Rubble mixed red clay aggregate and preparation method thereof

A technology of laterite granules and preparation methods, which is applied in roads, road repairs, roads, etc., can solve the problems that the CBR value of laterite granules cannot meet the specification requirements, the performance of natural laterite granules varies greatly, and the performance is not completely consistent. Achieve high engineering application value, improve poor grading, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

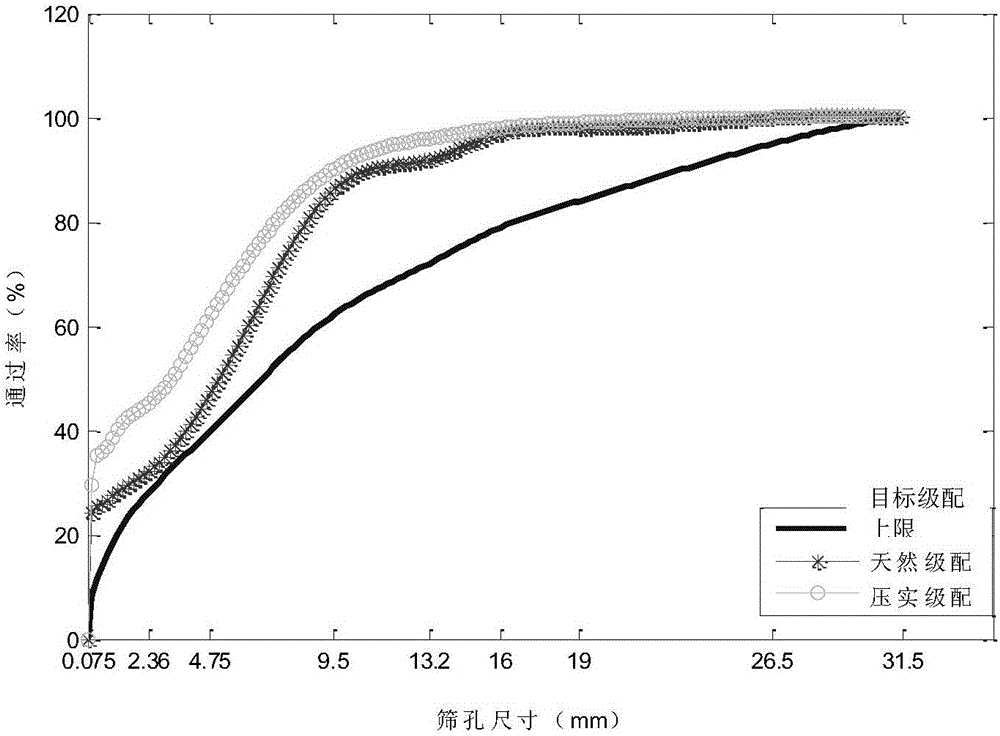

[0053] The laterite aggregates from the Babo road section in Equatorial Guinea and the unscreened crushed stone produced by the rock rolling field were selected as raw materials, and their material properties are shown in Table 1 and Table 2 below, respectively.

[0054] Table 1 Screening results of laterite aggregates in Babo road section

[0055] Mesh size(mm) 31.5 9.5 4.75 2.36 1.18 0.6 0.3 0.15 0.075 Natural Grading Passed (%) 100 87 54 36 33 32 31 29 27 Compaction grading passed (%) 100 93 78 54 42 39 35 31 30

[0056] Table 2 Screening results of unscreened gravel in Babo road section

[0057] Mesh size(mm) 31.5 19 9.5 4.75 2.36 0.6 0.075 Passing rate(%) 100 71.2 37.5 19.1 10.2 4.2 1.2

