Patents

Literature

56 results about "Ethylene dimethacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and application for Mn-doped ZnS quantum-dot surface imprinting fluorescent probe

ActiveCN105237677AEasy to removeImprove bindingOther chemical processesFluorescence/phosphorescenceFluoProbesFunctional monomer

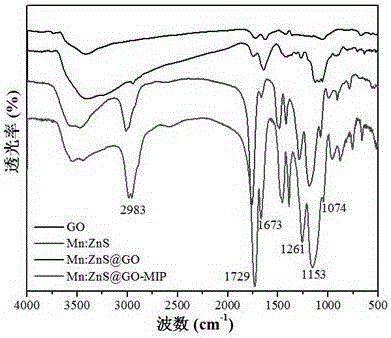

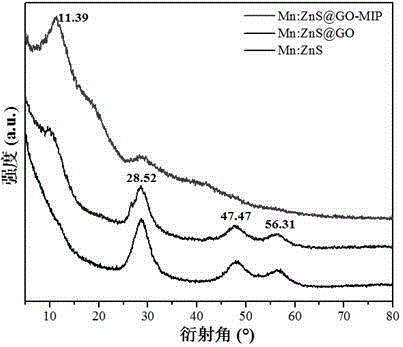

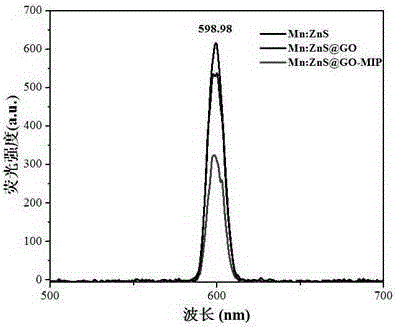

The invention relates to a preparation method and application for a Mn-doped ZnS quantum-dot surface imprinting fluorescent probe, and belongs to the technical field of preparation of environment functional materials. By utilizing a free radical polymerization method and taking propionamide as a molecular imprinting polymer dummy template, methacrylic acid (MAA) as a functional monomer, Mn-doped ZnS quantum dot graphene oxide (Mn:ZnS@GO) as a matrix material, ethylene dimethacrylate (EGDMA) as a cross-linking agent, azodiisobutyronitrile (AIBN) as an initiator and N,N-dimethyl formamide (DMF) as a solvent, the surface imprinting fluorescent probe is synthesized and is used for enriching detection on acrylamide in food. The fluorescent probe prepared by employing the method embodiments advantages of surface molecular imprinting, avoids the molecule embedding excessive-deep problem of a molecular imprinting polymer template prepared by employing a conventional method, improves identification efficiency and combination speed, and also gives consideration to advantages of high luminescence efficiency, fast fluorescence attenuation and the like of the doped quantum dot, and improves detection rate and sensitivity.

Owner:JIANGSU UNIV

Nano waterproof paint

ActiveCN103555090AImprove waterproof performanceStrong scrub resistanceCoatingsAcrylic resinMetasilicate

The invention discloses a nano waterproof paint, which is prepared by the raw materials by weight: 70-80 parts of polyvinyl acetate emulsion, 3-5 parts of potassium metasilicate, 2-4 parts of lithium silicate, 8-10 parts of potassium titanate whisker, 5-7 parts of aqueous self-drying organosilicon modified acrylic resin HA88405, 15-20 parts of nanometer powdered carbon, 2-3 parts of nano zinc oxide, 3-5 parts of oxidation starch, 1-2 parts of urea, 1-2 parts of actinolite powder, 2-3 parts of ethylene dimethacrylate, 7-10 parts of bonding auxiliary agent, and 10-20 parts of deionized water. The waterproof paint has good waterproof paint, strong scrub resistance, and good stain resistance, and also has certain anticorrosion and sterilization efficacies, and good comprehensive properties.

