Viscosity-reducing flame-retardant type non-cured rubber asphalt waterproof coating and preparation method thereof

A kind of asphalt waterproof coating and non-curing rubber technology, which is applied in the direction of asphalt coating, other rubber coatings, fireproof coatings, etc., can solve the problems of no flame retardancy, easy fire, and difficult construction, so as to facilitate dissolution and avoid Effect of fire and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

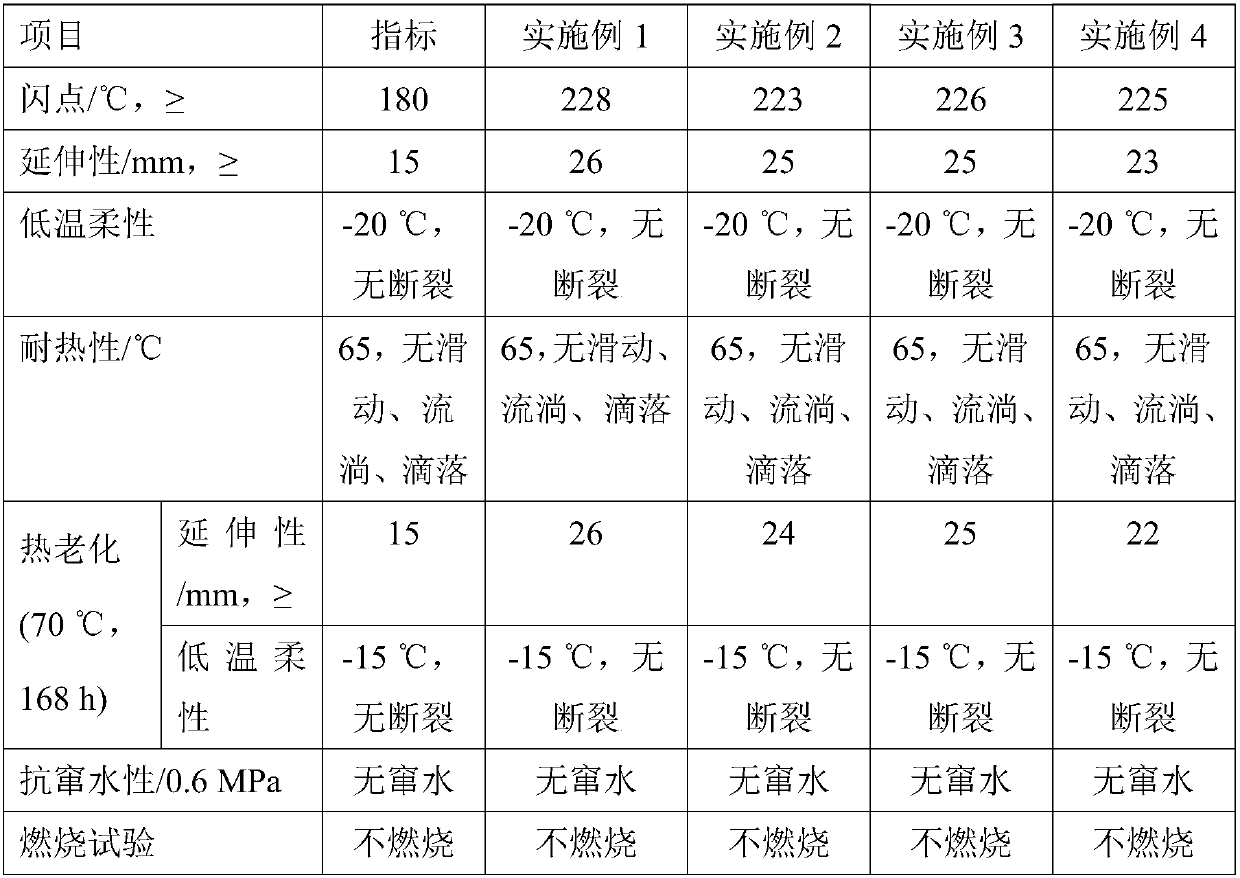

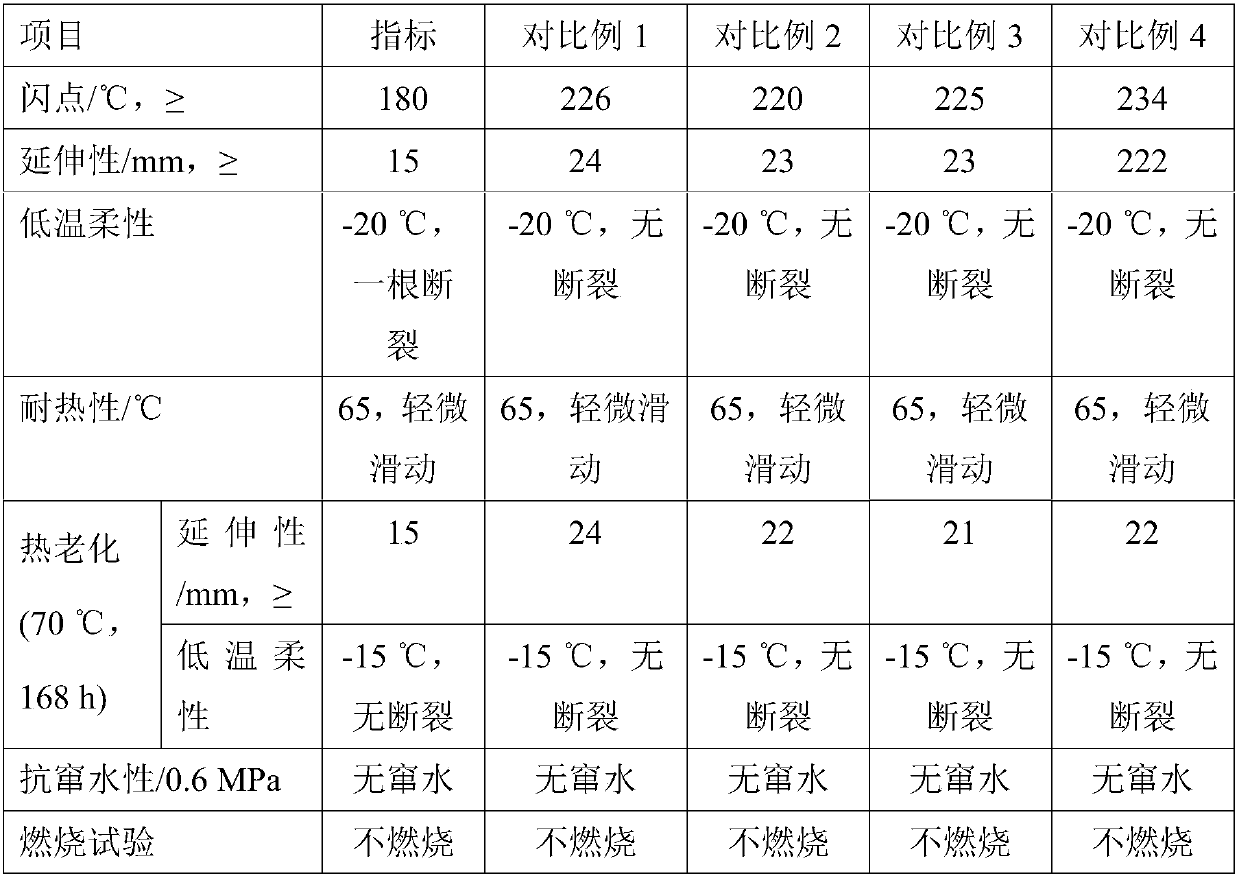

Examples

Embodiment 1

[0026] A viscosity-reducing flame-retardant non-curing rubber asphalt waterproof coating, comprising the following components in parts by weight: 70 parts of 70# road petroleum asphalt, 10 parts of catalytic cracking oil slurry, 10 parts of SBS 1301, 20 parts of terpene resin, 20 parts of 80 mesh waste rubber powder, 25 parts of fly ash, 2 parts of ethylene bisstearamide, 10 parts of antimony oxide.

[0027] The preparation method is:

[0028] (1) Weigh each component by parts by weight, mix modifier and softener, heat to 140°C, and stir at a speed of 2000r / min for 30min;

[0029] (2) Add petroleum pitch to the mixture of step (1), heat to 170°C, and stir for 30min at a speed of 2000r / min;

[0030] (3) Add tackifier, waste rubber powder, filler and flame retardant to the mixture in step (2) in sequence, maintain the temperature at 170°C, and stir at a speed of 5000r / min for 50min;

[0031] (4) Cool down to 150° C., add a flow enhancer to the mixture in step (3), stir for 20 ...

Embodiment 2

[0033] A viscosity-reducing flame-retardant non-curing rubber asphalt waterproof coating, comprising the following components in parts by weight: 30 parts of 110# road petroleum asphalt, 20 parts of catalytic cracking oil slurry, 7 parts of SBS 4303, and 12 parts of coumarone resin , 10 parts of 60 mesh waste rubber powder, 15 parts of talcum powder, 6 parts of ethylene bis stearamide, 6 parts of (2-ethylhexyl)-diphenyl phosphate.

