Low-halogen-content fire-retardant adhesive and flexible copper clad laminate prepared from same

A flame retardant adhesive and content technology, used in the field of flame retardant adhesives and flexible copper clad laminates, can solve the heat resistance of the adhesive, the decrease in flexibility and adhesion, the resistance to dip soldering, the resistance to bending, the poor resistance to bending, the smoke It can achieve the effects of excellent flexibility, reducing bromine content, improving heat resistance and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

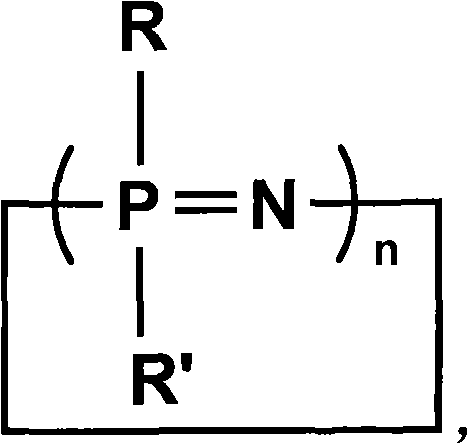

[0051] The preparation steps of the flame retardant adhesive of the present invention are as follows: firstly dissolve the synthetic rubber and the biphenyl type epoxy resin into 20% and 60% pre-solutions respectively with methyl ethyl ketone, then mix the glues in a certain order, mix the curing agent, the curing accelerator After the agent is dissolved, add the remaining components and pre-solution, and fully mix by using mixing and dispersing equipment such as ball mill, pot mill, sand mill, high-shear stirring disperser or high-speed disperser to prepare a flame-retardant adhesive.

[0052] The above-mentioned adhesive is used to prepare flexible copper-clad laminates: the flame-retardant adhesive prepared above is coated on a polyimide film, the solvent is removed by oven baking, and the adhesive is partially cross-linked and cured, and then laminated with copper foil, and finally placed on the Curing at high temperature in an oven to make a flexible copper clad laminate. ...

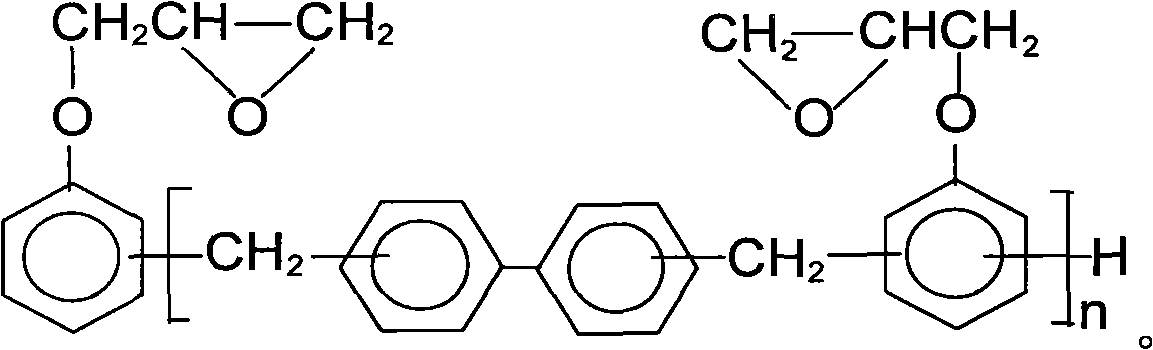

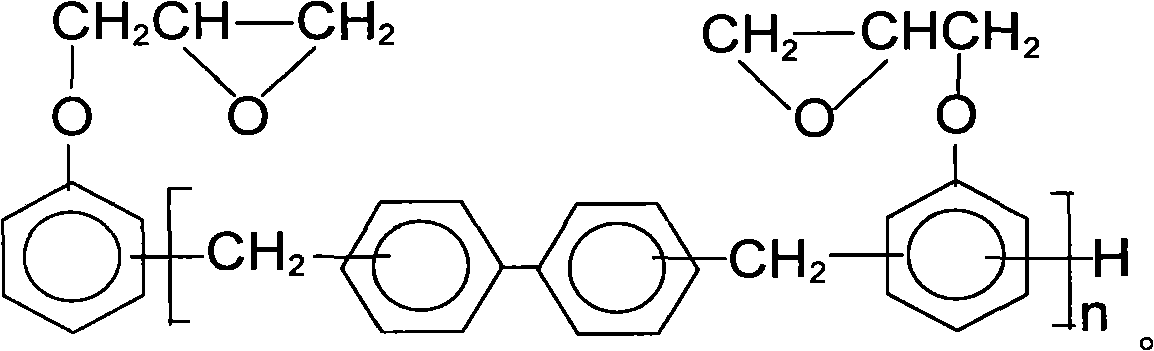

Embodiment 1

[0056] Synthetic rubber (trade name Nipol 1072CGX, manufactured by U.S. ZEON company, solid content 100%) 35 parts by weight, brominated epoxy resin (trade name DER530-A80, manufactured by DOW company, epoxy equivalent 425-440g / eq, solid content 80 %) 25 parts by weight, brominated epoxy resin (trade name Epiclon 153-60M, manufactured by Dainippon Ink Co., Ltd., epoxy equivalent 390-410g / eq, solid content 60%) 33.3 parts by weight, biphenyl type epoxy resin (trade name NC-3000-H, manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 288g / eq, solid content 100%) 25 parts by weight, 4,4'-diaminodiphenyl sulfone 10.1 parts by weight (India Atul Corporation Manufacturing), 1-cyanoethyl-2-ethyl-4-methylimidazole (trade name 2E4MZ-CN, manufactured by Japan Shikoku Chemicals Co., Ltd.) 0.2 parts by weight, antioxidant 1010 (manufactured by Ciba, Switzerland) 0.3 weight Parts, 0.5 parts by weight of ion exchanger (trade name IXE-700, manufactured by Toagosei Co., Ltd.), 15 parts b...

Embodiment 2

[0058] Synthetic rubber (trade name Nipol 1072CGX, U.S. ZEON company manufactures, solid content 100%) 17.5 parts by weight, synthetic rubber XER-32 (Japan JSR Co., Ltd. manufactures, solid content 100%) 17.5 parts by weight brominated epoxy resin (trade name DER530-A80, manufactured by DOW Company, epoxy equivalent 425-440g / eq, solid content 80%) 25 parts by weight, brominated epoxy resin (trade name Epiclon 153-60M, manufactured by Dainippon Ink Co., Ltd., epoxy equivalent 390 -410g / eq, solid content 60%) 33.3 parts by weight, biphenyl type epoxy resin (trade name NC-3000-H, manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 288g / eq, solid content 100%) 25 weight Parts, 10.1 parts by weight of 4,4'-diaminodiphenyl sulfone (manufactured by Attu, India), 1-cyanoethyl-2-ethyl-4-methylimidazole (trade name 2E4MZ-CN, Japan Shikoku Chemicals Co., Ltd. Co., Ltd.) 0.2 parts by weight, antioxidant 1010 (made by Ciba, Switzerland) 0.3 parts by weight, ion exchanger (trade name ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com