Owner:湖南亚仕龙建材商贸有限公司

Preparation of molecular imprinting polymer and method for separating clenobuterol hydrochloride by using the same

InactiveCN101434679AAchieve removalWith "memory" functionAmino compound purification/separationOther chemical processesPolymer scienceSolvent

The invention relates to the preparation of molecular imprinted polymer in the technical field of chemical engineering and a method for separating clenbuterol hydrochloride with the molecular imprinted polymer. In the preparation method, clenbuterol, methacrylic acid, ethylene dimethacrylate are mixed according to the mol ratio of 1: 2-6: 15, dissolved in a pore-foaming agent, placed in an ampoule, added with an initiator, processed by ultrasonic wave, fed in nitrogen, sealed in vacuum, and then carried out thermal-initiated polymerization so as to obtain bulk polymer; and the bulk polymer is taken out, crushed, sieved and separated; after the polymer is dried, soxhlet extraction, high-temperature processing and solvent elution are carried out to get rid of a template. In the separation method, the molecular imprinted polymer homogenate is filled in a small column of polypropylene solid phase extraction, and the upper and lower ends of the filling material are respectively added with a sieve plate of polyethylene and the filling material is pressed tightly; and the small column of solid phase extraction is activated, leached and eluted so as to collect clenbuterol hydrochloride. The molecular imprinted polymer prepared by the method has high selectivity and specificity, can resist to unfriendly environment and combine with ELISA in use.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing apiolin molecularly imprinted polymer

InactiveCN101665551AHigh affinityImprove adsorption capacityOther chemical processesFunctional monomerPolymer science

The invention relates to a method for preparing an apiolin molecularly imprinted polymer, comprising the following steps: dissolving apiolin and a functional monomer of 1 mol fraction of template molecule according to the mole ratio of 1:4-1:10 in 40 parts by volume of butylene oxide of a pore-foaming agent; vibrating away from light at constant temperature for 6h; then adding ethylene dimethacrylate as a crosslinking agent, the amount of which is 4-7 times of that of the monomer, and azodiisobutyronitrile as an initiating agent, the quality of which is 1 percent of that of the monomer and thecrosslinking agent, and completely mixing; sealing after N2 is introduced to remove oxygen; carrying out thermal-initiated polymerization at the temperature of 40-60 DEG C for 24-48h, and then obtaining a rod-shaped solid polymer; rubbing and then sieving the polymer; utilizing a methanol / acetic acid (v / v=6:4) eluent to elute so as to remove the template molecule; putting in a vacuum drying cabinet and then drying until constant weight, and then obtaining the apiolin molecularly imprinted polymer. The apiolin molecularly imprinted polymer prepared by the method has specific identification ability and selective adsorption performance on apiolin. Compared with common sorbents, the polymer has the advantages of accuracy, rapidness and sensitivity. Moreover, the polymer has high percent recovery, good repeatability and long service life, thereby having wide application prospects.

