Environment-friendly and flame retarded rubber material of inside liner of fire hose and preparation method thereof

A technology for fire hose and inner lining layer, which is applied in the direction of machinery and equipment, hoses, pipes/pipe joints/pipe fittings, etc., can solve the problems of higher price, weather resistance, and difficulty in bonding synthetic fiber fabrics. Achieve the effect of outstanding cost performance and excellent weathering resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Raw material chlorinated polyethylene rubber 30Kg, composite stabilizer TW1.5Kg, magnesium oxide 3Kg, zinc oxide 1.5Kg, carbon black 4.5Kg, white carbon black 6Kg, aluminum hydroxide 24Kg, binder A 1.5Kg and citric acid increase Put 4.5Kg of plasticizer into the internal mixer, mix for 210 seconds, then add 0.9Kg of dicumyl peroxide and 0.6Kg of triallyl isocyanurate and continue mixing for 30 seconds, the mixing temperature is 123°C, After the internal mixing is discharged, it is additionally mixed on the open mill for 300 seconds. The mixing temperature is 105°C. Then it is pressed into a rubber sheet suitable for processing on a double-roll calender. Sample 1 of the rubber material for the inner lining of fire-fighting hoses.

Embodiment 2

[0035] The raw material chlorinated polyethylene rubber 30Kg, composite stabilizer TW 2Kg, magnesium oxide 3Kg, zinc oxide 3Kg, carbon black 4Kg, white carbon black 5.5Kg, aluminum hydroxide 25Kg, binder A 1.5Kg and citric acid plasticizer Put 4Kg into the internal mixer, mix for 240 seconds, then add 1Kg of dicumyl peroxide and 0.7Kg of triallyl isocyanurate and continue mixing for 30 seconds. Afterwards, additionally knead on the open mill for 240 seconds at a kneading temperature of 102°C, then press it on a double-roll calender to form a rubber sheet suitable for processing, and pack it after being cooled by an eight-roll cooler to obtain an environmentally friendly, flame-retardant fire hose Inner liner rubber material sample 2.

Embodiment 3

[0037] The raw material chlorinated polyethylene rubber 30Kg, composite stabilizer TW 3Kg, magnesium oxide 2.5Kg, zinc oxide 2Kg, carbon black 6Kg, white carbon black 5Kg, aluminum hydroxide 24Kg, binder A 1.8Kg and citric acid plasticizer Put 5Kg into the internal mixer, mix for 180 seconds, then add 1.2Kg of dicumyl peroxide and 0.8Kg of triallyl isocyanurate and continue mixing for 30 seconds. The temperature of banburying is 128°C. After the material is mixed on the open mill for 360 seconds, the mixing temperature is 110°C, and then it is pressed into a rubber sheet suitable for processing on a double-roller calender, cooled by an eight-roller cooler, and then packaged to obtain an environmentally friendly, flame-retardant firefighting water Rubber material sample 3 with inner lining.

