A kind of post-processing technology of isophorone prepared by liquid-phase condensation method of acetone

A technology of isophorone and acetone liquid, applied in the field of post-processing technology of organic synthesis, can solve the problems of significant energy consumption, increase the difficulty of post-processing, quality impact, etc., reduce energy consumption, improve yield, and realize recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Tray structure of tray column with cylindrical spray hood

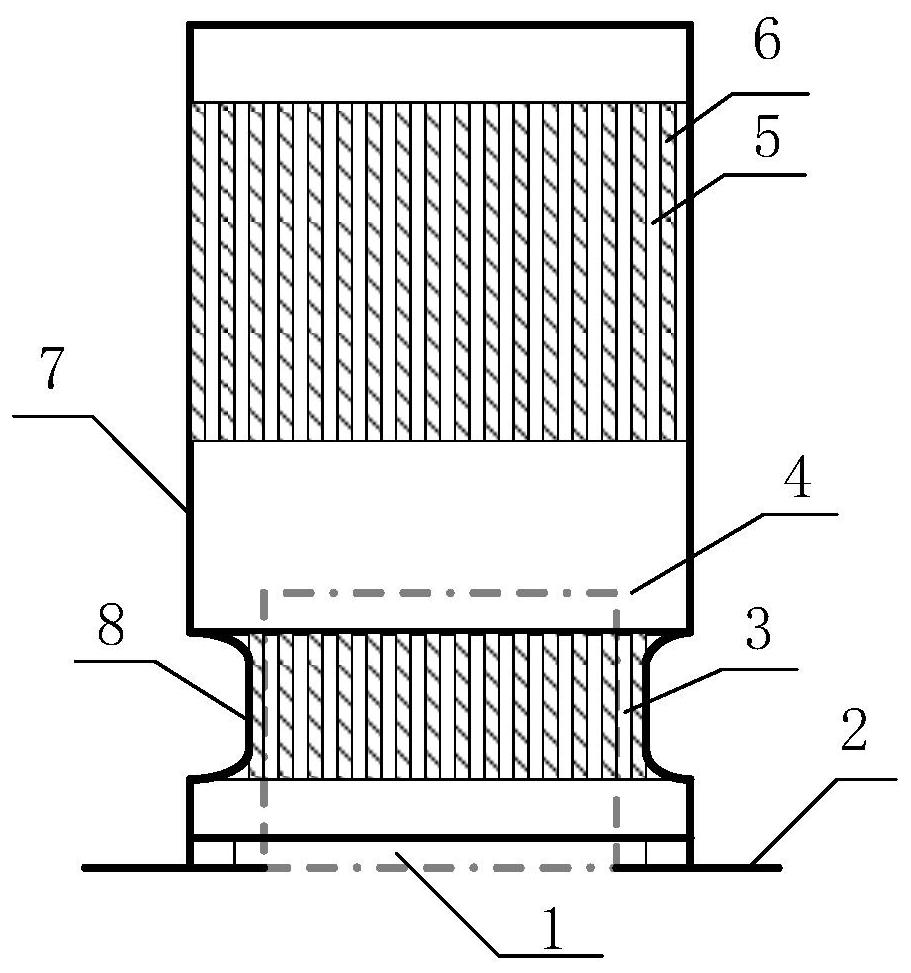

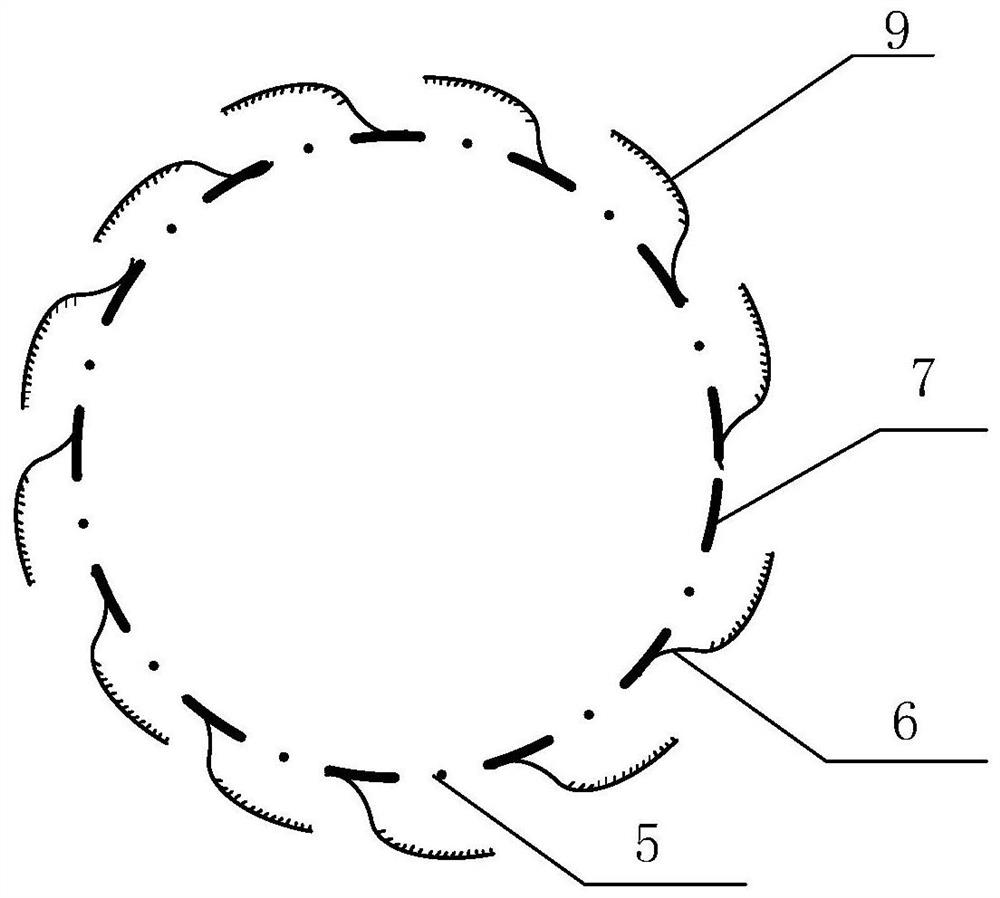

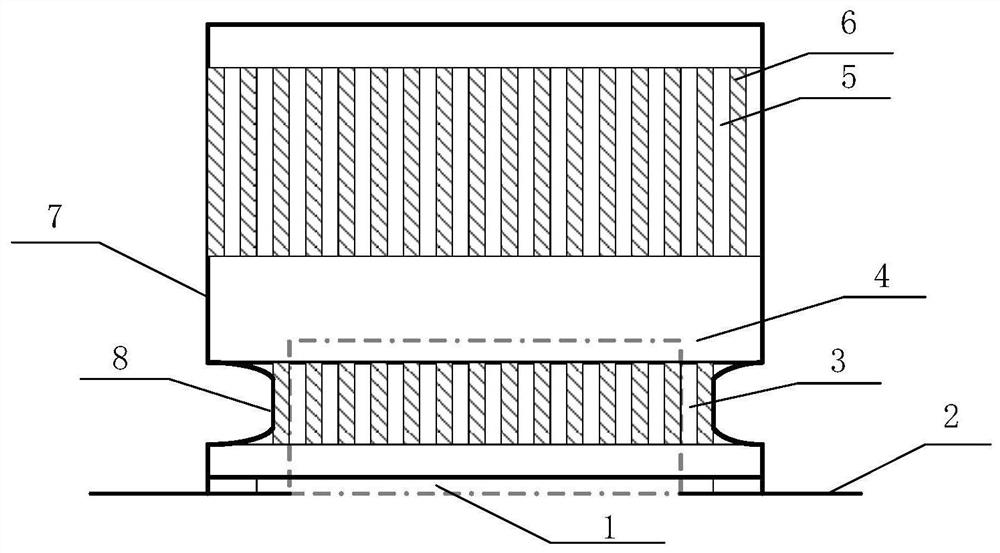

[0042] Cylindrical injection element scheme as attached figure 1 and 2 As shown, it includes a lower suction hole 1; a tray 2; an upper suction hole 3; an air riser 4; a spray hole 5; Among them, the gas riser 4 is cylindrical with a diameter of 30mm, installed on the tray 2, 50mm higher than the tray 2, the overflow weir is 80mm high, and the total height of the jet cover is 200mm, installed on the upper part of the gas riser 4, and the whole is also cylindrical The upper suction hole 3 has a constriction toward the inside of the spray cover, and the upper part of the spray cover body 7 is provided with rectangular spray holes 5 that are vertically arranged and parallel to each other. The diameter of the upper part of the spray hood is 60mm, the height of the upper suction center from the tray 2 is 30mm, the diameter of the neck is 45mm, the cross section of the suction hole is rectangular, the width of the ...

Embodiment 2