Owner:JIANGSU UNIV

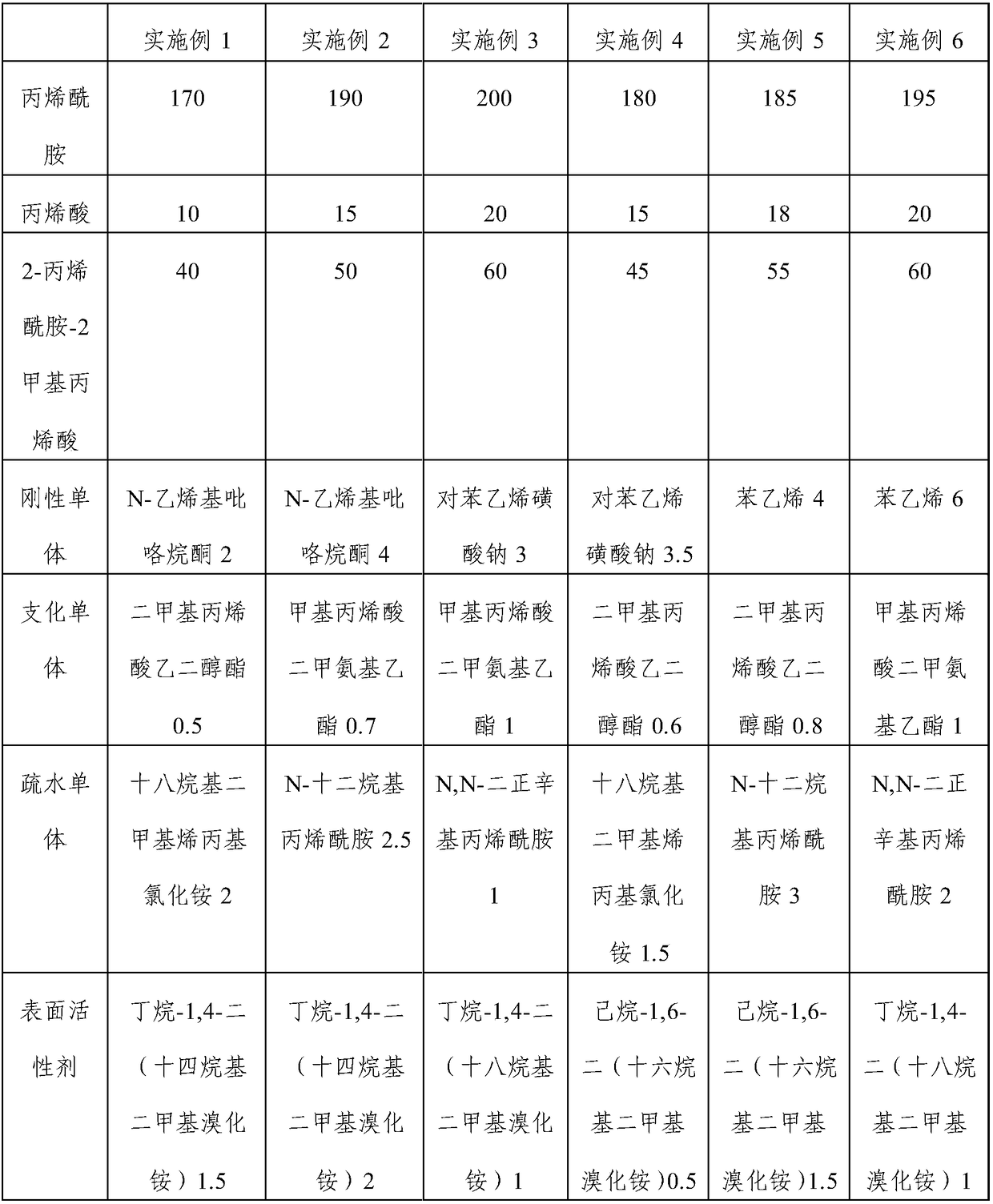

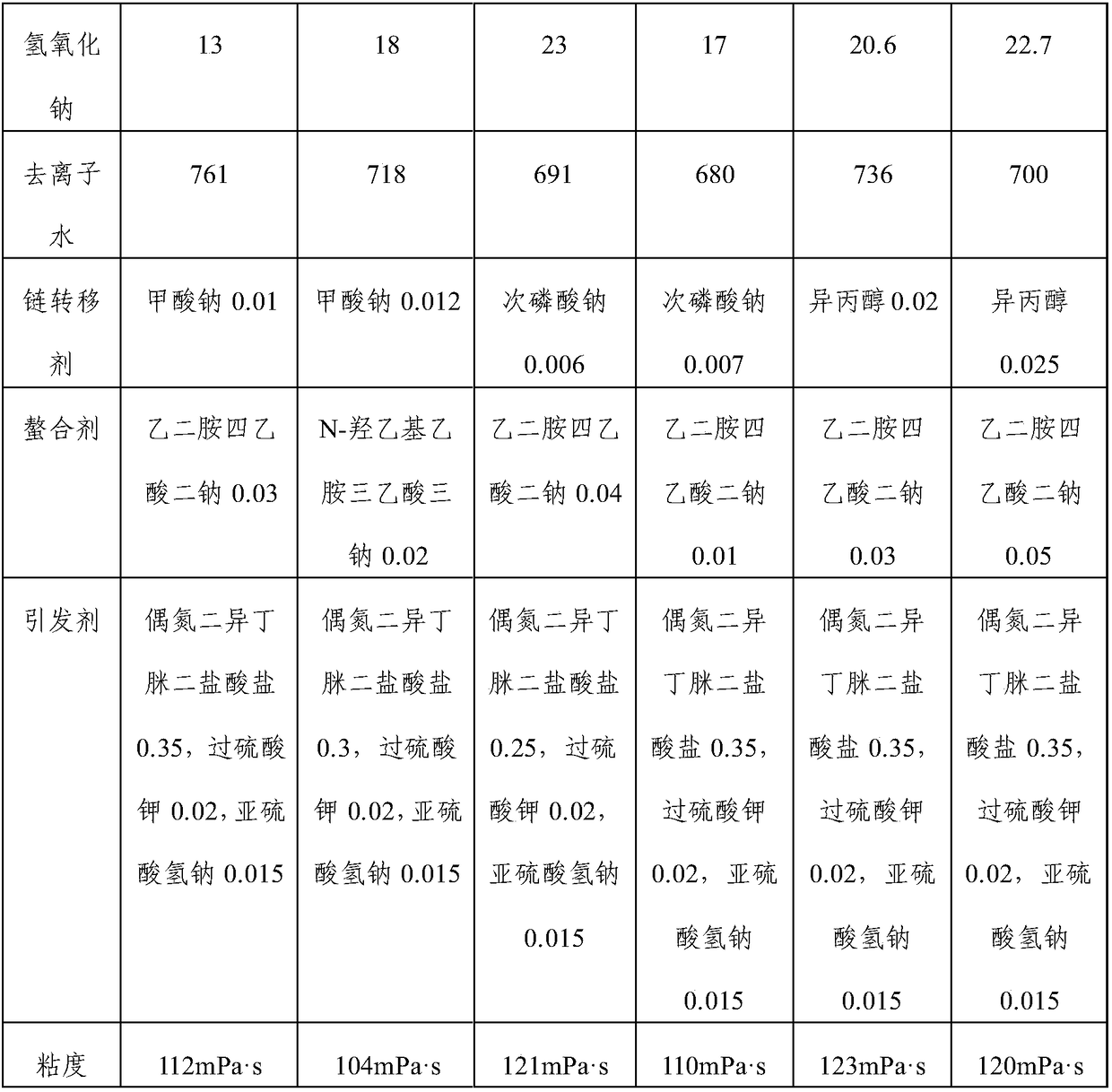

Micro-branched micro-cross-linked association polymer, preparation method and applications thereof

ActiveCN108264607AGood temperature and salt resistanceEnhance molecular chain rigidityGeneral water supply conservationSolventTemperature resistance

