A method for gas drainage by pre-cracking high-stress and low-porosity coal seams

A technology with high porosity and high stress, which is applied in the direction of gas discharge, earthwork drilling, safety devices, etc., can solve the problems of intensive cross-drilling method with large engineering volume, limited adaptability, and low safety factor, so as to reduce coal The effect of the danger of gas outburst disasters, increasing the density and range of cracks, and the short safety warning distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention provides a system and method for pre-splitting high-stress and low-porosity coal seam pre-splitting, anti-reflection, and gas extraction. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

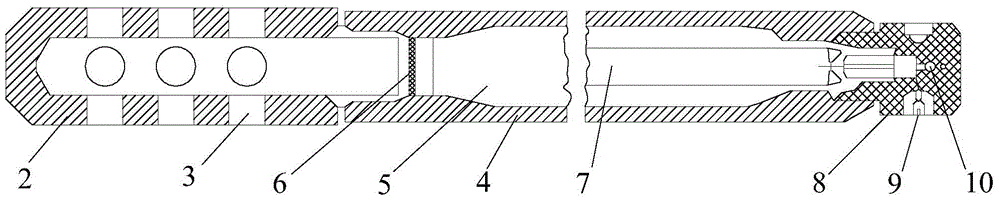

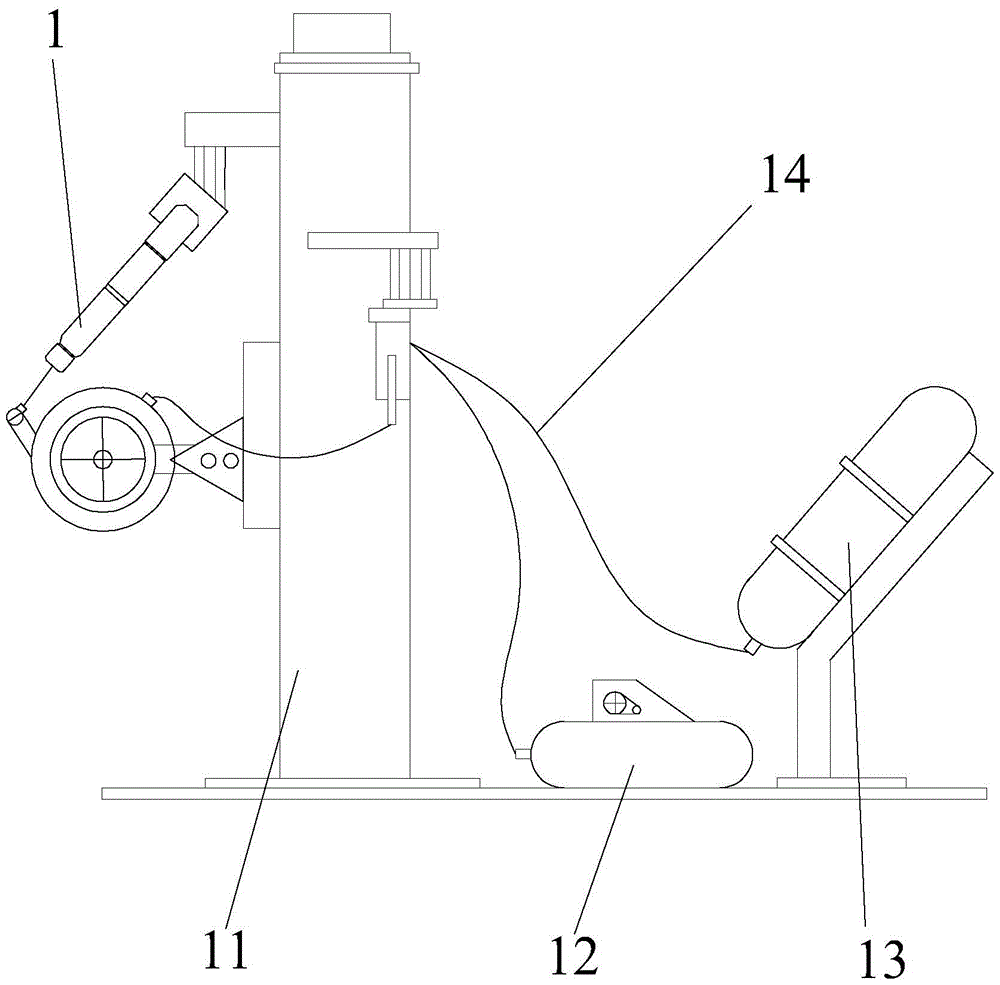

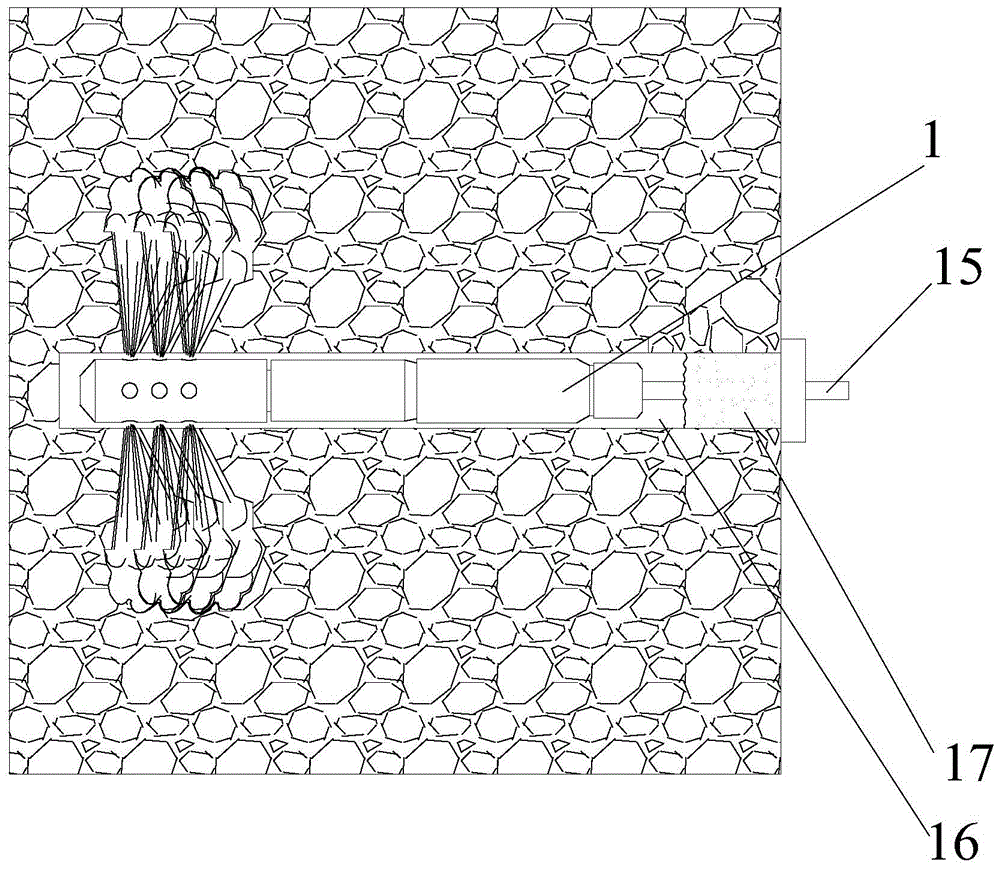

[0017] The invention provides a system and method for pre-splitting, anti-reflection, and drainage gas in high-stress and low-porosity coal seams, such as figure 1 and figure 2 As shown, it includes a pre-cracking device 1, and the pre-cracking device includes an exhaust casing 2, wherein a plurality of exhaust holes 3 are evenly arranged on the exhaust casing 2 to form an exhaust area, and the exhaust The rear part of the casing 2 is provided with a blasting pipe 4, and the blasting pipe 4 is provided with a liquid carbon dioxide liquid storage pipeline 5, and the front end of the liquid carbon dioxide liquid storage pipeline 5 entering the exhaust are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com