Hard environment-friendly flame-retardant polyvinyl chloride foaming board and manufacturing method thereof

A flame-retardant polyvinyl chloride, polyvinyl chloride technology, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of high price, high price, and poor quality of solid wood composite boards, and achieve The production process is simple and easy, the price is low, and the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

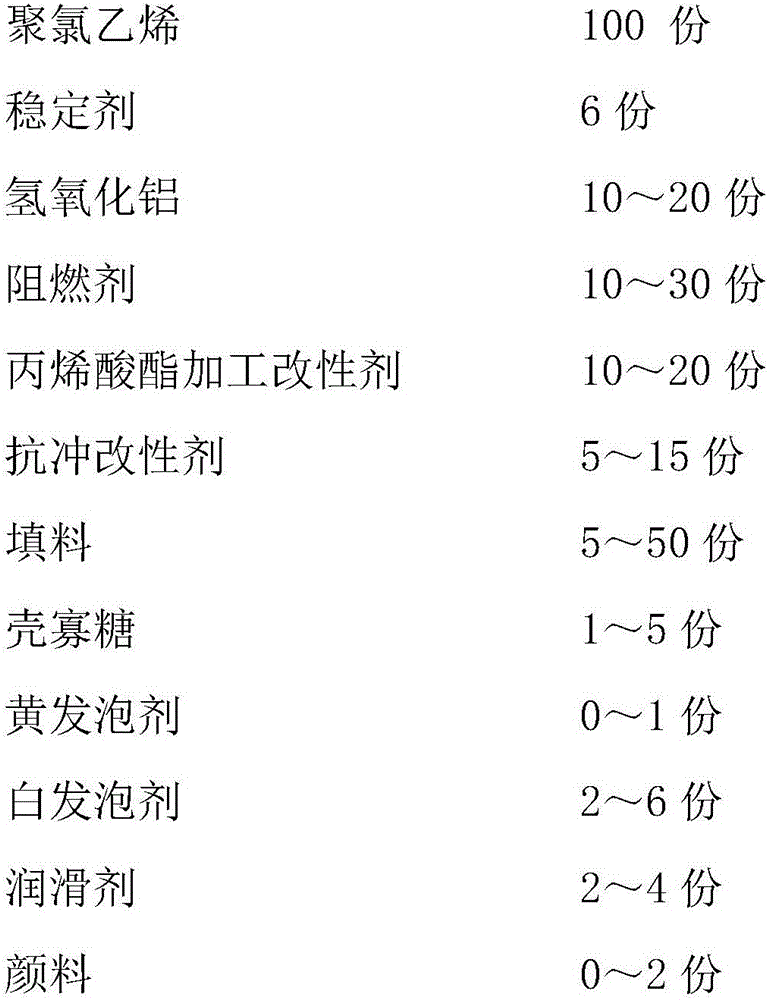

Embodiment 1

[0047] A kind of manufacture method of polyvinyl chloride foaming quality material of lower floor, the polyvinyl chloride resin powder that 100 weight parts polymerization degrees are 650, the calcium-zinc stabilizer of 6 weight parts, the aluminum hydroxide of 10 weight parts and magnesium hydroxide Composite, 10 parts by weight of antimony trioxide, 10 parts by weight of alkyl methacrylate and polymer modifier of alkyl acrylate, 5 parts by weight of chlorinated polyethylene, 5 parts by weight of active nanocarbonic acid Calcium, the chitosan oligosaccharide of 1 weight part, the azodicarbonamide of 1 weight part, the ammonium bicarbonate of 2 weight parts, the stearic acid of 2 weight parts, the titanium dioxide of 1 weight part, after the raw material is mixed evenly, through heating Conical twin-screw extruder with cold mixing, the screw speed is controlled at 15 rpm, the screw barrel heating temperature is 175°C, 165°C, 160°C, 150°C, the screw oil temperature is 80°C, the ...

Embodiment 2

[0049] A kind of manufacture method of lower polyvinyl chloride foam material, 100 parts by weight of polyvinyl chloride resin powder with a degree of polymerization of 1100, 6 parts by weight of organotin stabilizer, 10 parts by weight of aluminum hydroxide, 10 parts by weight of Ammonium octamolybdate, 15 parts by weight of acrylate formic acid modifier, 5 parts by weight of alkyl acrylate impact modifier, 6 parts by weight of talcum powder, 3 parts by weight of chitosan oligosaccharide, 1 part by weight of azo Diisobutyronitrile, the ammonium bicarbonate of 6 weight parts, the stearic acid ester of 2 weight parts, the ultramarine blue of 1 weight part, after the raw material is mixed evenly, enter the conical twin-screw extruder through hot and cold mixing, control screw speed 15 rpm, the heating temperature of the screw barrel is 175°C, 165°C, 160°C, 150°C respectively, the screw oil temperature is 80°C, the mold temperature is 170°C, and the die lip temperature is 120°C to...

Embodiment 3

[0051] A kind of manufacture method of lower polyvinyl chloride foam material, 100 parts by weight of polyvinyl chloride resin powder with a degree of polymerization of 1000, 6 parts by weight of calcium zinc stabilizer, 15 parts by weight of aluminum hydroxide, 15 parts by weight of Calcium phosphomolybdate, 15 parts by weight of styrene modifier, 7 parts by weight of chlorinated polyethylene, 20 parts by weight of active nano calcium carbonate, 5 parts by weight of chitosan oligosaccharide, 1 part by weight of azodicarbonamide , the ammonium carbonate of 3 parts by weight, the stearic acid alcohol compound of 3 parts by weight, the iron red of 2 parts by weight, after the raw materials are mixed evenly, enter the conical twin-screw extruder through hot and cold mixing, control screw speed 15 revs / The screw barrel heating temperature is 180°C, 175°C, 170°C, 160°C respectively, the screw oil temperature is 80°C, the mold temperature is 180°C, and the die lip temperature is 130...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com