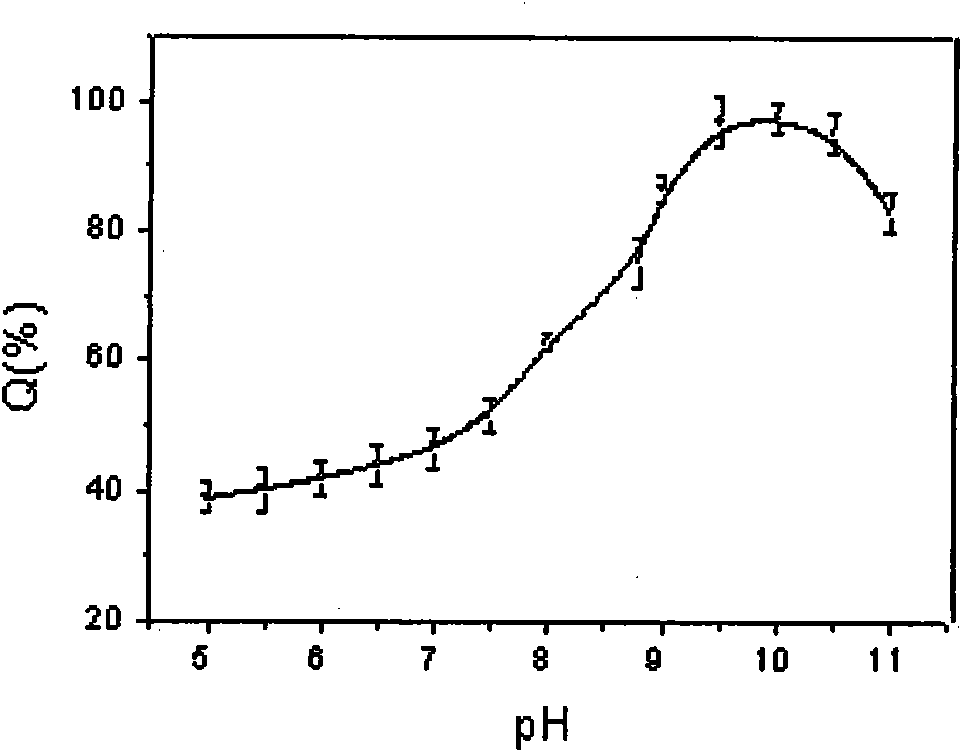

The invention relates to a micro-branched micro-cross-linked association polymer, a preparation method and applications thereof. The preparation method comprises: (1) carrying out initial mixing: mixing acrylamide, acrylic acid, 2-acrylamide-2-methyl propanesulfonic acid, a rigid monomer, a branched monomer, a hydrophobic monomer, a surfactant and a solvent, wherein the rigid monomer is any one ora variety of materials selected from N-vinylpyrrolidone, styrene and sodium p-styrenesulfonate, the branched monomer is ethylene dimethacrylate and / or 2-(dimethylamino)ethyl methacrylate, and the hydrophobic monomer is any one or a variety of materials selected from N,N-di-n-octyl acrylamide, N-dodecyl acrylamide and octadecyl dimethylallyl ammonium chloride; (2) adjusting the pH value by addingan alkali; (3) adding an auxiliary agent; and (4) polymerizing: adding an initiator to the mixed solution treated in the step (3), and initiating a polymerization reaction so as to obtain the micro-branched micro-cross-linked association polymer, wherein the obtained micro-branched micro-cross-linked association polymer has excellent temperature resistance and excellent salt resistance.

Owner:SHANDONG NUOER BIOLOGICAL TECH

Preparation method and application of ZnS quantum dot silica-based surface molecular imprinting sensor

The invention provides a preparation method and application of a ZnS quantum dot silica-based surface molecular imprinting sensor, belonging to the technical field of environmental function material preparation. The preparation method comprises the following steps: hydrolyzing silicon tetraacetate in a mixed solution of alkaline ethanol and water to prepare SiO2, and meanwhile adding a water solution of sodium sulphide hydrate in the water solution of zinc sulfate heptahydrate and tetrahydrate manganese chloride to prepare Mn-ZnS quantum dot; then respectively performing vinyl modification on the obtained SiO2 and Mn-ZnS quantum dot by using 3-methacryloxypropyltrimethoxysilane; and synthesizing the quantum dot phosphorescence surface molecular imprinting polymer through a precipitation polymerization method by using 2,4-dichlorophenol as a template molecule, acrylamide as functional monomer, Mn-ZnS-KH570 as an auxiliary monomer, SiO2-KH570 as a host material, ethylene dimethacrylate as a cross-linking agent, 2,2'-azobis(2-methylpropionitrile) as an initiator, and acetonitrile as solvent. The prepared phosphorescence surface molecular imprinting polymer has good optical and pH stability and has the capability of selectively recognizing 2,4-dichlorophenol.

