Electroplating solution composition and technology for electroplating high-iron and low-tin alloy

A technology of tin alloy and electroplating solution, which is applied in the field of iron-tin alloy electroplating process and the composition of electroplating solution for electroplating high-iron-low-tin alloy, which can solve the problems of poor wear resistance, limited use, harmful to human body, etc., and achieve smooth and smooth surface, good The effect of surface binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Pre-plating treatment

[0023] After grinding and polishing the plated copper piece, place it in acetone and ultrasonically wash it for 10 minutes, then put it in the temperature 30°C, the concentration is 4g L -1 Soak in hydrochloric acid solution for 10 minutes.

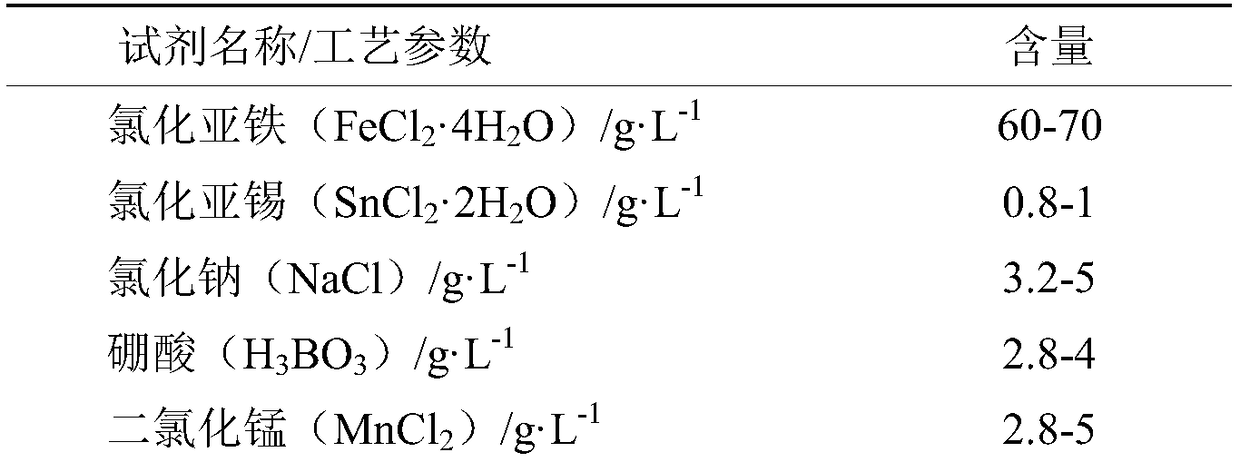

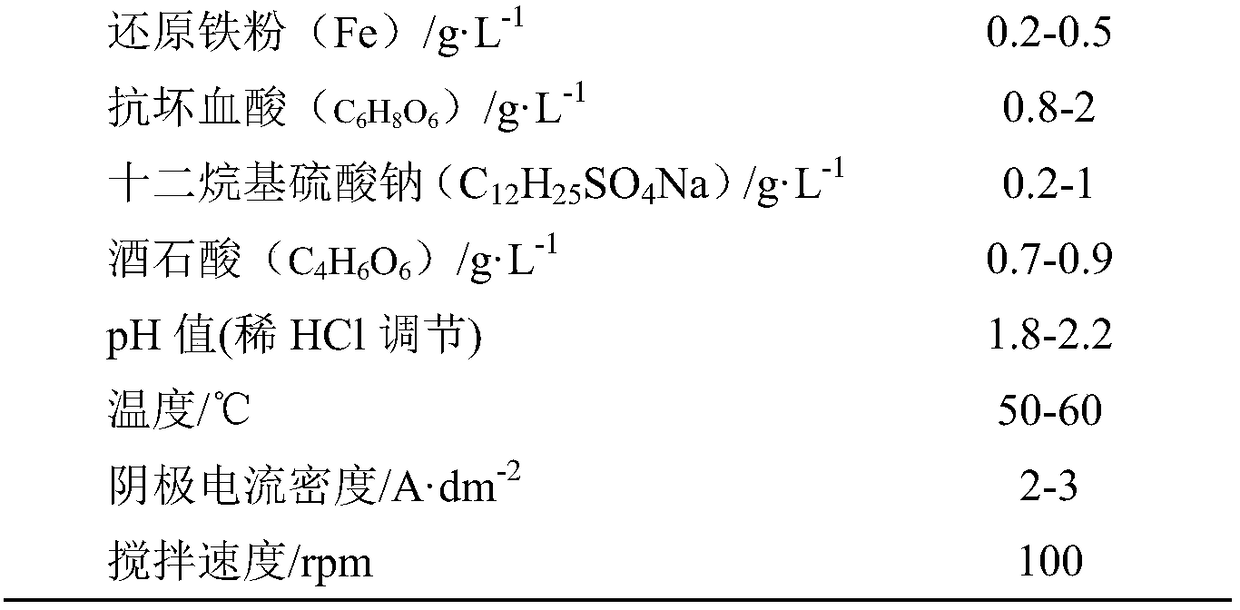

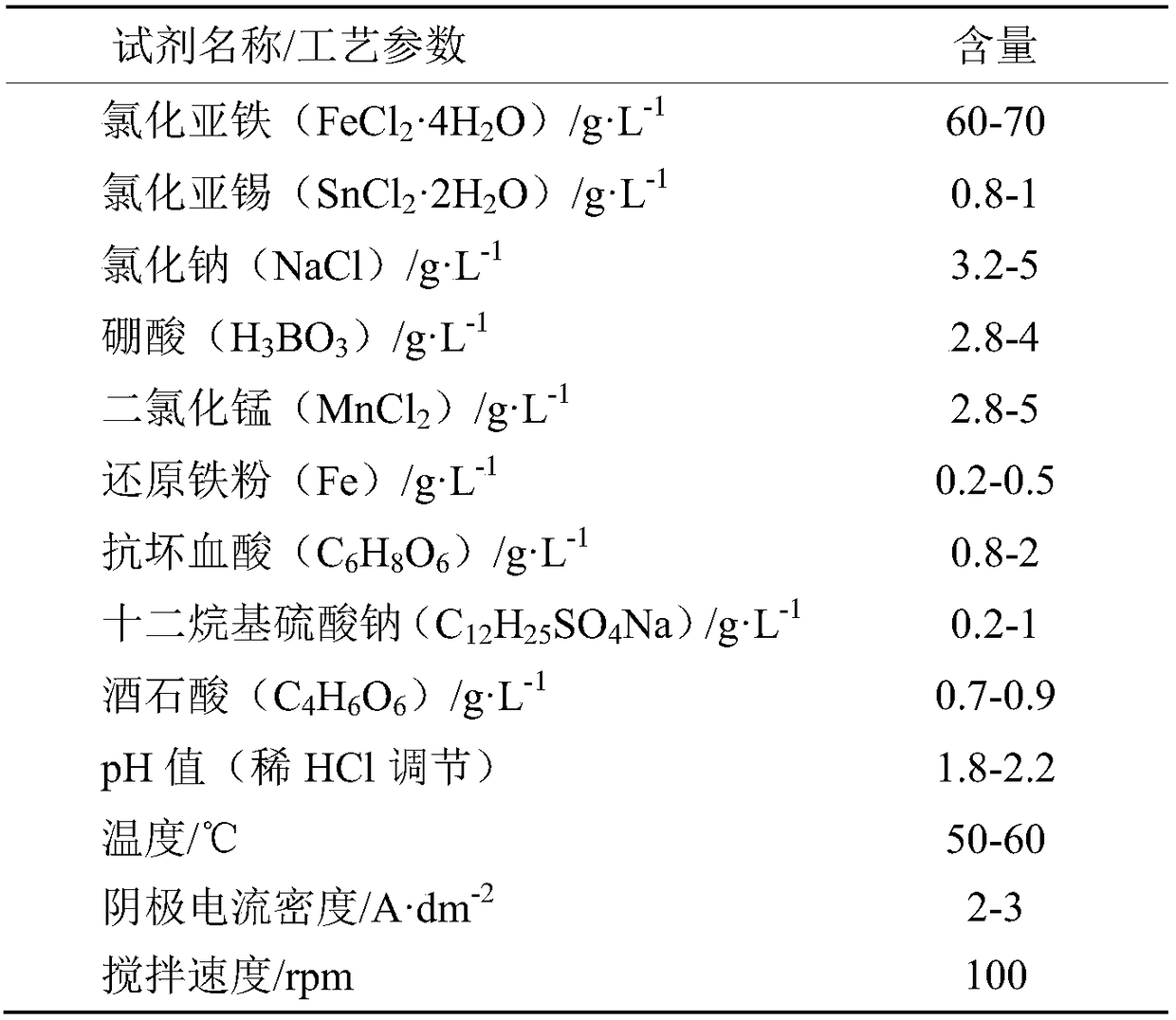

[0024] 2) Bath composition and electroplating

[0025] Bath composition: FeCl 2 4H 2 O 60g·L -1 , SnCl 2 2H 2 O 0.8g·L -1 , NaCl 3.2g·L -1 , H 3 BO 3 2.8g·L -1 , MnCl 2 2.8g·L -1 , ascorbic acid 0.8g L -1 , reduced iron powder 0.2g·L -1 , sodium lauryl sulfate 0.2g L -1 , tartaric acid 0.7g·L -1 , and adjust the pH to 1.8 with dilute HCl.

