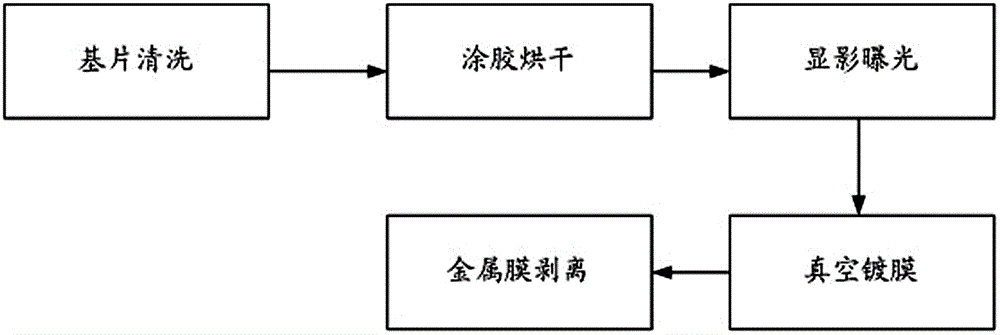

An automatic liquid replenishment system for metal film peeling and cleaning equipment

A technology for cleaning equipment and metal films, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as harmful gas volatilization, equipment shutdown, etc., to ensure device specifications, improve product quality, and improve equipment operation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

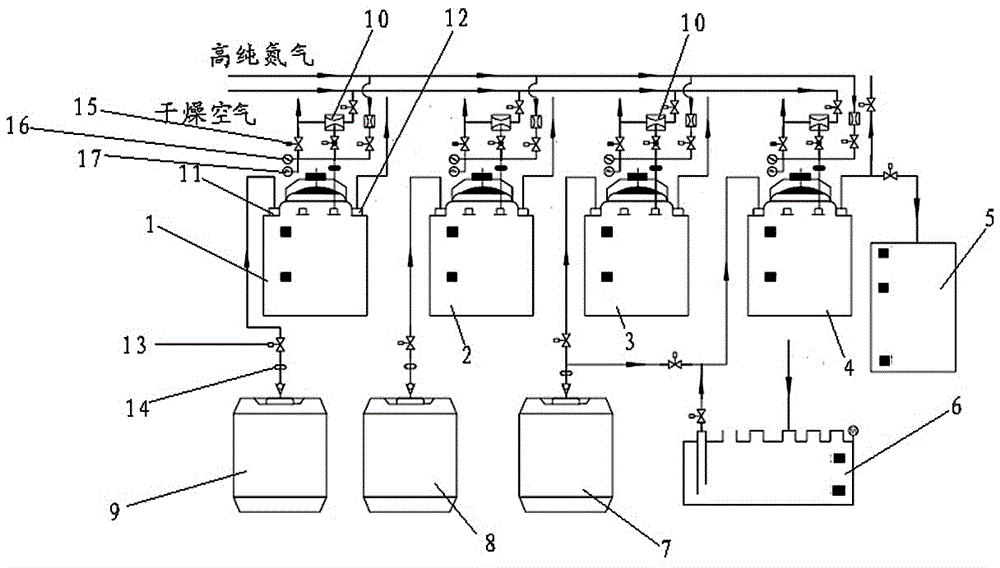

[0025] see figure 2 , which shows the structure of an automatic liquid replenishment system of a metal film stripping cleaning device provided by the present invention. For ease of illustration, only the parts relevant to the present invention are shown.

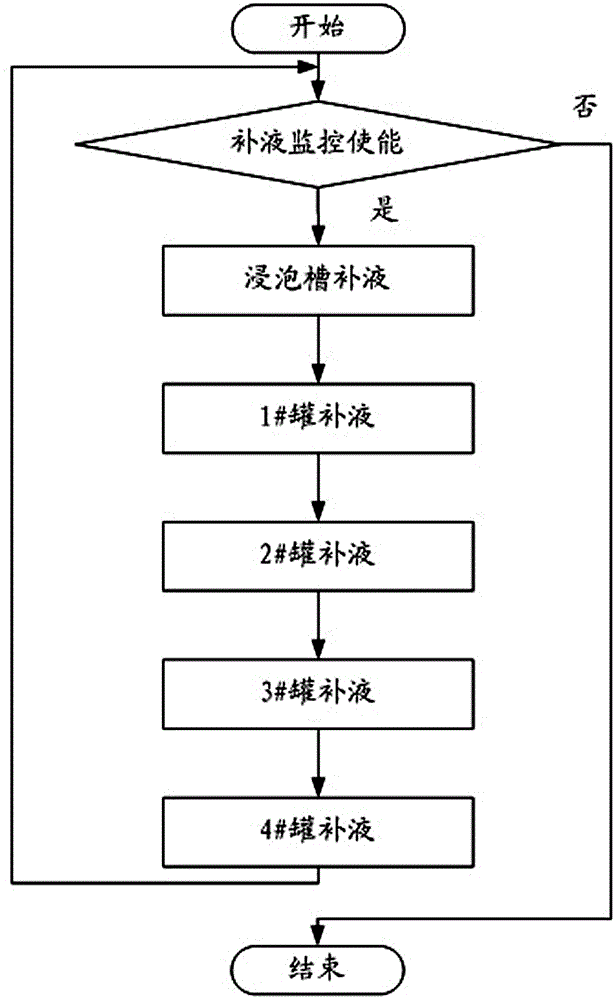

[0026] An automatic liquid replenishment system for metal film peeling and cleaning equipment, comprising an NMP soaking tank 5 and an isopropanol liquid supply pressure tank 1 and an acetone liquid supply pressure tank respectively connected to a vacuum negative pressure differential liquid replenishment device and a nitrogen positive pressure liquid supply device 2. Provide the NMP liquid supply pressure tank 3 for NMP liquid to the NMP soaking tank 5; The liquid replenishment pipe correspondingly connects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com