Owner:JIANGSU UNIV

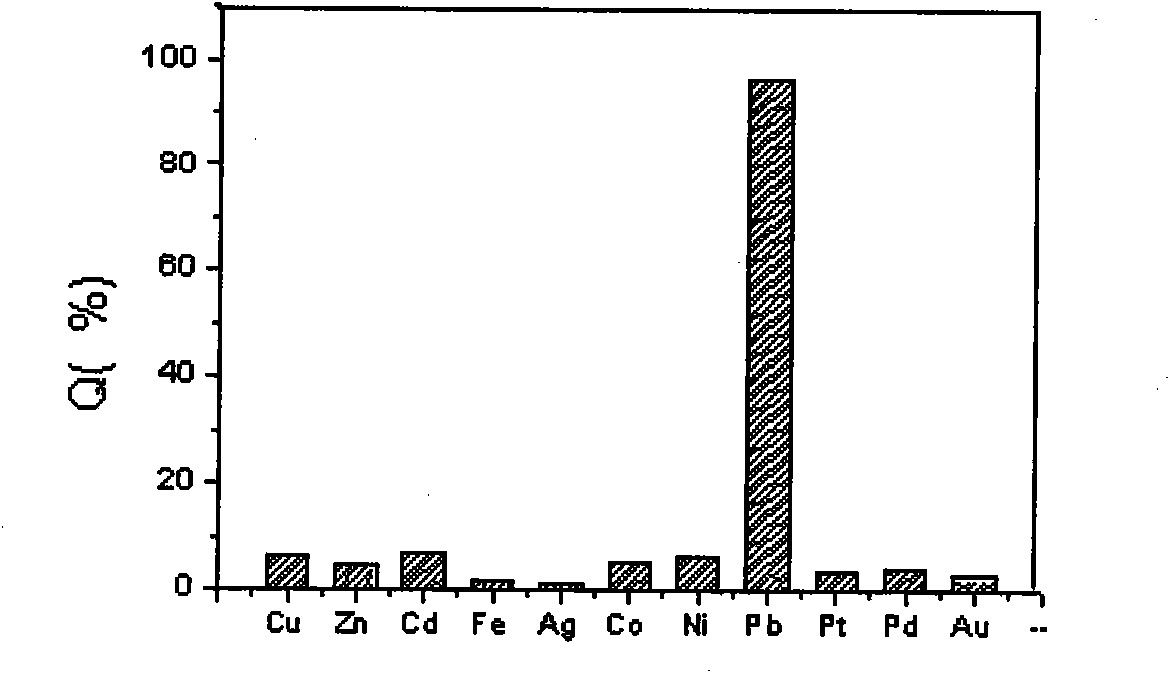

Preparation method of blotting membrane for Hg<2+> detection

InactiveCN103087346AHigh selectivityHigh sensitivityFluorescence/phosphorescenceEthylene dimethacrylatePolyvinylidene difluoride

The invention discloses a preparation method of a blotting membrane for Hg<2+> detection. The preparation method comprises the following steps: designing and synthesizing Rhodamine derivative with special developing function to Hg<2+>; and opolymerizing on a support polyvinylidene fluoride membrane by using target metal ion as a template, ethylene dimethacrylate as a crosslinking agent, azodiisobutyronitrile as a radical initiator, and the synthesized Rhodamine derivative as a function monomer to obtain the blotting membrane for mercury ion detection. The characteristic that the ionic blotting technology has high selectivity to the template ion is adopted by the invention to combine with the simplicity of a colorimetric / fluorescence chemical sensor, a colorimetric / fluorescence chemical sensing blotting membrane with high selectivity to Hg<2+> is prepared, and a fast and high-speed new scene detection method with high sensitivity and high selectivity is hopefully provided for heavy metal ions in environment and food.

Owner:WENZHOU INST OF TECH TESTING & CALIBRATION

Preparation method and use of loofah sponge surface lead ion imprinted absorbing material

InactiveCN101992067ASpecific recognition abilityHigh selectivityOther chemical processesWater/sewage treatment by sorptionWater bathsHigh absorption

