Modular container

a container and module technology, applied in the field of modules, can solve the problems of affecting the appearance of the product, the difficulty of one-piece containers, and the high defective rate of containers during production, and achieve the effect of convenient and convenient processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Before the present invention is described in greater detail, it should foe noted that the seems reference numerals have been used to denote like elements throughout the specification.

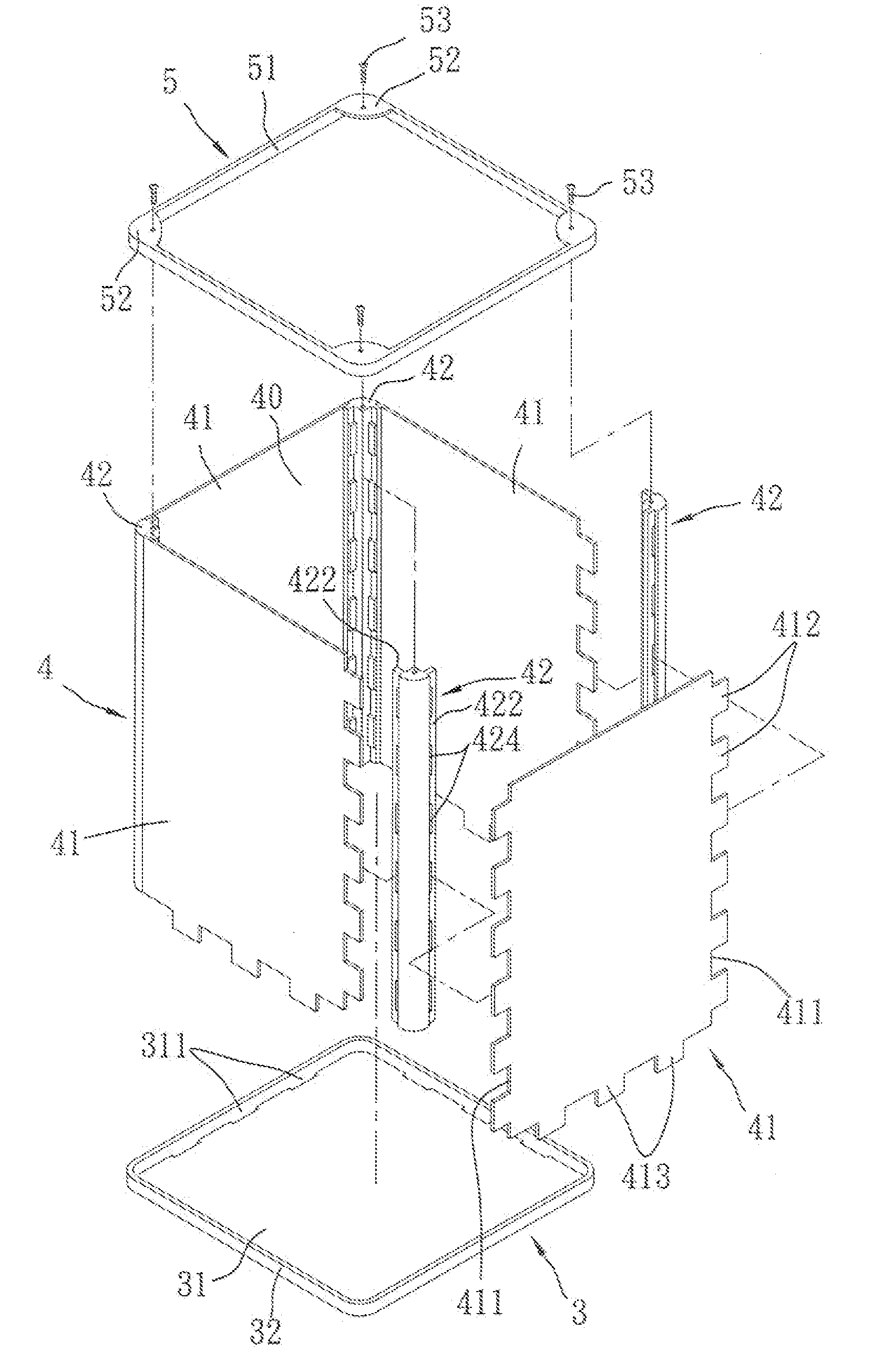

[0020]Referring to FIGS. 3 to 5, the first preferred embodiment of a modular container according to the present invention is shown to comprise a base seat 3, a tubular body 4, and a top frame 5.

[0021]The base seat 3 has a substantially rectangular base wall 31, an upstanding flange 32 extending from a periphery of the base wall 31, and a plurality of spaced-apart bottom insert holes 311 formed in the bass wall 31 adjacent to the upstanding flange 32 and equally spaced apart from each other.

[0022]The tubular body 4 is connected to she base seat 3 with the upstanding flange 32 surrounding a bottom end thereof. The tubular body 4 has a plurality of corners, a plurality of wall plates 41, and a plurality of pillars 42. In this embodiment, the tubular body 4 has four corners, four wall plates 41, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com