[0034] The preparation method is:

[0035] (1) Weigh each component by parts by weight, mix the modifier and the softener, heat to 120°C, and stir at a speed of 2000r / min for 20min;

[0036] (2) Add petroleum pitch to the mixture of step (1), heat to 160°C, and stir for 30min at a speed of 2000r / min;

[0037] (3) Add tackifier, waste rubber powder, filler and flame retardant to the mixture in the step (2) in sequence, maintain the temperature at 160°C, and stir at a speed of 5000r / min for 60min;

[0038] (4) Cool down to 140° C., add a flow enhan...

Embodiment 3

[0040] A viscosity-reducing flame-retardant non-curing rubber asphalt waterproof coating, comprising the following components in parts by weight: 50 parts of 90# road petroleum asphalt, 10 parts of naphthenic oil, 6 parts of SBS 1301, 5 parts of C5 petroleum resin, 5 parts of 100 mesh waste rubber powder, 15 parts of fly ash, 3 parts of ethylene bis stearamide, 3 parts of tributyl phosphate, 6 parts of red phosphorus.

[0041] The preparation method is:

[0042] (1) Weigh each component by parts by weight, mix modifier and softener, heat to 150°C, and stir at a speed of 2000r / min for 30min;

[0043] (2) Add petroleum pitch to the mixture of step (1), heat to 180°C, and stir for 20min at a speed of 2000r / min;

[0044] (3) Add tackifier, waste rubber powder, filler and flame retardant to the mixture in the step (2) in sequence, maintain the temperature at 180°C, and stir at a speed of 5000r / min for 30min;

[0045] (4) Cool down to 160° C., add a flow enhancer to the mixture in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com