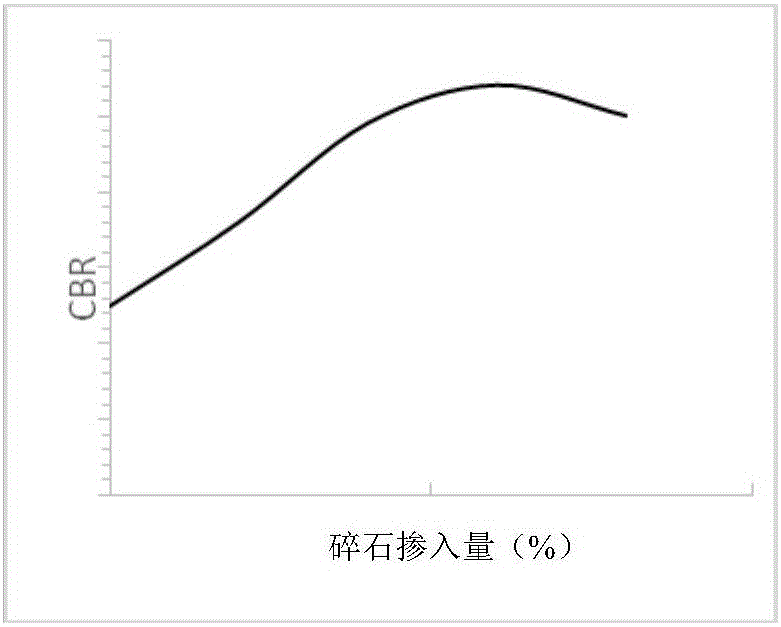

[0058] It can be obtained from the natural gradation and gradation after compaction of natural laterite granules. The mixing amount of the primary crushed stone is selected as 2%, 4%, 6%, and 8%, and the...

Embodiment 2

[0063] The laterite aggregates from the Bindong road section in Equatorial Guinea and the unscreened gravel produced by the rock rolling field were selected as raw materials, and their material properties are shown in Table 3 and Table 4 below, respectively.

[0064] Table 3 Screening results of laterite aggregates in Bindong road section

[0065]

[0066] Table 4 Screening results of unscreened gravel in Bindong road section

[0067]

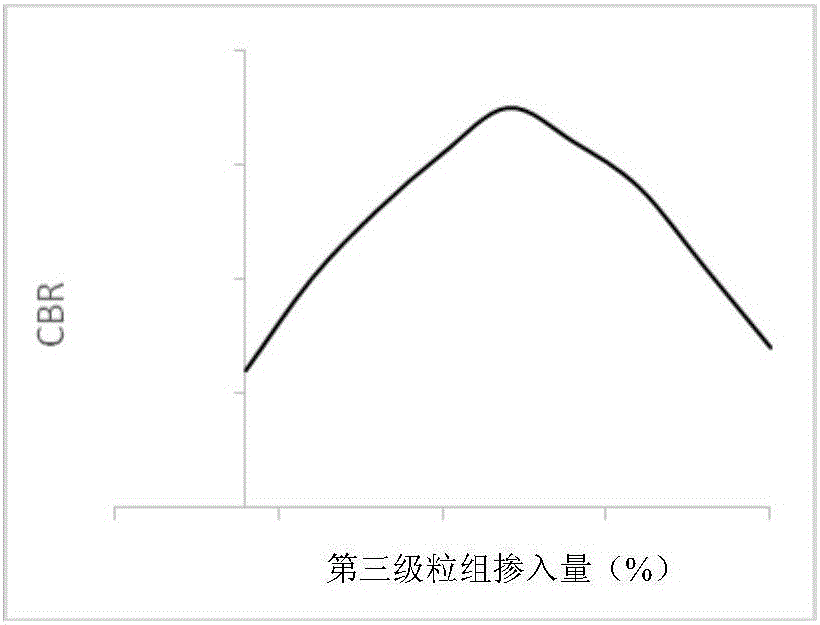

[0068] The natural gradation and gradation after compaction of natural laterite pellets can be obtained. The mixing amount of the primary crushed stone is selected as 2%, 4%, 6%, and 8%, and the primary mixture is prepared by mixing, and 5 groups of test 3 different parallel test pieces were taken for each group of test pieces; after that, the second-level mixture was prepared with the third group of granules, and 5 sets of test pieces were prepared, and 3 different parallel test pieces were taken for each group of test pieces. The resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com