A thermoplastic dynamic vulcanization acrylate rubber composition and its preparation method

A technology for vulcanizing acrylate and rubber composition, applied in the field of thermoplastic dynamic vulcanization acrylate rubber composition and preparation thereof, can solve problems such as easy degradation and discoloration, achieve simple processing technology, improve oil resistance and flame retardancy, and comprehensive performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of above-mentioned thermoplastic dynamic vulcanization acrylate rubber composition, comprises the following steps:

[0055] 1) Add ultra-high molecular weight polyvinyl chloride powder, plasticizer, filler, flame retardant, smoke suppressant, heat stabilizer, antioxidant, processing aid and lubricant into a high-speed mixer, and mix well;

[0056] 2) Transfer the material in step 1) to a low-speed mixer, then add acrylate rubber, compatibilizer, ultraviolet light stabilizer, vulcanization crosslinking agent, crosslinking accelerator and antiaging agent, and mix evenly;

[0057] 3) transfer the material in step 2) to a twin-screw extruder for melting and mixing, then transfer the material to a single-screw extruder for extruding, granulating, and cooling to obtain a thermoplastic dynamically vulcanized acrylate rubber composition.

[0058] Preferably, the rotating speed of the high-speed mixer in step 1) is 800-1800 rpm, and the mixing time is 5-30...

Embodiment 1

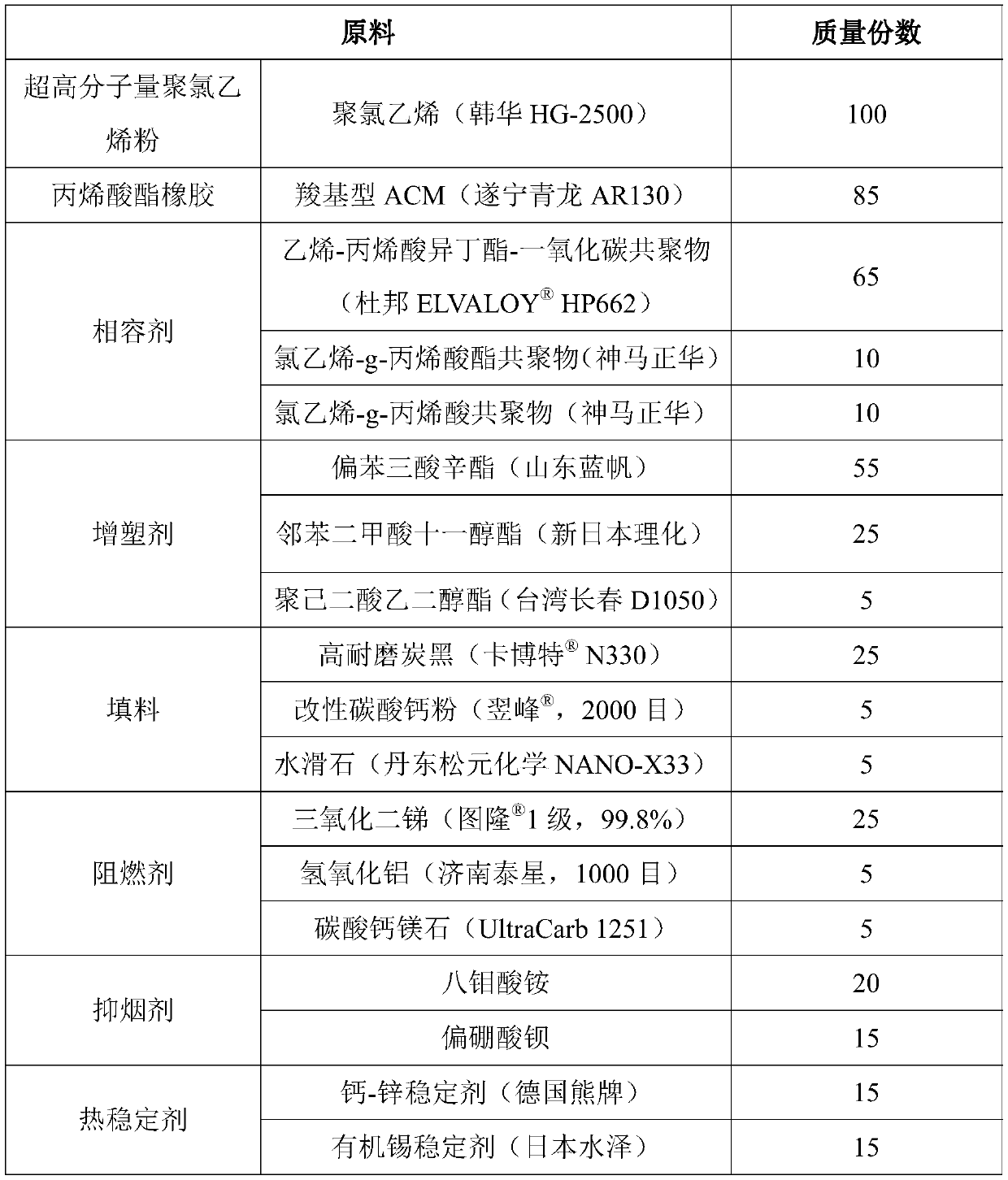

[0063] A kind of thermoplastic dynamically vulcanized acrylate rubber composition, its raw material composition is as shown in the following table:

