Preparation method of solid-liquid phase change type TPU electrolyte

An electrolyte and reaction vessel technology, applied in the field of TPU, can solve problems such as poor interface charge transfer, loss, and accidental accidents, achieve excellent safety and conductivity, prevent battery burning, and avoid deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

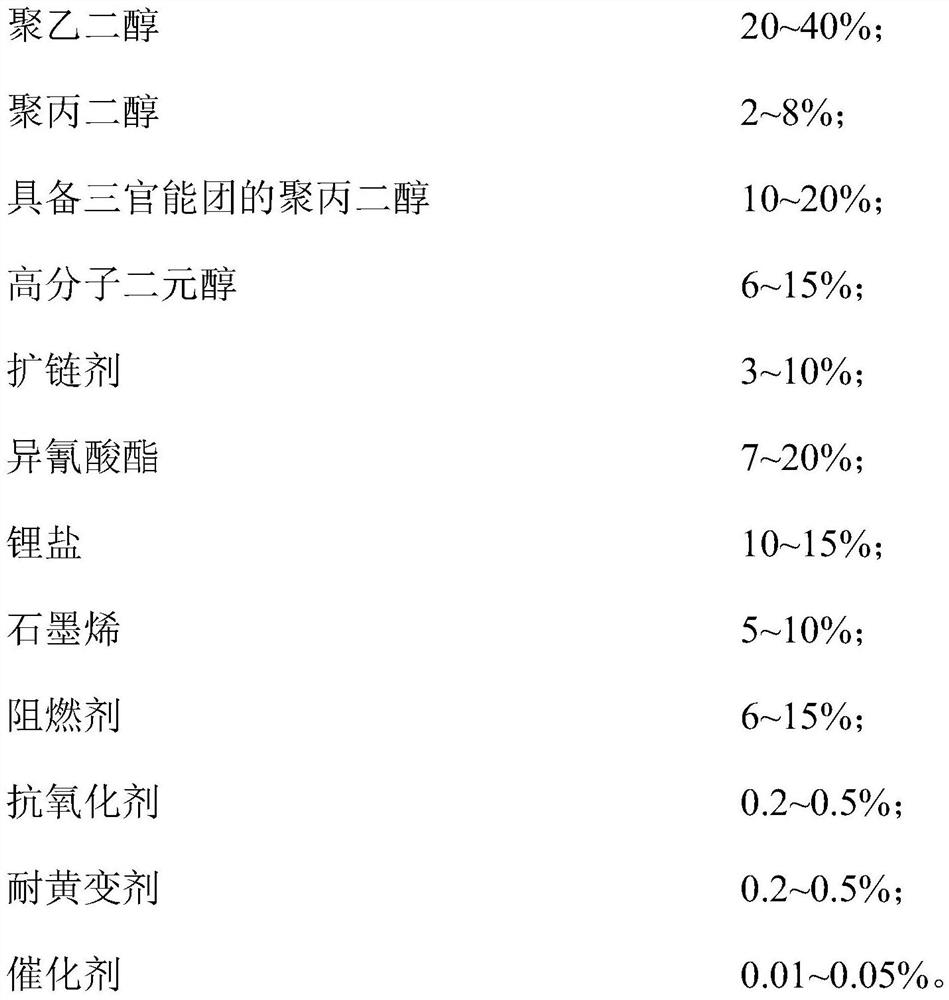

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a solid-liquid phase-change type TPU electrolyte, the preparation method comprising:

[0037] In the first stage, special polymer diols are made:

[0038] Step 1. Put the monomer diols into the reaction vessel and raise the temperature to 55-65°C;

[0039] Step 2, put adipic acid into the reaction vessel, heat up to 75-85°C and continue stirring;

[0040] Step 3. Continue stirring after heating up to 100-110°C;

[0041] Step 4. Vacuumize the reaction vessel and raise the temperature to 130-190°C until the acid value of the material is lower than 30mgKOH / g, then raise the temperature to 205-215°C;

[0042] Step 5. Add tetrabutyl titanate, heat up to 223-227°C and continue stirring until the acid value of the material is lower than 1mgKOH / g, then heat up to 235-245°C;

[0043] Step 6, reducing the vacuum degree of the reaction vessel (that is, increasing the internal pressure) until the output value of the monomer glycols r...

Embodiment 1

[0073] This embodiment provides a method for preparing a solid-liquid phase-change type TPU electrolyte, the preparation method comprising:

[0074] In the first stage, special polymer diols are made:

[0075] Prepare ingredients by weight as follows:

[0076] 1,3 butanediol 2.00kg;

[0077] Adipic acid 2.92kg;

[0078] Tetrabutyl titanate 0.01kg;

[0079] Step 1. Put 1,3-butanediol into the reaction vessel and raise the temperature to 60°C;

[0080] Step 2, put adipic acid into the reaction vessel, heat up to 80°C and continue stirring for 2 hours;

[0081] Step 3, after heating up to 105°C, continue stirring for 2 hours;

[0082] Step 4. Vacuumize the reaction vessel with a pressure of 600mmHg, heat up to 140°C and maintain for 1 hour, then heat up to 160°C and maintain for 1 hour, then heat up to 180°C and maintain for 3 hours until the acid value of the material is lower than 30mgKOH / g After that, the temperature was raised to 210°C;

[0083] Step 5. Add tetrabutyl ...

Embodiment 2

[0095] This embodiment provides a method for preparing a solid-liquid phase-change type TPU electrolyte, the preparation method comprising:

[0096] In the first stage, special polymer diols are made:

[0097] Prepare ingredients by weight as follows:

[0098] 1,3 Butanediol 1.985kg;

[0099] Adipic acid 2.29kg;

[0100] Tetrabutyl titanate 0.01kg;

[0101] Step 1. Put 1,3-butanediol into the reaction vessel and raise the temperature to 60°C;

[0102] Step 2, put adipic acid into the reaction vessel, heat up to 80°C and continue stirring for 2 hours;

[0103] Step 3, after heating up to 105°C, continue stirring for 2 hours;

[0104] Step 4. Vacuumize the reaction vessel with a pressure of 600mmHg, heat up to 140°C and maintain for 1 hour, then heat up to 160°C and maintain for 1 hour, then heat up to 180°C and maintain for 3 hours until the acid value of the material is lower than 30mgKOH / g After that, the temperature was raised to 210°C;

[0105] Step 5. Add tetrabutyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com