Method for moving and transferring nanowire by using micron-diameter tapered hair

A nanowire, tapered technology used in the field of in situ nanomechanical testing and characterization by scanning electron microscopy and transmission electron microscopy. Problems such as wrong loops to achieve the effect of avoiding pollution and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

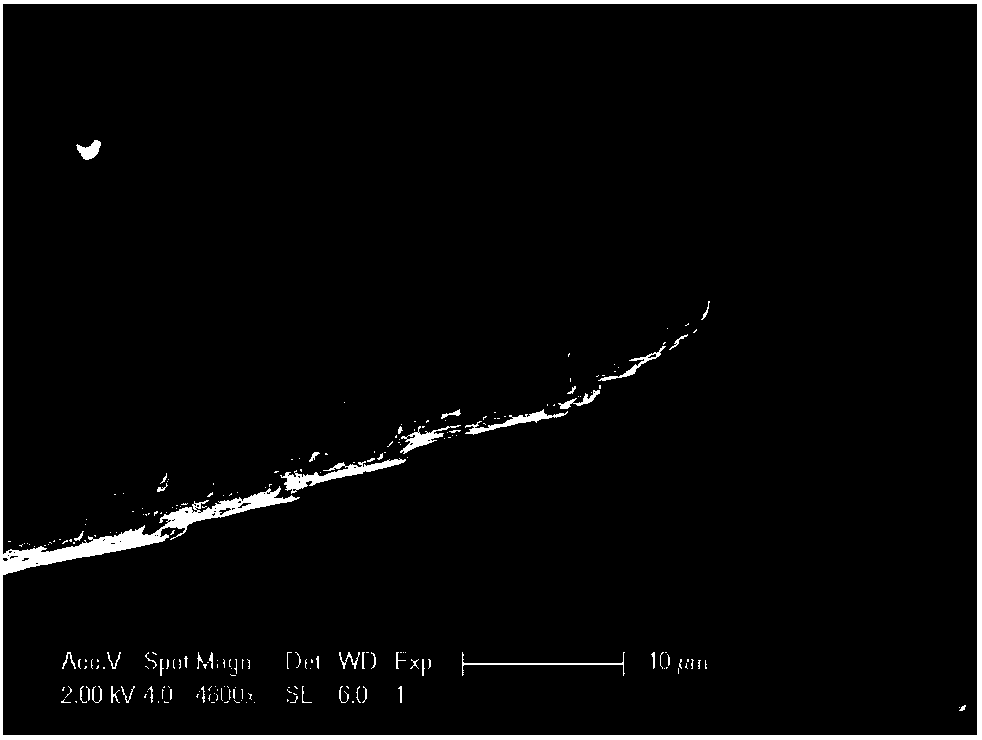

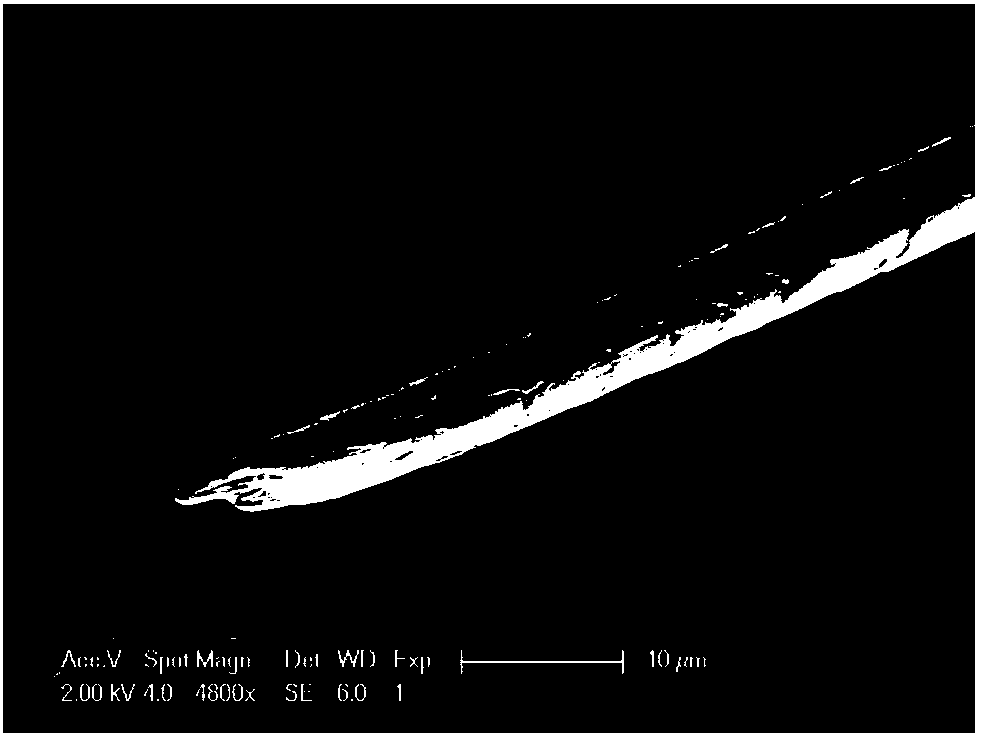

[0032] Select silicon carbide single crystal nanowires with a diameter of 80-100nm as the operation object, use human eyebrows and wool brushes respectively, such as figure 1 As shown, the Langhao brush, such as figure 2Shown as cone-shaped hairs of micron diameter. The diameters of these three cone-shaped hairs range from 2-100 μm, the tip curvature radius is 1-3 μm, and the length is 6-10 mm. Select a 200-mesh copper grid with a diameter of 3mm for the preparation of a TEM sample with a plastic film, burn the plastic film on the copper grid with a lighter, and expose the through hole on the copper grid with a diameter of 90-100 μm. The nanowires were ultrasonically dispersed in acetone for 1.5-2 min. Use tweezers to clamp the copper mesh after removing the film, and ultrasonically clean it in acetone solution for 40-60s to remove traces and pollution after fire. Then take out the copper grid, clamp the copper grid with tweezers, pick up the nanowires in the nanowire solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com