High-temperature-resisting conveying belt of steel wire rope

A steel wire rope core, high temperature resistant technology, used in conveyors, transportation and packaging, etc., can solve the problems of safe and economical transportation of high temperature materials, and can solve the problem of degumming, improve heat resistance temperature and service life, and high heat resistance temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

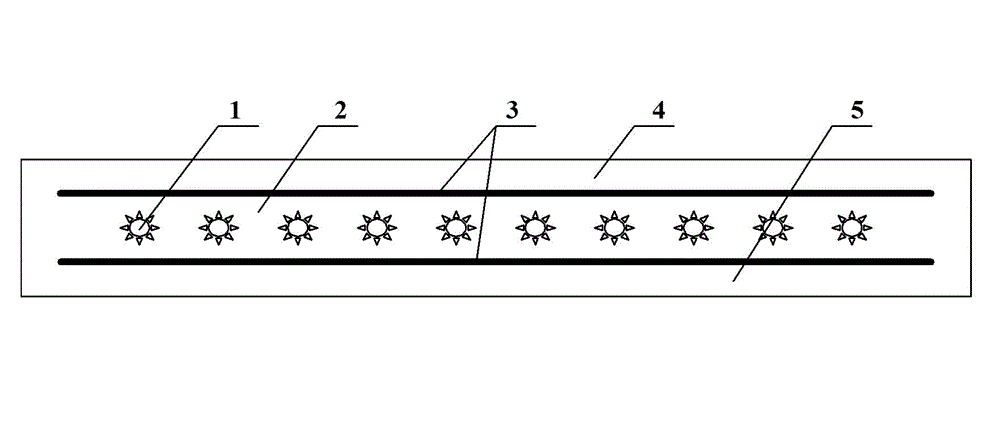

[0013] The steel cord high temperature resistant conveyor belt of the present invention comprises a steel cord core 1, an intermediate rubber layer 2, an upper covering rubber layer 4, and a lower covering rubber layer 5, wherein:

[0014] The upper cover rubber layer 4 and the lower cover rubber layer 5 are high temperature resistant vulcanized rubber, and the rubber material formula is: 70 parts of EPDM rubber, 30 parts of chlorosulfonated polyethylene rubber, diisopropyl peroxide 6 parts of benzene, 1 part of sulfur, 10 parts of zinc oxide, 2 parts of ethylene dimethacrylate, 2 parts of stearic acid, 2 parts of accelerator dibenzothiazole disulfide, accelerator tetramethylthiuram disulfide 2 parts, anti-aging agent 2,2,4-trimethyl-1,2-dihydroquinoline, 2 parts, anti-aging agent N-phenyl-β-naphthylamine 2 parts, paraffin oil 15 parts, high wear-resistant carbon 30 parts of black, 30 parts of semi-reinforcing carbon black, 10 parts of active glass fiber powder.

[0015...

Embodiment 2

[0017] The steel cord high temperature resistant conveyor belt of the present invention comprises a steel cord core 1, an intermediate rubber layer 2, an upper covering rubber layer 4, and a lower covering rubber layer 5, wherein:

[0018] The upper cover rubber layer 4 and the lower cover rubber layer 5 are high temperature resistant vulcanized rubber, and the rubber material formula is by weight: 80 parts of EPDM rubber, 20 parts of chlorosulfonated polyethylene rubber, diisopropyl peroxide 7 parts of benzene, 1 part of sulfur, 12 parts of zinc oxide, 2 parts of ethylene dimethacrylate, 2 parts of stearic acid, 1.5 parts of accelerator 2-mercaptobenzothiazole, accelerator diethyldithioamino 2 parts of zinc formate, 1 part of zinc dibutyl dithiocarbamate accelerator, 2 parts of anti-aging agent 2,2,4-trimethyl-1,2-dihydroquinoline, 20 parts of paraffin oil, high resistance 25 parts of ground carbon black, 40 parts of semi-reinforcing carbon black, and 12 parts of active...

Embodiment 3

[0022] The steel cord high temperature resistant conveyor belt of the present invention comprises a steel cord core 1, an intermediate rubber layer 2, an upper covering rubber layer 4, and a lower covering rubber layer 5, wherein:

[0023] The upper cover rubber layer 4 and the lower cover rubber layer 5 are high temperature resistant vulcanized rubber, and the rubber material formula is: 75 parts of EPDM rubber, 25 parts of acrylate rubber, 7.5 parts of dicumyl peroxide , 0.5 parts of sulfur, 11 parts of zinc oxide, 2 parts of ethylene dimethacrylate, 2 parts of stearic acid, 1 part of accelerator dibenzothiazole disulfide, 2 parts of zinc dibutyldithiocarbamate, 2 parts - 2 parts of thiol benzothiazole, 1 part of tetramethylthiuram disulfide, 1 part of anti-aging agent 2,2,4-trimethyl-1,2-dihydroquinoline, anti-aging agent N-phenyl - 1 part of β-naphthylamine. 20 parts of paraffin oil, 30 parts of high wear-resistant carbon black, 35 parts of semi-reinforcing carbon b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com