Machine-made sand C120 ultra-high-strength concrete easily pumped to super high-rise

A technology of ultra-high-strength concrete and machine-made sand, applied in the field of building materials and concrete, can solve the problems of shortage of natural sand resources, limited application scope, rough surface morphology, etc., and achieve the effect of improving poor gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

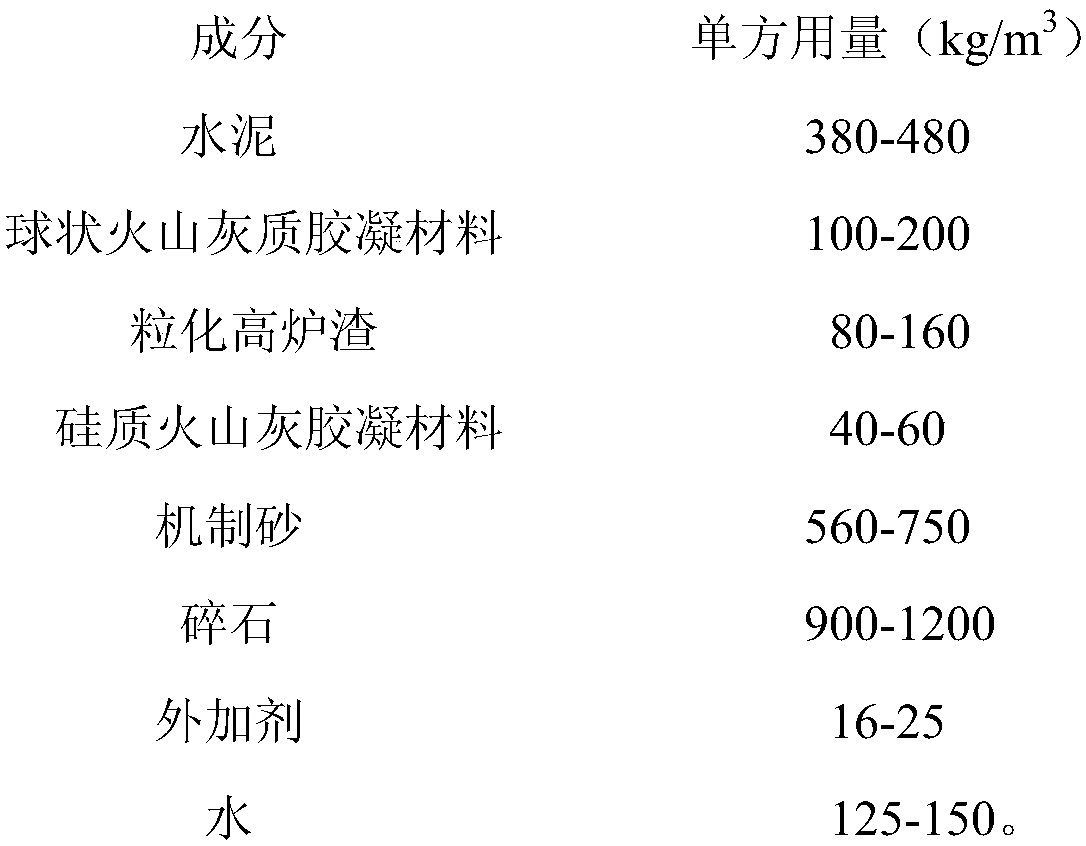

[0022] A machine-made sand C120 ultra-high-strength concrete that is easy to pump in super-high-rise buildings. The dosage ratio and performance of the concrete are as follows:

[0023]

