n-Type conductive aluminum nitride semiconductor crystal and manufacturing method thereof

a technology of conductive aluminum nitride and semiconductor crystal, which is applied in the direction of crystal growth process, polycrystalline material growth, chemically reactive gas, etc., can solve the problems of deterioration of device properties, inability to efficiently produce aln single crystal film having enough thickness to obtain self-supporting substrate, and inability to produce aln single crystal film having enough thickness to achieve the effect of self-supporting substrate, good electric properties, and marked reduction of halogen impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

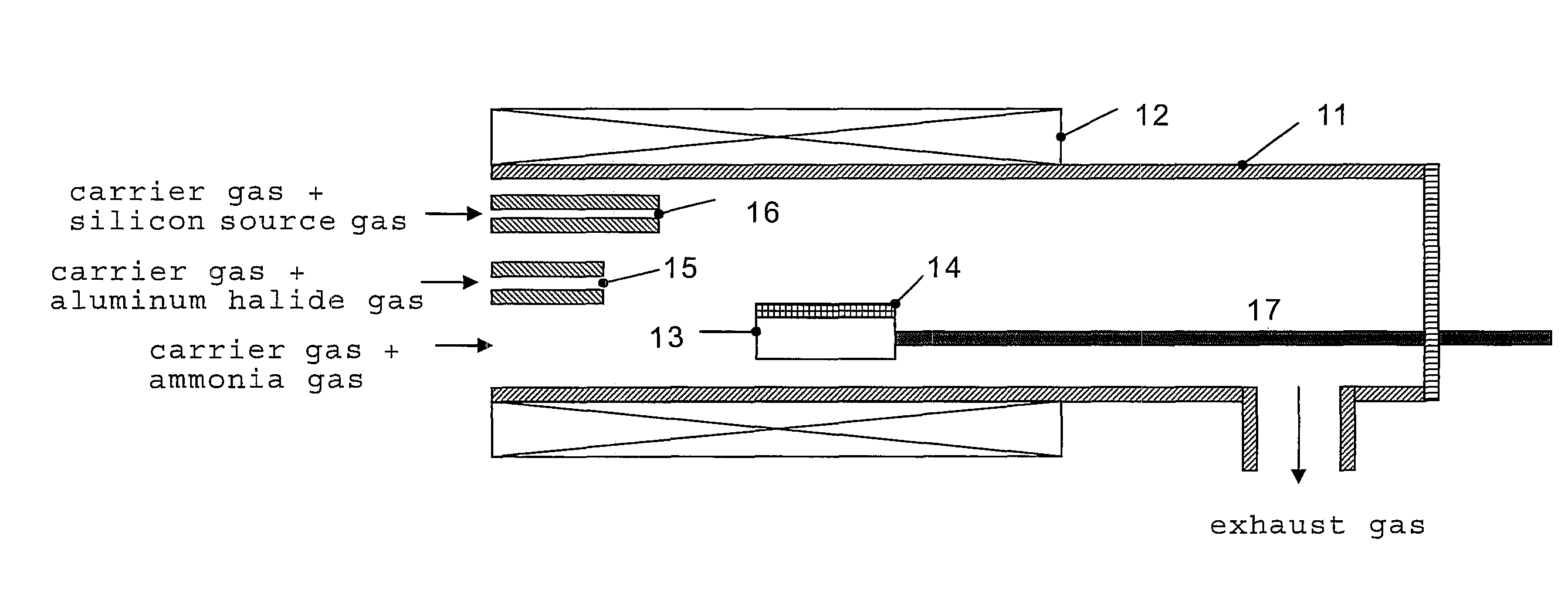

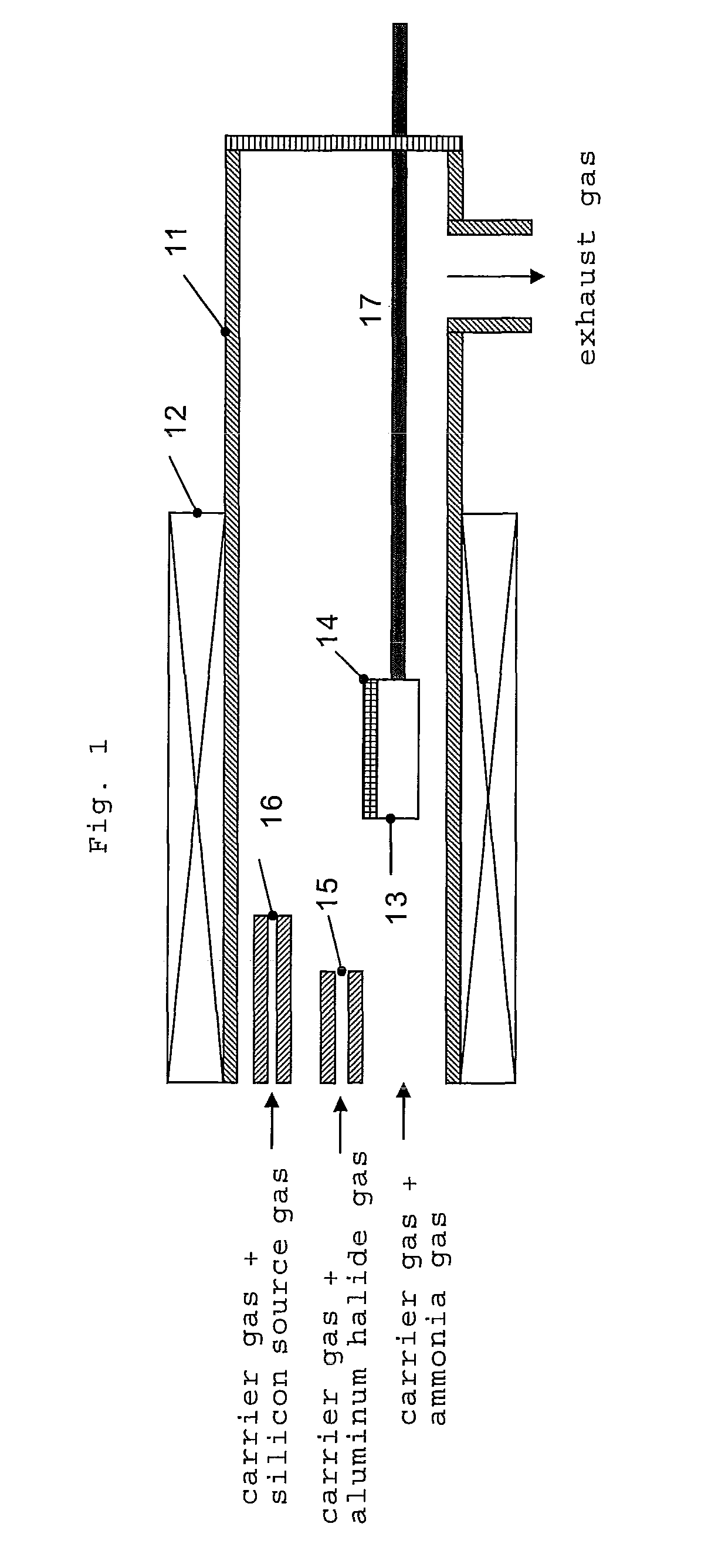

[0072]In this example, the n-type conductive aluminum nitride semiconductor crystal was grown using the reaction tube shown in the FIG. 1. In the example, the aluminum trichloride gas was generated by reacting the metal aluminum set upstream the reaction tube with hydrogen chloride gas at 500° C. Also, the sapphire (0001) substrate set on the susceptor could be heated to 1,200° C. or more by supplying the electric power from the outside to the carbon heating element using a resistance heating furnace as the external heating apparatus as well as using a susceptor consisted of the pyrolytic boron nitride which has a carbon heating element inside the reaction tube. Further, the aluminum trichloride gas used as the aluminum source gas and ammonia gas used as the nitrogen source gas were reacted to grow aluminum nitride. As the silicon source, SiCl4 was used.

[0073]First, a sapphire (0001) substrate was set on the susceptor in the reaction tube, in the normal pressure, 300 sccm of hydroge...

example 2