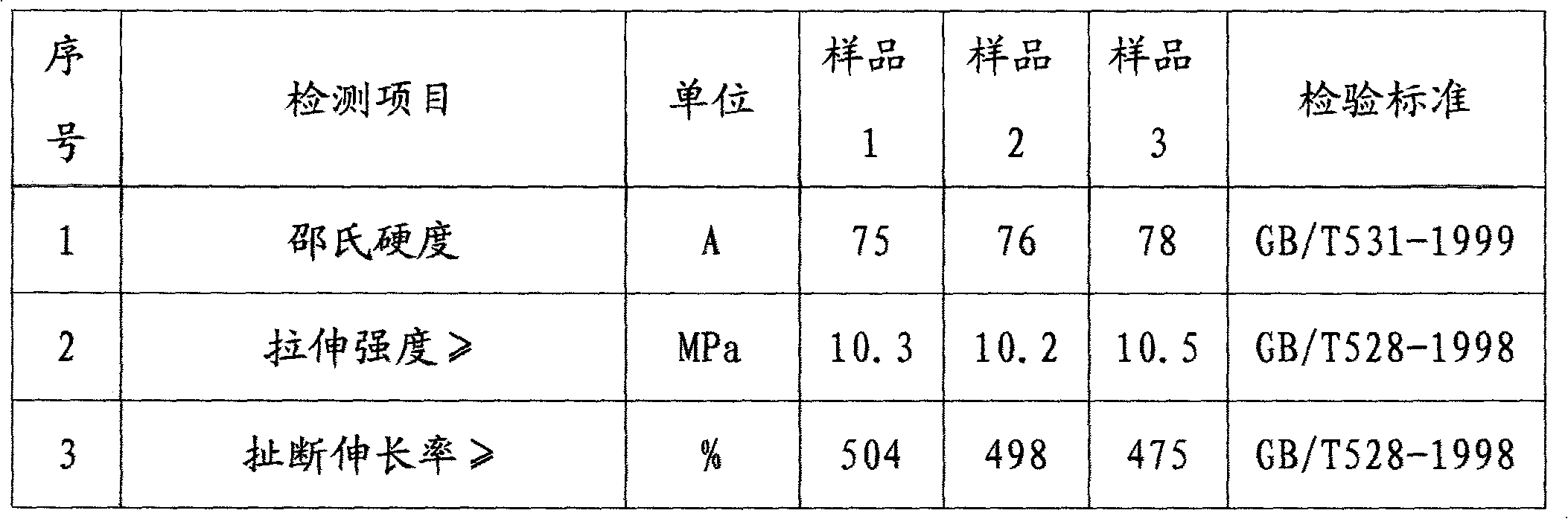

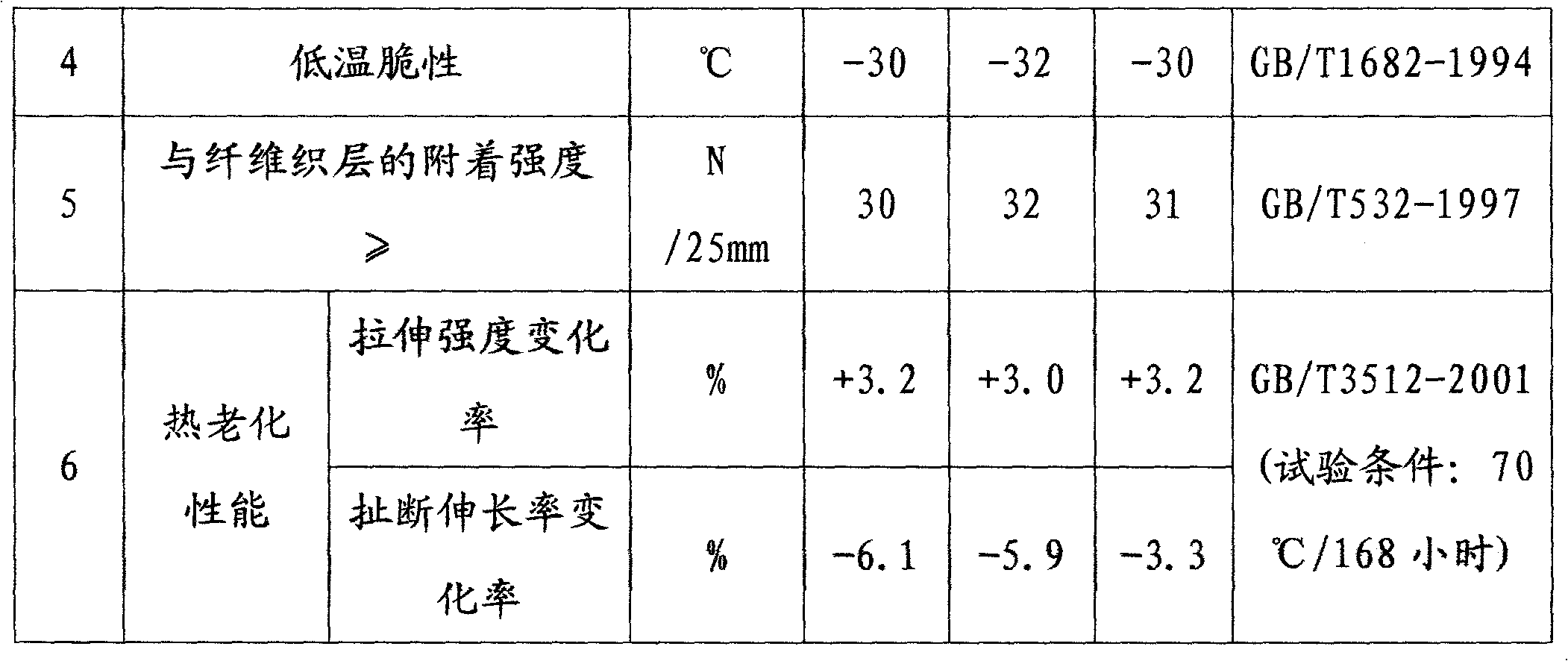

[0038] Embodiment 1, embodiment 2 and embodiment 3 gained environmental protection, flame-retardant fire hose inner liner rubber material sample 1, environmental protection, flame-retardan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com