[0064] Table 1 A raw material composition table of a thermoplastic dynamically vulcanized acrylate rubber composition

[0065]

[0066]

[0067] The preparation method of above-mentioned thermoplastic dynamic vulcanization acrylate rubber composition, comprises the following steps:

[0068] 1) Add ultra-high molecular weight polyvinyl chloride powder, plasticizer, filler, flame retardant, smoke suppressant, heat stabilizer, antioxidant, processing aid and lubricant into the high-speed mixer, mix and stir at 1400rpm for 10 minutes at high speed, After mixing and plasticizing to 110°C, cool until the material temperature is lower than 60°C;

[0069] 2) Transfer the material in step 1) to a low-speed mixer, then add acrylate rubber, compatibilizer, ultraviolet light stabilizer, vulcanization crosslinking agent, crosslinking a...

Embodiment 2

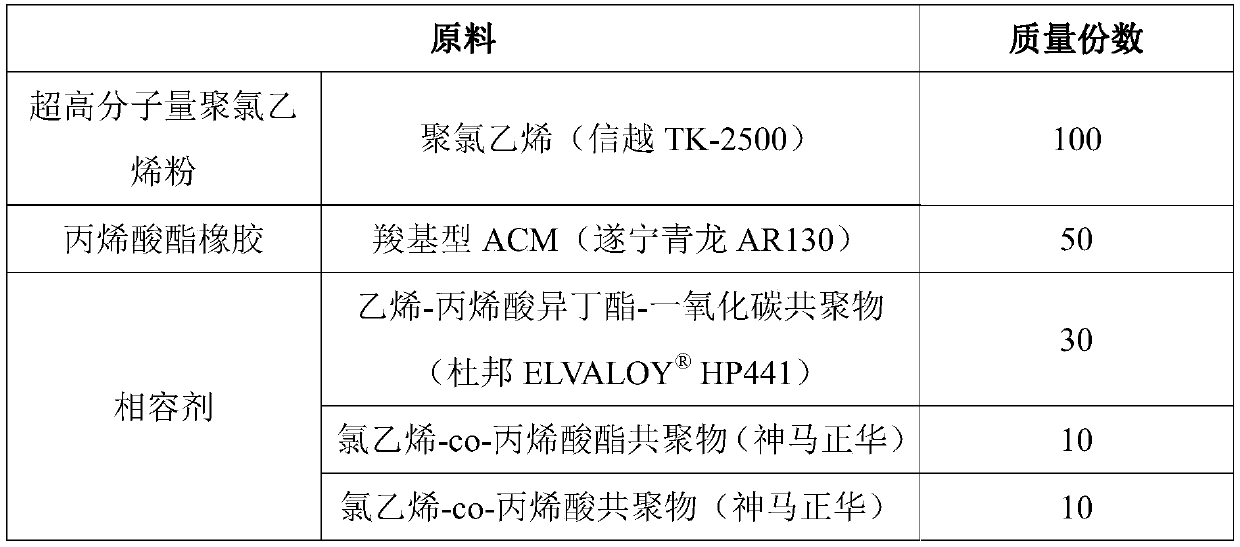

[0072] A kind of thermoplastic dynamically vulcanized acrylate rubber composition, its raw material composition is as shown in the following table:

[0073] Table 2 A raw material composition table of a thermoplastic dynamically vulcanized acrylate rubber composition

[0074]

[0075]

[0076] The preparation method of above-mentioned thermoplastic dynamic vulcanization acrylate rubber composition, comprises the following steps:

[0077] 1) Add ultra-high molecular weight polyvinyl chloride powder, plasticizer, filler, flame retardant, smoke suppressant, heat stabilizer, antioxidant, processing aid and lubricant into the high-speed mixer, mix and stir at 1800rpm for 20min at high speed, After mixing and plasticizing to 110°C, cool until the material temperature is lower than 60°C;

[0078] 2) Transfer the material in step 1) to a low-speed mixer, then add acrylate rubber, compatibilizer, ultraviolet light stabilizer, vulcanization crosslinking agent, crosslinking accele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com