[0026] Electroplating: Connect the pre-plating copper sheet to the negative electrode (cathode) of the DC power supply, and place it in the above electroplating solution. The anode (connected to the positive electrode of the power supply) is an iron sheet. At a temperature of 50°C, the current density is 2A·dm -2 , the electroplating time is 10min, a...

Embodiment 2

[0031] 1) Pre-plating treatment

[0032] After grinding and polishing the plated copper piece, place it in acetone and ultrasonically wash it for 10 minutes, then put it in the temperature 35°C, the concentration is 5g L -1 Soak in hydrochloric acid solution for 15 minutes.

[0033] 2) Bath composition and electroplating

[0034] Bath composition: FeCl 2 4H 2 O 65g·L -1 , SnCl 2 2H 2 O 0.9g L -1 , NaCl 4.1g L -1 , H 3 BO 3 3.4g·L -1 , MnCl 2 3.9g·L -1 , ascorbic acid 1.4g·L -1 , reduced iron powder 0.4g·L -1 , sodium lauryl sulfate 0.6g L -1 , tartaric acid 0.8g·L -1 , mixed to a volume of 250 ml, and adjusted to pH 2 with dilute HCl.

[0035] Electroplating: Connect the pre-plating copper sheet to the negative electrode (cathode) of the DC power supply, and place it in the above electroplating solution. The anode (connected to the positive electrode of the power supply) is an iron sheet. At a temperature of 55°C, the current density is 2.5A·dm -2 , the elec...

Embodiment 3

[0040] 1) Pre-plating treatment

[0041] After grinding and polishing the plated copper piece, put it in acetone and ultrasonically wash it for 10 minutes, then put it in the temperature of 40°C, the concentration is 6g L -1 Soak in hydrochloric acid solution for 20 minutes.

[0042] 2) Bath composition and electroplating

[0043] Bath composition: FeCl 2 4H 2 O 70g·L -1 , SnCl 2 2H 2 O 1g L -1 , NaCl 5g·L -1 , H 3 BO 3 4g·L -1 , MnCl 2 5g·L -1 , ascorbic acid 2g·L -1 , reduced iron powder 0.5g·L -1 , Sodium Lauryl Sulfate 1.0g·L -1 , tartaric acid 0.9g·L -1 , mixed to a volume of 250 ml, and adjusted to pH 2.2 with dilute HCl.

[0044] Electroplating: connect the pre-plating copper sheet to the negative electrode (cathode) of the DC power supply, and place it in the above electroplating solution. The anode (connected to the positive electrode of the power supply) is an iron sheet. At a temperature of 60°C, the current density is 3A·dm -2 , the electroplati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com