Method for preparing silicon-aluminum-iron alloy containing nano-particles by using nano-molten salt

A nanoparticle and ferroalloy technology, applied in the direction of improving process efficiency, can solve the problems of increasing the production cost and preparation cost of nanoparticle-containing steel, and achieve the effect of increasing added value and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

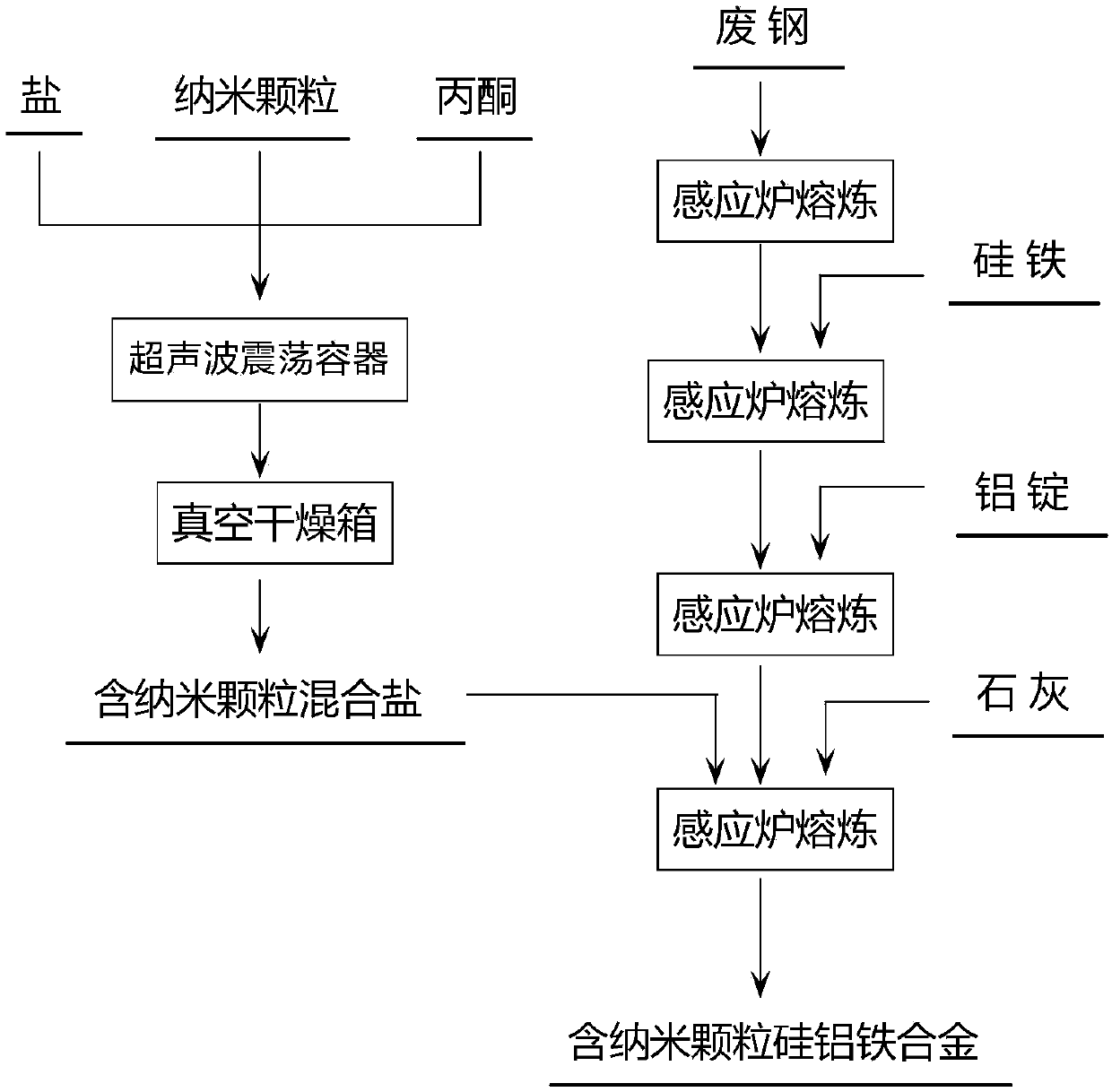

Image

Examples

Embodiment 1

[0025] Mechanically mix titanium carbide nanoparticles with a particle size of 30-50 nanometers with salt, the composition of which is: NaCl: 15%, KCl: 15%, NaCl 3 AlF 6 : 70%, the weight of titanium carbide nanoparticles is 0.25 of the salt, the mixed nanoparticle-containing salt and the acetone liquid whose mass is 4 times that of the nanoparticle-containing salt are added to the ultrasonic vibrator, and after ultrasonic vibration treatment for 2 hours, the dispersed The acetone solution in which the nanoparticles are distributed is placed in a vacuum drying oven and heated in a vacuum with a vacuum degree of 0.06 MPa and a vacuum heating temperature of 190°C; heat treatment in vacuum for 2 hours to obtain a mixed salt in which the nanoparticles and the salt are evenly distributed. Add scrap steel, No. 75 ferrosilicon, aluminum ingots in sequence, and then add the latter material after the former material is melted. After the alloy is completely melted, add mixed salt and li...

Embodiment 2

[0027] Mechanically mix titanium nitride nanoparticles with a particle size of 40-70 nanometers and salt, the composition of the salt is: NaCl: 17%, KCl: 19%, Na3AlF6: 64%; the weight of titanium nitride nanoparticles is the salt 0.3, add the mixed nanoparticle-containing salt and the acetone liquid whose mass is 5 times that of the nanoparticle-containing salt into the ultrasonic vibrator, and after ultrasonic vibration treatment for 2.5 hours, put the acetone solution with dispersed nanoparticles into a vacuum drying oven Vacuum heating in medium, the vacuum degree is 0.07 MPa, and the vacuum heating temperature is 170°C; after vacuum heating for 1.8 hours, a mixed salt with uniform distribution of nanoparticles and salt is obtained; in the induction furnace, scrap steel, No. 75 ferrosilicon, For aluminum ingots, add the latter material after the former material is melted. After the alloy is completely melted, add mixed salt containing nanoparticles and lime; the weights of ...

Embodiment 3

[0029] Mechanically mix the zirconium boride nanoparticles with a particle size of 40-80 nanometers and the salt, the composition of the salt is: NaCl: 20%, KCl: 18%, Na3AlF6: 62%, and the weight of the zirconium boride nanoparticles is the salt 0.32; the mixed nanoparticle-containing salt and the acetone liquid whose mass is 6 times that of the nanoparticle-containing salt are added to the ultrasonic vibrator, and after ultrasonic vibration treatment for 2.3 hours, the acetone solution with dispersed nanoparticles is put into a vacuum drying oven Medium vacuum heating, the vacuum degree is 0.04 MPa, and the vacuum heating temperature is 160°C; the vacuum heating treatment is completed after 1.5 hours, and the mixed salt with uniform distribution of nanoparticles and salt is obtained; scrap steel and No. 75 ferrosilicon are sequentially added into the induction furnace , aluminum ingots, after the former material is melted, add the latter material; after the alloy is completely...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com