Intermediate temperature-cured epoxy adhesive for coverlay of flexible printed circuit and preparation method thereof

A technology for printed circuit boards and epoxy adhesives, applied in the directions of adhesives, epoxy resin adhesives, carboxyl rubber adhesives, etc., can solve the problems of energy saving and consumption reduction, easy to carry static electricity, and high curing temperature of the encapsulation film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

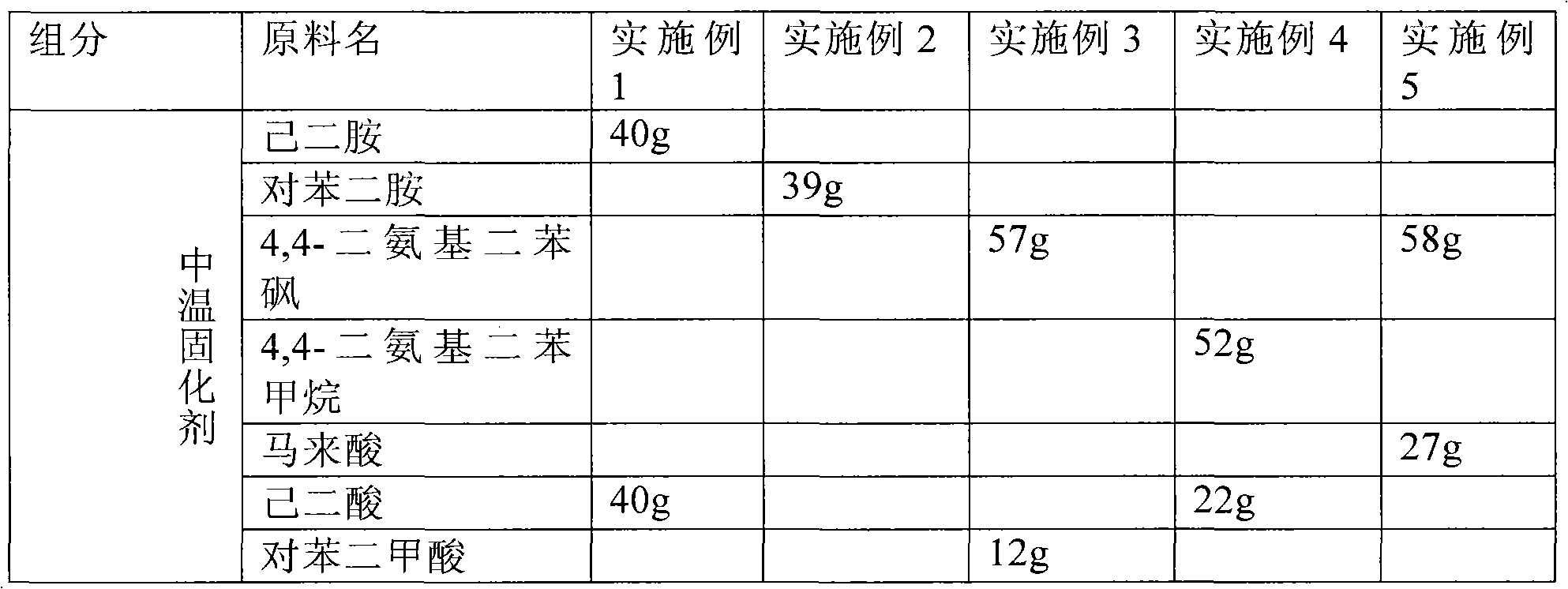

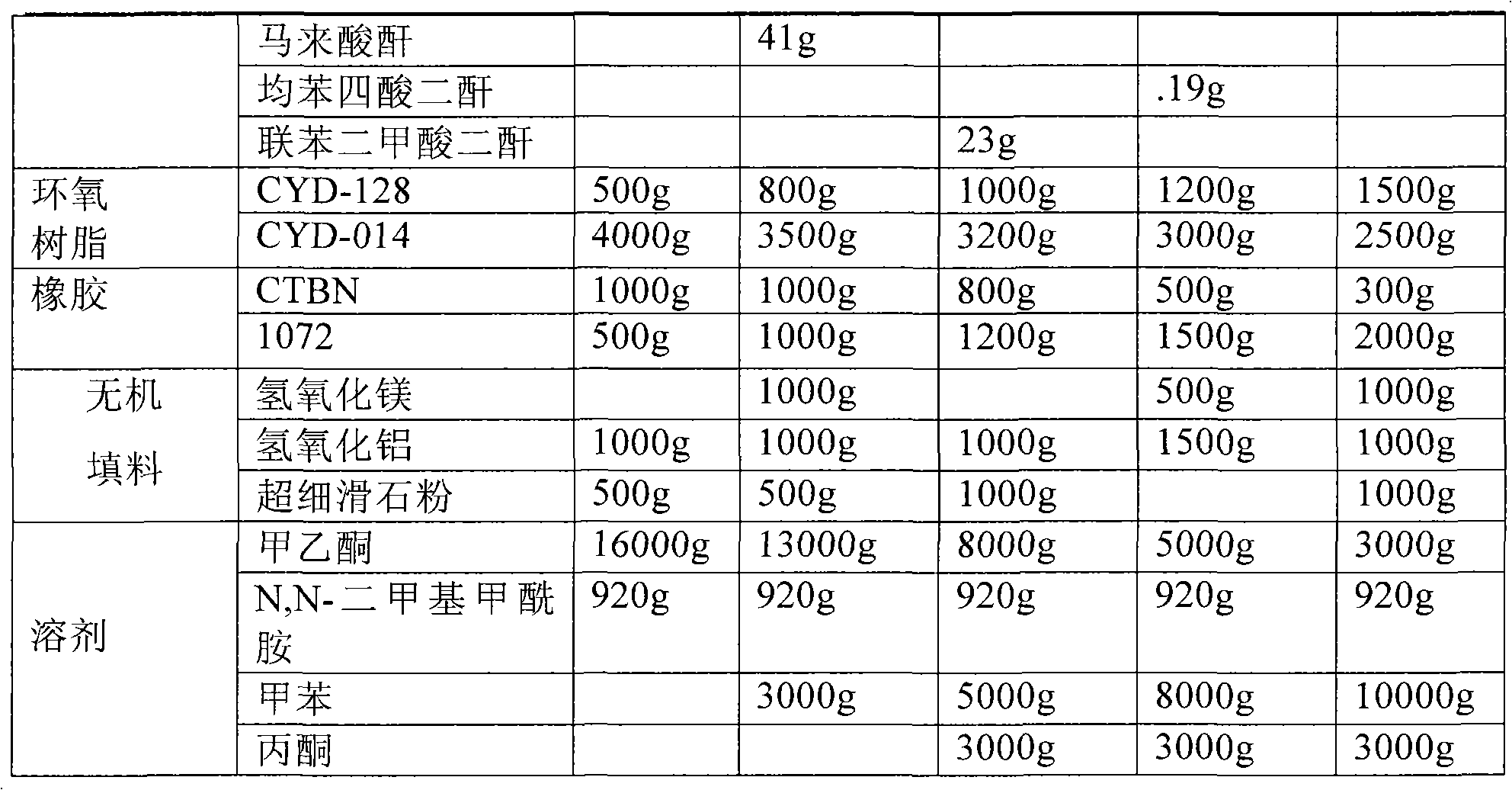

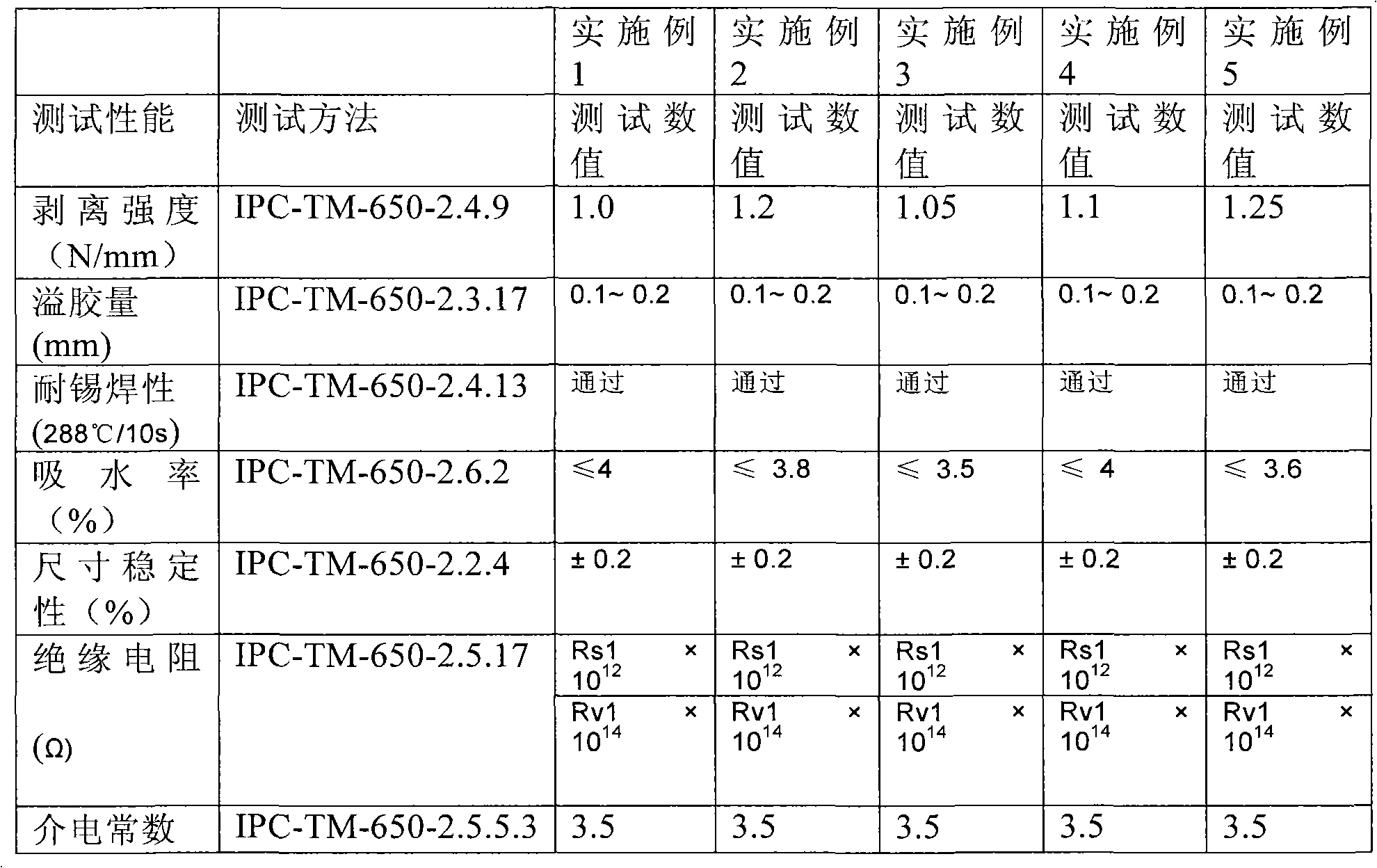

Examples

Embodiment 1

[0022] Add proportioning amounts of p-phenylenediamine, maleic anhydride and N,N-dimethylformamide into a 2500mL container, stir and react at 80°C for 3 