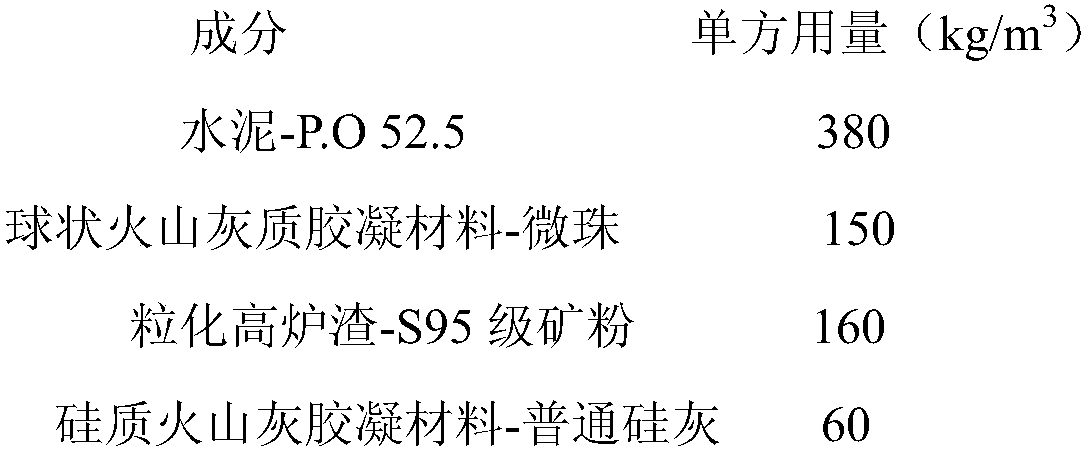

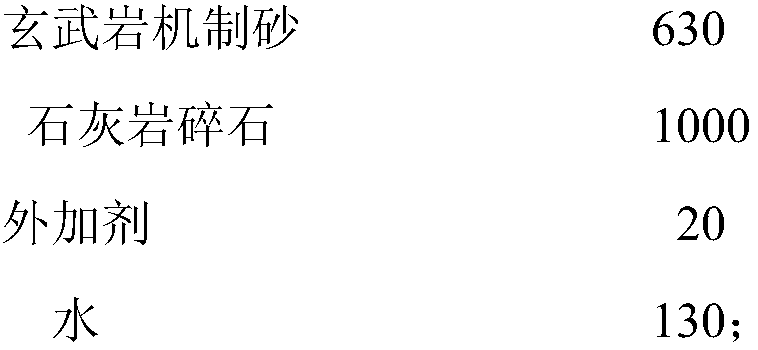

[0024]

[0025] The machine-made sand is basalt machine-made sand with a fineness modulus of 2.8, a bottom powder content of 4%, and an MB value of 0.8. The MB value is the sub-blue value, which indicates the mud content in the machine-made sand. The gravel is limestone with a particle size of 5-20mm and a mud content of 1.1%. The admixture is a viscosity-reducing polycarboxylic acid composite admixture with a water reducing rate of 35%.

[0026] Preparation method: adopt the conventional concrete preparation method, put limestone gravel and basalt machine-made sand into the concrete mixer, add half of the water for wet mixing for 30-40 seconds, then put cement and mineral admixtures into the mixing pot, and wet mix for 30-40 seconds 40s, and finally dissolve the admixture in the rema...

Embodiment 2

[0029] A machine-made sand C120 ultra-high-strength concrete that is easy to pump in super-high-rise buildings. The dosage ratio and performance of the concrete are as follows:

[0030]

[0031] The machine-made sand is limestone machine-made sand with a fineness modulus of 2.9, a bottom powder content of 3%, and an MB value of 1.0. The MB value is the sub-blue value, which indicates the mud content in the machine-made sand. The crushed stone is limestone crushed stone with a particle size of 5-20mm and a mud content of 0.8%. The admixture is a viscosity-reducing polycarboxylic acid composite admixture with a water reducing rate of 35%.

[0032] Preparation method: adopt the conventional concrete preparation method, put limestone gravel and limestone machine-made sand into the concrete mixer, add half of the water and mix for 30-40s, then put cement and mineral admixtures into the mixing pot, wet mix for 30- 40s, and finally dissolve the admixture in the remaining half of...

Embodiment 3

[0035] A machine-made sand C120 ultra-high-strength concrete that is easy to pump in super-high-rise buildings. The dosage ratio and performance of the concrete are as follows:

[0036]

[0037] The machine-made sand is limestone machine-made sand with a fineness modulus of 3.0, a bottom powder content of 4%, and an MB value of 1.0. The MB value is the sub-blue value, which indicates the mud content in the machine-made sand. The gravel is diabase gravel with a particle size of 5-20mm and a mud content of 1.0%. The admixture is a viscosity-reducing polycarboxylic acid composite admixture with a water reducing rate of 35%.

[0038]Preparation method: adopt the conventional concrete preparation method, put the diabase gravel and limestone machine-made sand into the concrete mixer, add half of the water and mix for 30-40s, then put the cement and mineral admixture into the mixing pot, wet mix 30-40s, and finally dissolve the admixture in the remaining half of the water and ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

| Expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com