High-heat-conduction flexible aluminum base copper-clad plate for LED heat radiating substrate

An aluminum-based copper-clad laminate, high thermal conductivity technology, applied in the direction of semiconductor devices, carboxyl rubber adhesives, non-polymer adhesive additives, etc., can solve the problem of no flexibility, no test data, and no description in the performance test phase Substrate and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

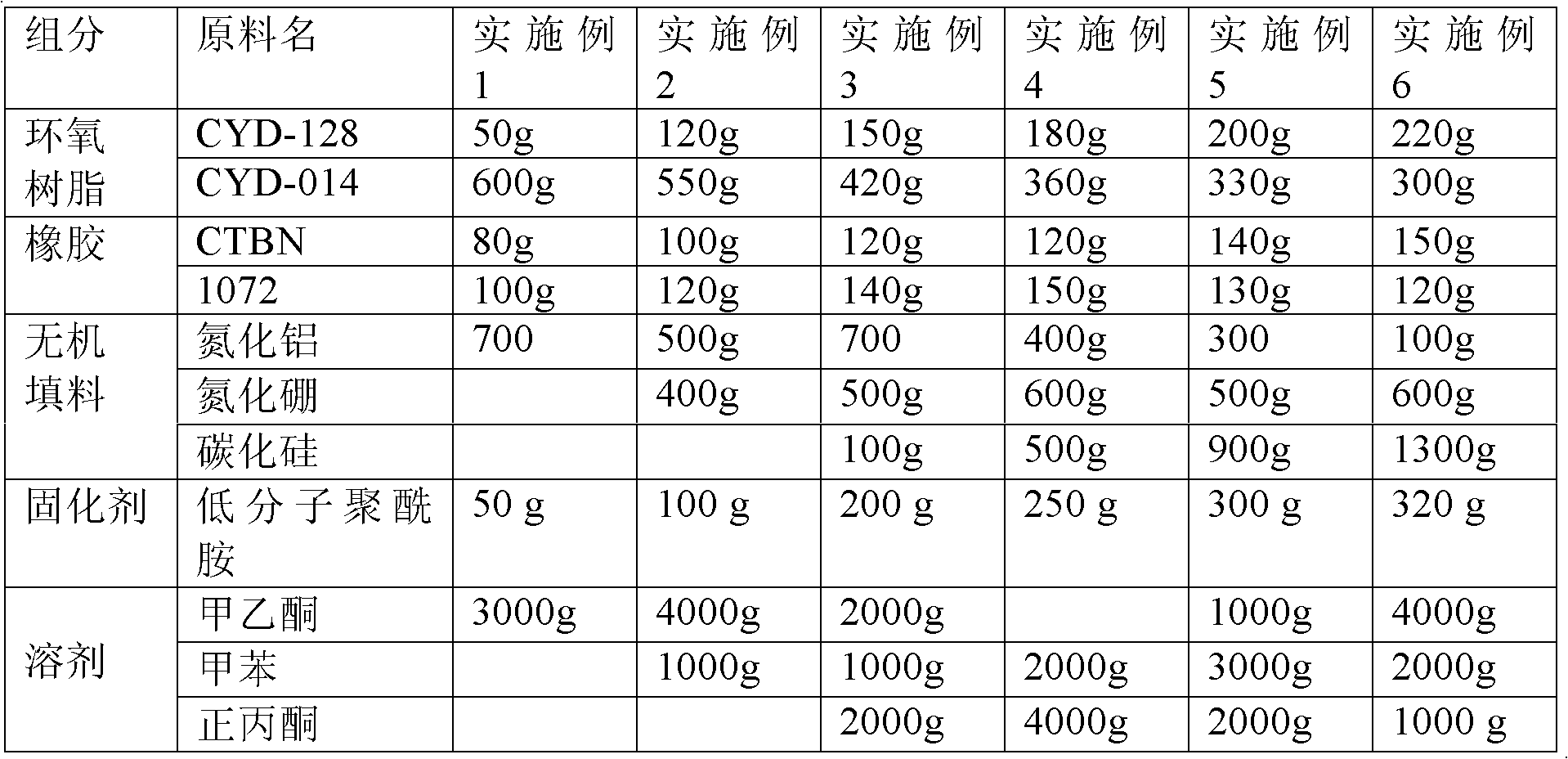

[0040] Add the proportioned amount of epoxy resin, dissolved nitrile rubber, ground inorganic filler, low molecular polyamide curing agent and organic solvent into a 10L container, and stir at room temperature for 3 to 5 hours to form a uniform After the mixed solution is filtered through a 300-mesh filter to remove a small amount of impurities, it is formulated into a high thermal conductivity epoxy resin glue.

[0041] Use the coating machine to coat the adhesive on both sides of the 50 μm polyimide film twice, and form a dry glue of 10 μm on one side after baking in the oven, and then use the compound machine to coat the polyimide film that has been coated with glue. Copper foil and aluminum foil are laminated on both sides of the composite machine respectively, and the temperature of the continuous roll forming of the composite machine is 50±2°C, the line pressure is 2MPa, and the line speed of the roll is 0.5 m / min. Then put it into an oven for post-curing, after stepwise...

Embodiment 2

[0043] The formula of the high thermal conductivity epoxy resin glue is shown in Example 2 in Table 1, and the preparation process of the epoxy resin glue is as described in Example 1.

