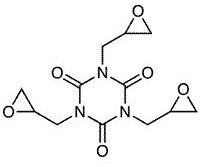

[0043] The composition of component A is 30wt% 1,3,5-triglycidyl isocyanurate (TGIC), 70wt% thermally conductive filler. The thermal conductive filler is 30-50 μm aluminum nitride: 10-20 μm zinc oxide: 200nm silicon carbide = 70%: 15%: 15%.

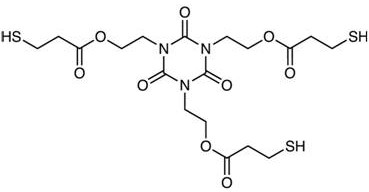

[0044] The composition of component B is 96wt% 3-mercaptopropionic acid-[2,4,6-trioxo-1,3,5-triazine-1,3,5(2H,4H,6H)-idene] Tris-2,1-ethylene glycol ester (CAS: 36196-44-8), 1wt% Additol VXW6208-60, 1wt% Dow Corning FS-80, 2wt% BYK306.

[0045] The preparation method of heat conduction potting glue of the present invention comprises the following steps:

[0046] (1) Preparation of component A: Mix 30-50 μm aluminum nitride: 10-20 μm zinc oxide: 200 nm silicon carbide at a mass ratio of 70%︰15%︰15% to obtain a thermally conductive filler. After mixing TGIC and heat-conducting filler through an airflow mixer, component A can...

Embodiment 2

[0050] A heat-conducting potting compound of the present invention includes A component and B component.

[0051] The composition of component A is 30wt% 1,3,5-triglycidyl isocyanurate (TGIC), 70wt% thermally conductive filler. The thermal conductive filler is 30-50μm aluminum nitride: 10-20μm zinc oxide: 200nm silicon carbide = 70%: 15%: 15%.

[0052] The composition of component B is 96wt% 1,3,5-tris(2-hydroxyethyl) isocyanurate (CAS No.: 839-90-7), 1wt% Additol VXW6208-60, 1wt% Dow Corning FS-80, 2wt% BYK306.

[0053] The preparation method of heat conduction potting glue of the present invention comprises the following steps:

[0054] (1) Prepare component A: Mix 30-50 μm aluminum nitride: 10-20 μm zinc oxide: 200 nm silicon carbide at a mass ratio of 70%: 15%: 15% to obtain a thermally conductive filler. After mixing TGIC and heat-conducting filler through an airflow mixer, component A can be obtained. The condition is that the charge volume coefficient is 0.6, and com...

Embodiment 4

[0081] According to the method of Example 1, different thermally conductive fillers were designed, and the influence of different thermally conductive fillers on the thermal conductivity of the flame-retardant potting compound was investigated.

[0082] Thermally conductive filler 1: 1-3μm zinc oxide

[0083] Thermally conductive filler 2: 30-50μm aluminum nitride

[0084] Thermally conductive filler 3: 10-20μm zinc oxide

[0085] Thermally conductive filler 4: 5-10μm magnesium oxide

[0086] Thermally conductive filler 5: 1-3μm silicon carbide

[0087] Thermally conductive filler 6: 30-50μm aluminum nitride: 10-20μm zinc oxide: 1-3μm silicon carbide=60%: 25%: 15%

[0088] Thermally conductive filler 7: 30-50μm aluminum nitride: 10-20μm zinc oxide: 200nm silicon carbide = 70%: 15%: 15%.

[0089] Thermally conductive filler 8: 30-50μm aluminum nitride: 10-20μm zinc oxide: 30nm silicon carbide = 55%: 25%: 20%.

[0090] The influence of the conductive filler on the performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com