[0077]In this example, all procedures and conditions were the same in growing the n-type conducting aluminum nitride semiconductor crystal except that the quantity of SiCl4 supplied during growing the second stage i.e. growing the n-type conducting aluminum nitride semiconductor crystal was 0.005 times the partial pressure of aluminum trichloride gas supplied.

[0078]The film thickness of the grown n-type conducting aluminum nitride semiconductor crystal was 5.7 μm and the growing rate was 11.4 μm / h. The silicon concentration measured by the secondary ion mass spectrometer was 1×1020 cm−3, the oxygen concentration was 1×1019 cm−3, and the chlorine concentration was not more than 1×1018 cm−3. The dislocation density was calculated according to the transmission electron microscope and it was 1×1010 cm−2. The resistivity measured by the noncontact resistivity measuring apparatus was 38 Ω·cm. When observing the surface by the atomic force microscope, it was smoothed to the extent that the...

example 3

[0079]The aluminum nitride epitaxial layer which has the thickness of 130 μm was laminated on the silicon substrate using the reaction tube shown in FIG. 1 based on the method disclosed in “Embodiment 1” of JP-A 2005-252248, then it was immersed in a etchant prepared such that 50% of hydrofluoric acid, concentrated nitric acid, 98% of acetic acid and the pure water were 1:2:1:4 by volume ratio to dissolve only the silicon base which was the primary substrate, with result that the aluminum nitride selfsupporting substrate was obtained.

[0080]Subsequently, all the same procedures and conditions were used to grow the n-type conducting aluminum nitride semiconductor crystal except that the above aluminum nitride selfsupporting substrate was used instead of the sapphire (0001) substrate used in the Example 1.

[0081]The film thickness of the grown n-type conducting aluminum nitride semiconductor crystal was 5.2 μm and the growing rate was 10.4 μm / h. The silicon concentration measured by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption coefficient | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com