The invention discloses a preparation method of a loofah sponge surface lead ion imprinted absorbing material and the use of the loofah sponge surface lead ion imprinted absorbing material in metal ion absorption and belongs to natural high polymer material modification. In the method, the loofah sponge natural high polymer material is used as a support, and the surface of the material is modified with a lead ion imprinted polymer. The main technical characteristics of the method include: adding acylated loofah sponge, lead-dithizone complex, 4-vinylpyridine, ethylene dimethacrylate and azodiisobutyronitrile into a chloroform medium, removing oxygen by argon in a certain proportion; introducing argon to expel oxygen; reacting in a water bath at a constant temperature of 50 to 70 DEG C, filtering and washing; and performing Soxhlet extraction by using 0.10mol / L solution of HNO3 for 12 hours, removing template lead ions, washing, drying and obtaining the material. The material has specific lead ion identification capacity, high selectivity, high absorption speed and high desorption capacity, is widely available and biodegradable, can be prepared by a simple process and has regeneration capacity and the advantages of environmental friendliness and the like.

Owner:UNIV OF JINAN

Preparation method of solid-phase extraction small column for molecular imprinting of substituted carbamide pesticide

InactiveCN101497035AWith dynamic "memory" functionImprove efficiencyOther chemical processesCross-linkFunctional monomer

The invention discloses a method for preparing a molecularly imprinted solid-phase extraction column of substituted urea pesticide, which belongs to the technical field of food safety. The method comprises the following steps: preparing a template molecule substituted urea pesticide, a functional monomer methacrylic acid and a cross-linking agent ethylene dimethacrylate into a molecularly imprinted polymer microsphere of the substituted area pesticide through suspension polymerization according to a mol ratio of the template molecule to the functional monomer to the cross-linking agent of 1:2-8:20; and weighing the molecularly imprinted polymer microsphere of the substituted urea pesticide to be filled in an empty pipe of polypropylene solid-phase extraction column to prepare the molecularly imprinted solid-phase extraction column of the substituted urea pesticide. The molecularly imprinted solid-phase extraction column of the substituted urea pesticide can be used for selective purification and selective enrichment of an extracted solution of a residual sample of the substituted urea pesticide in inspected food and environment. Compared with common liquid-liquid extraction method and C18 solid-phase extraction method, the method has the characteristics of easiness, rapidness, high purification efficiency and the like.

Owner:ANHUI AGRICULTURAL UNIVERSITY

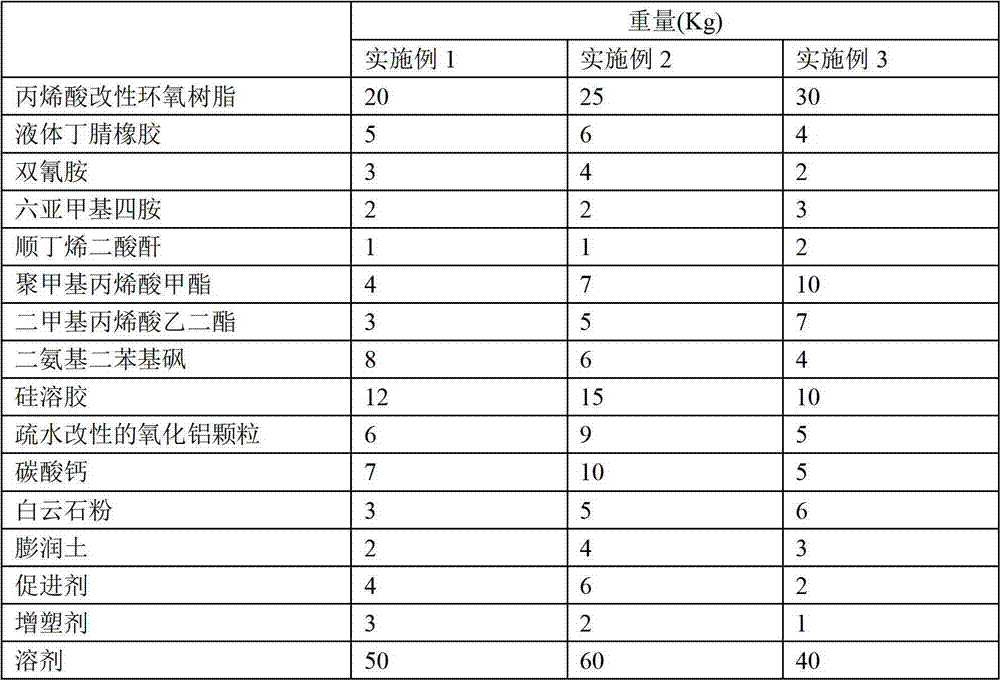

Adhesive for adhering ceramic and metal

InactiveCN102876275AGood adhesionNon-macromolecular adhesive additivesModified epoxy resin adhesivesAdhesiveCis-Butenedioic Acid