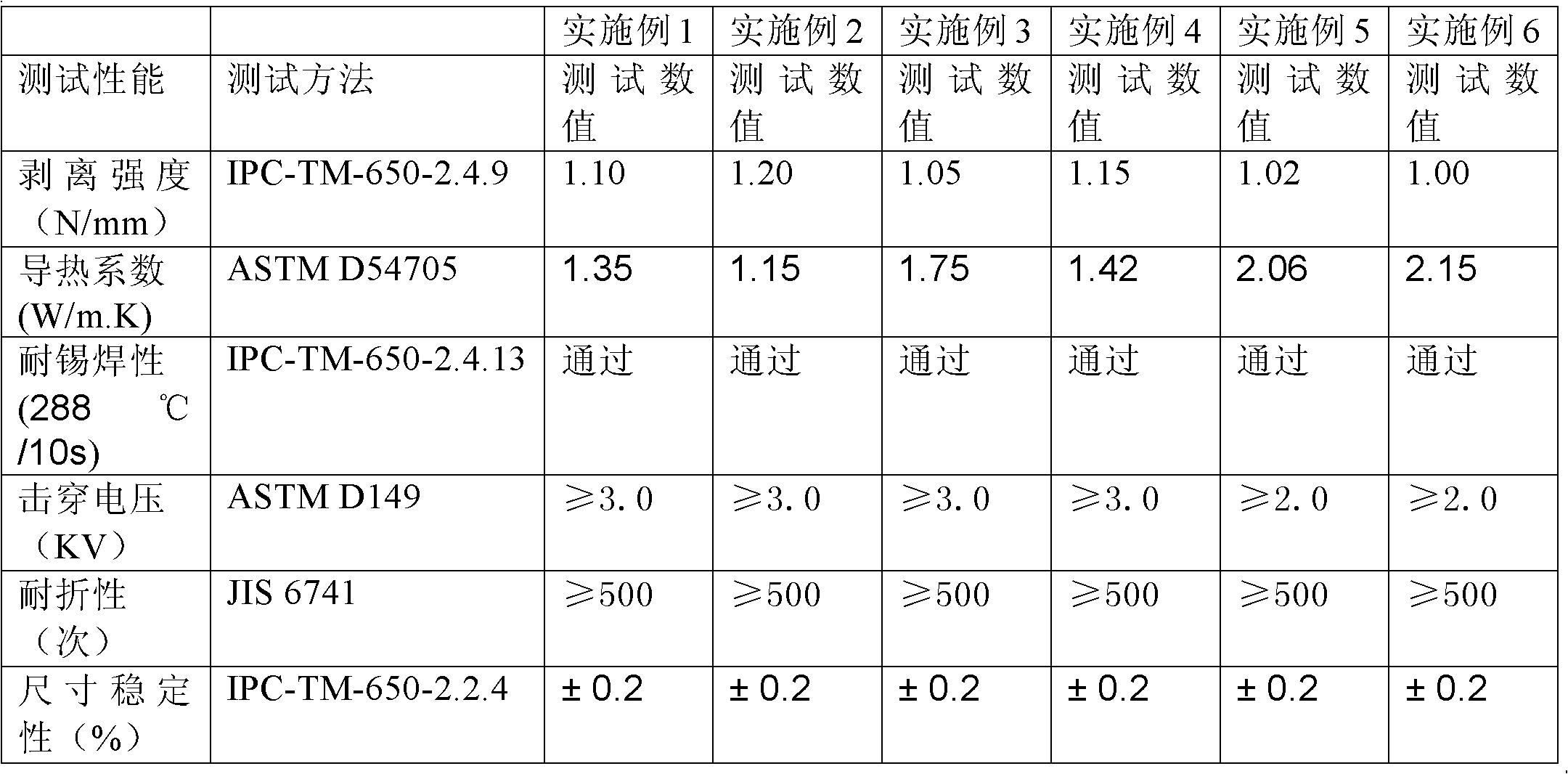

[0044] Use the coating machine to coat the adhesive on both sides of the 35 μm polyimide film twice, and form a dry glue of 15 μm on one side after baking in the oven, and then pass the compound machine on the polyimide film that has been coated with glue. Copper foil and aluminum foil are laminated on both sides of the composite machine respectively. The temperature of the continuous roll forming of the composite machine is 60±2°C, the line pressure is 2MPa, and the line speed of the roll is 1 m / min. Then put it into an oven for post-curing. After stepwise heating, keep the temperature at 140±2°C and keep the curing time for 70 minutes to prepare a high thermal conductivity flexible aluminum-based copper-clad laminate. The performance test is shown in Table 2.

Embodiment 3

[0046] The formula of the high thermal conductivity epoxy resin glue is shown in Example 3 in Table 1, and the preparation process of the epoxy resin glue is as described in Example 1.

[0047] Use the coating machine to coat the adhesive on both sides of the 25μm polyimide film twice, and form a dry glue of 25μm on one side after baking in the oven, and then use the compound machine to coat the polyimide film that has been coated with glue. Copper foil and aluminum foil are laminated on both sides of the composite machine respectively. The temperature of the continuous roll forming of the composite machine is 65±2°C, the line pressure is 3MPa, and the line speed of the roll is 3 m / min. Then put it into an oven for post-curing. After stepwise heating, keep the temperature at 145±2°C and keep the curing time for 75 minutes to prepare a highly thermally conductive flexible aluminum-based copper-clad laminate. The performance test is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com