Preparation method of graphene film

A graphene film and film technology, applied in graphene, nano-carbon and other directions, can solve the problems of waste of resources, complicated preparation process of graphene wave film, human and environmental damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

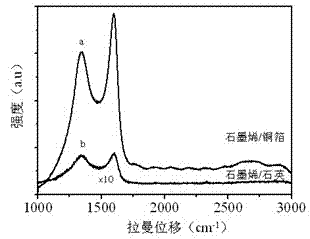

Embodiment 1

[0021] A kind of preparation method of graphene thin film, specifically comprises the steps:

[0022] (1) Dissolve polymethyl methacrylate in acetone solution to form a polymethyl methacrylate acetone solution with a concentration of 3g / L, and then control the polymethyl methacrylate acetone solution with a concentration of 3g / L The dropping speed rate is 0.2ml / min and dripped on the metal sheet to form a polymethyl methacrylate film with a thickness of 100-500nm;

[0023] Described metal sheet is the copper foil that thickness is 0.2mm;

[0024] The metal flakes were cleaned with dilute hydrochloric acid, acetone, ethanol, and deionized water for 10 minutes in order to remove impurities such as oxides and oil stains on the surface of the metal flakes;

[0025] The quartz glass slides are successively cleaned with acetone, ethanol, and deionized water in an ultrasonic cleaner for 10 minutes to remove impurities on the surface of the quartz glass slides;

[0026] (2) Cover th...

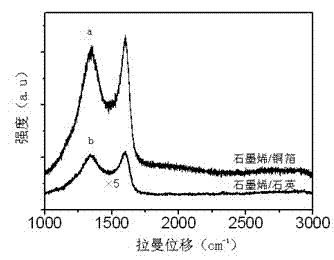

Embodiment 2

[0029] A kind of preparation method of graphene thin film, specifically comprises the steps:

[0030] (1) Dissolve polymethyl methacrylate in acetone solution to form a polymethyl methacrylate acetone solution with a concentration of 3g / L, and then control the polymethyl methacrylate acetone solution with a concentration of 3g / L The dropping speed rate is 0.2ml / min and dripped on the metal sheet to form a polymethyl methacrylate film with a thickness of 100-500nm;

[0031] Described metal sheet is the copper foil that thickness is 0.2mm;

[0032] The metal flakes were cleaned with dilute hydrochloric acid, acetone, ethanol, and deionized water for 10 minutes in order to remove impurities such as oxides and oil stains on the surface of the metal flakes;

[0033] The quartz glass slides are successively cleaned with acetone, ethanol, and deionized water in an ultrasonic cleaner for 10 minutes to remove impurities on the surface of the quartz glass slides;

[0034] (2) Cover th...

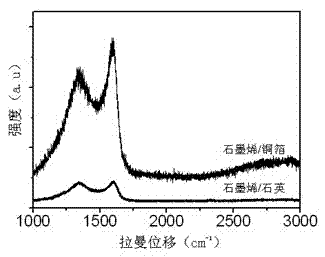

Embodiment 3

[0037] A kind of preparation method of graphene thin film, specifically comprises the steps:

[0038] (1) Dissolve polymethyl methacrylate in acetone solution to form a polymethyl methacrylate acetone solution with a concentration of 3g / L, and then control the polymethyl methacrylate acetone solution with a concentration of 3g / L The dropping speed rate is 0.2ml / min and dripped on the metal sheet to form a polymethyl methacrylate film with a thickness of 100-500nm;

[0039] Described metal sheet is the copper foil that thickness is 0.2mm;

[0040] The metal flakes were cleaned with dilute hydrochloric acid, acetone, ethanol, and deionized water for 10 minutes in order to remove impurities such as oxides and oil stains on the surface of the metal flakes;

[0041] The quartz glass slides are successively cleaned with acetone, ethanol, and deionized water in an ultrasonic cleaner for 10 minutes to remove impurities on the surface of the quartz glass slides;

[0042] (2) Cover th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com