[0046] The schematic diagram of the liquid phase condensation process of acetone is attached Figure 5 As shown, the acetone and KOH aqueous solution are preheated by the preheater 12 and fully mixed by the mixer 13 and then enter the first reactor 14 and the reactive distillation column 15. The reactive distillation column 15 is operated at 3.0MPa, and the acetone processing capacity is 600kg / h, the catalyst is NaOH, and the concentration is 0.1% of the total reaction liquid mass flow; 30% of the stream from the 15-column still of the reactive distillation column is sent to the isophorone demulsification recovery tower, and the The mass ratio of organic phase and water is 1:1, and the operating pressure of the isophorone demulsification recovery tower is 3.1 MPa. The diameter of the isophorone demulsification recovery tower is 800mm, including 50 trays in the present invention, and each tray is provided with 28 circular spray caps, and the circular spray cap adopts the desig...

Embodiment 3

[0049] The schematic diagram of the liquid phase condensation process of acetone is attached Figure 5 As shown, the acetone and KOH aqueous solution are preheated by the preheater 12 and fully mixed by the mixer 13 and then enter the first reactor 14 and the reactive distillation column 15. The reactive distillation column 15 is operated at 5.0MPa, and the acetone processing capacity is 720kg / h, the catalyst is KOH, and the concentration is 0.05% of the total reaction liquid mass flow; 60% of the stream from the reactive distillation tower tower reactor is sent to the isophorone demulsification recovery tower, and the organic The mass ratio of phase and water is 1:2, and the operating pressure of the isophorone demulsification recovery tower is 5.1 MPa. The diameter of the isophorone demulsification recovery tower is 800mm, including 50 trays of the present invention, each tray is provided with 5 strip-shaped spray caps, and the strip-shaped spray cap adopts the design of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com