hours, and cool to room temperature to prepare a polyamide curing agent. Weigh liquid carboxylated nitrile rubber CTBN and solid carboxylated nitrile rubber 1072 according to the ratio and dissolve them at a concentration of 10% to 20% by mass. After the rubber is completely dissolved, filter through a 300-mesh filter for use.

[0023] Add the proportioned amount of epoxy resin, nitrile rubber, inorganic filler, polyamide curing agent and solvent into a 50L container, stir evenly at room temperature for 3 to 5 hours to form a uniform mixed solution, and filter through a 200-mesh filter After removing a small amount of impurities, it is formulated as an adhesive for medium temperature curing epoxy encapsulation film. Coat the adhesive on the polyimide film with a coating machine, and form a dry glue of 25 μm after baking in the...

Embodiment 2

[0025] According to the proportion of Example 2 in Table 1, the adhesive for medium-temperature epoxy encapsulation film, encapsulation film, and FPC samples were prepared according to the method of Example 1, and the performance test results are shown in Attached Table 2.

Embodiment 3

[0027] According to the proportioning of Example 3 in Table 1, according to the method of Example 1, an adhesive and an encapsulation film for a medium-temperature epoxy adhesive encapsulation film were prepared, and after fast pressing with the copper surface of a flexible copper-clad laminate, after 140 ± 2 ℃, baked for 90 minutes to make FPC samples, performance test results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com