Method for preparing isophorone by acetone liquid condensation with alkali catalyst

A technology of isophorone and catalyst, applied in the field of preparation of isophorone, can solve the problems of low single-pass conversion rate of acetone, low effective selectivity of isophorone, high process cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

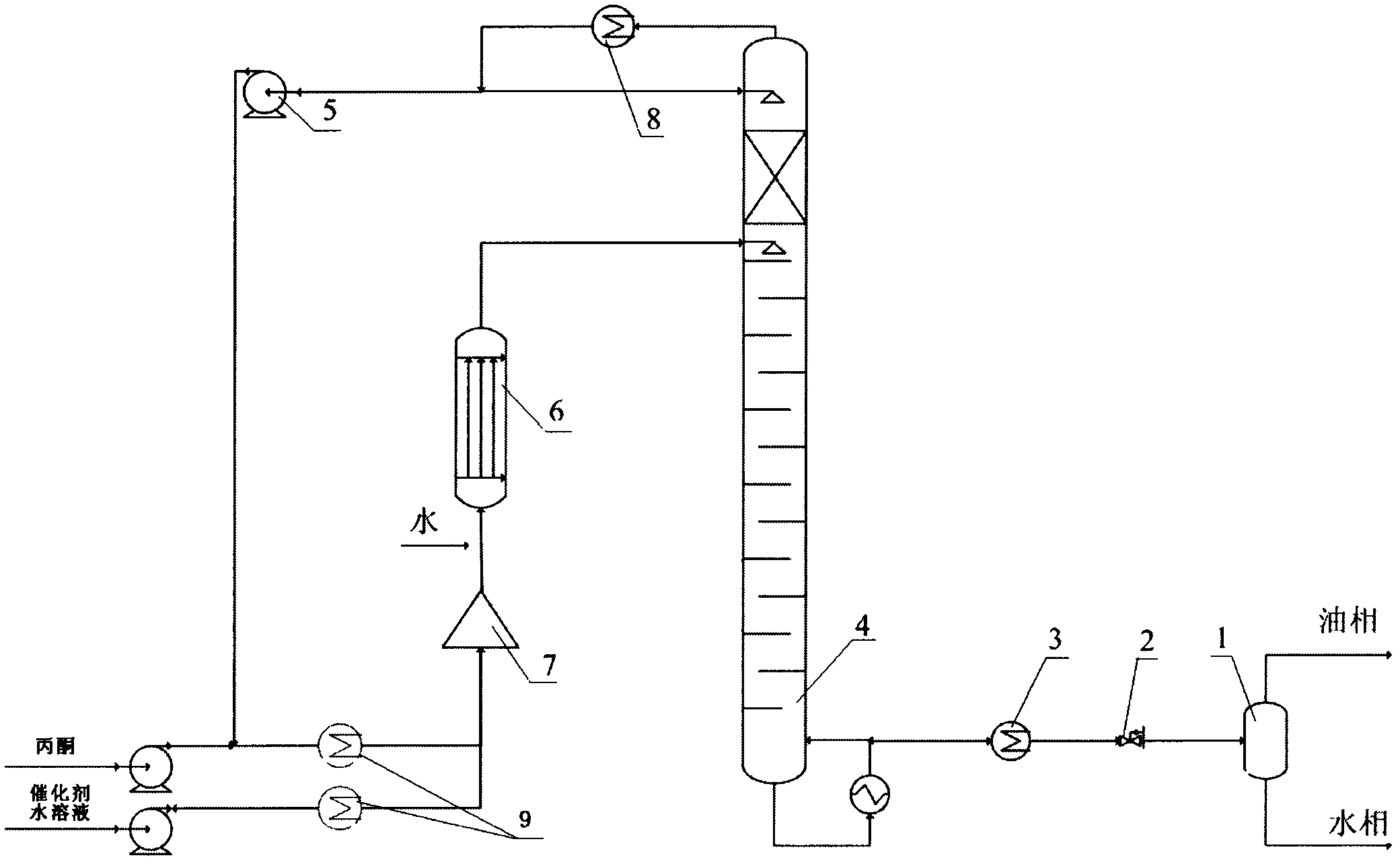

[0032] according to figure 1 The technological process, under continuous steady-state operating conditions, fresh acetone is heated to 230 ℃ through heat exchanger 9 with the flow rate of 100kg / h and the reclaimed acetone (mainly acetone, other about 18wt%) of rectification step from the back , and then preheated to the same temperature, flow rate 38kg / h, KOH aqueous solution with a concentration of 1.8% enters the mixer 7 and mixes fully. After mixing, the mass flow ratio of acetone and water is about 4: 1, and KOH is in the total mixture. The mass fraction is about 0.1%. The mixer adopts SV-type high-efficiency static mixer with a pipe diameter of 20mm and a length of 1m. The residence time of the reaction liquid in the mixer is 15s. The acetone conversion rate is 2% through gas chromatography analysis. Then the reaction solution enters the microchannel reactor 6 produced by Wanhua Polyurethane Company to react. The channel cross section is circular, the inner diameter of t...

Embodiment 2

[0034] according to figure 1 The technological process, under continuous steady-state operating conditions, after fresh acetone is mixed with the reclaimed acetone (mainly acetone, about 18wt% of water) from the rectification step behind with the flow rate of 100kg / h, it is pre-heated by heat exchanger 9 Heat to 280°C, and then fully mix with the KOH solution with a flow rate of 12kg / h and a concentration of 5.0% that is preheated to the same temperature through the mixer 7. At this time, the mass ratio of acetone and water is about 5:1, and KOH is in the total mixture. The mass fraction in is 0.12%. The mixer adopts SV type high-efficiency static mixer with a pipe diameter of 20mm and a length of 1m, and the residence time of the reaction liquid in the mixer is 3s. Then the reaction solution enters the microchannel reactor 6 produced by Wanhua Polyurethane Company for reaction. The inner diameter of the microchannel is 1.5 mm, the number of channels is 1200, the reaction tem...

Embodiment 3

[0036] according to figure 1 The technical process, under continuous steady-state operating conditions, fresh acetone is mixed with reclaimed acetone (mainly acetone, about 18% by weight of water) from the rectification step behind with the flow rate of 100kg / h after fresh acetone is preheated through heat exchanger 9 Heat to 250°C, then fully mix with the KOH solution that is preheated to the same temperature and have a flow rate of 13kg / h and a concentration of 3.2% through the mixer 7. The mass ratio of the mixed acetone and KOH solution is about 5: 1, and KOH is in the The mass fraction in the total mixture is about 0.08%. The mixer adopts SV-type high-efficiency static mixer, with a pipe diameter of 10mm, a pipe number of 30, and a length of 10m. The residence time of the reaction solution in the mixer is 1min. The acetone conversion rate is 6% through gas chromatography analysis, and then the reaction solution is mixed with a 120kg Enter the microchannel reactor 6 that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com