The invention provides an adhesive for adhering ceramic and metal, belonging to the technical field of adhesives. The adhesive comprises the following raw materials by weight: 20-30 parts of acrylic-acid modified epoxy resin, 4-6 parts of liquid nitrile rubber, 2-4 parts of dicyandiamide, 2-3 parts of hexamethylene tetramine, 1-2 parts of maleic anhydride, 4-10 parts of polymethyl methacrylate, 3-7 parts of ethylene dimethacrylate, 4-8 parts of diaminodiphenyl sulfone, 10-15 parts of silica sol, 5-9 parts of hydrophobically modified alumina particles, 5-10 parts of calcium carbonate, 3-6 parts of dolomite powder, 2-4 parts of bentonite, 2-6 parts of accelerant, 1-3 parts of plasticizer and 40-60 parts of solvent. The adhesive provided by the invention has good adhering properties, is used for adhering ceramic and metal, has the shearing strength of more than 17MPa or more and has the shearing strength of more than 14Mpa after being damaged in the high-temperature environment.

Owner:WUJIANG TIANYUAN PLASTIC

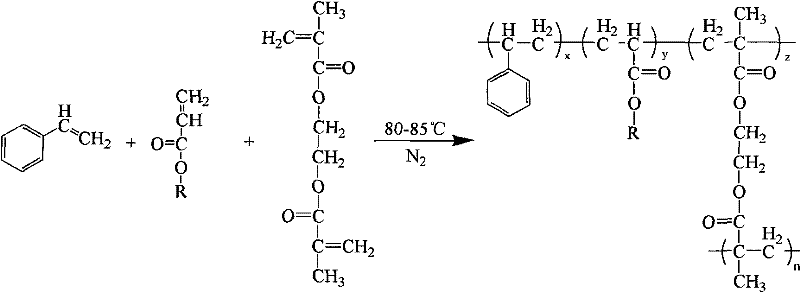

Aqueous plastic-plastic compounding glue water for soft packaging and preparation method thereof

InactiveCN106221623ALow costNo need to increase investmentEster polymer adhesivesWater useAcrylonitrile

The invention provides aqueous plastic-plastic compounding glue water for soft packaging, and relates to compounding glue water. The compounding glue water is prepared from the following ingredients in parts by weight: 20 to 30 parts of acrylic ester monomers, 1 to 5 parts of acrylic acid or methacrylic acid, 2 to 4 parts of alkyl methacrylate esters, 10 to 20 parts of styrene or acrylonitrile, 1 to 2 parts of acrylic acid hydroxyl esters, 0.2 to 1 part of N-Methylol acrylamide or diacetone-acryloamide, 1 to 5 parts of adipic dihydrazide, 0.4 to 0.8 part of itaconic acid, ethylene dimethacrylate or diallyl maleate, 0.3 to 1 part of emulsifying agents, 0.2 to 0.8 part of initiating agents, 0.1 to 0.3 part of buffering agents and 0.3 to 1 part of wetting agents. According to the material structure matching, the dry glue coating quantity per square meter can be controlled to be 0.5 to 2g, and the requirements can be met, for example, thin BOPP / CPP only needs 0.5 kg of dry glue, and the transparency and the firmness degree can reach the requirements; the cost of glue water used in per square meter is as low as 0.02 Yuan RMB; the product can be used on an original dry type compounding machine; the addition of equipment investment is not needed.

Owner:广东佰合新材料科技股份有限公司

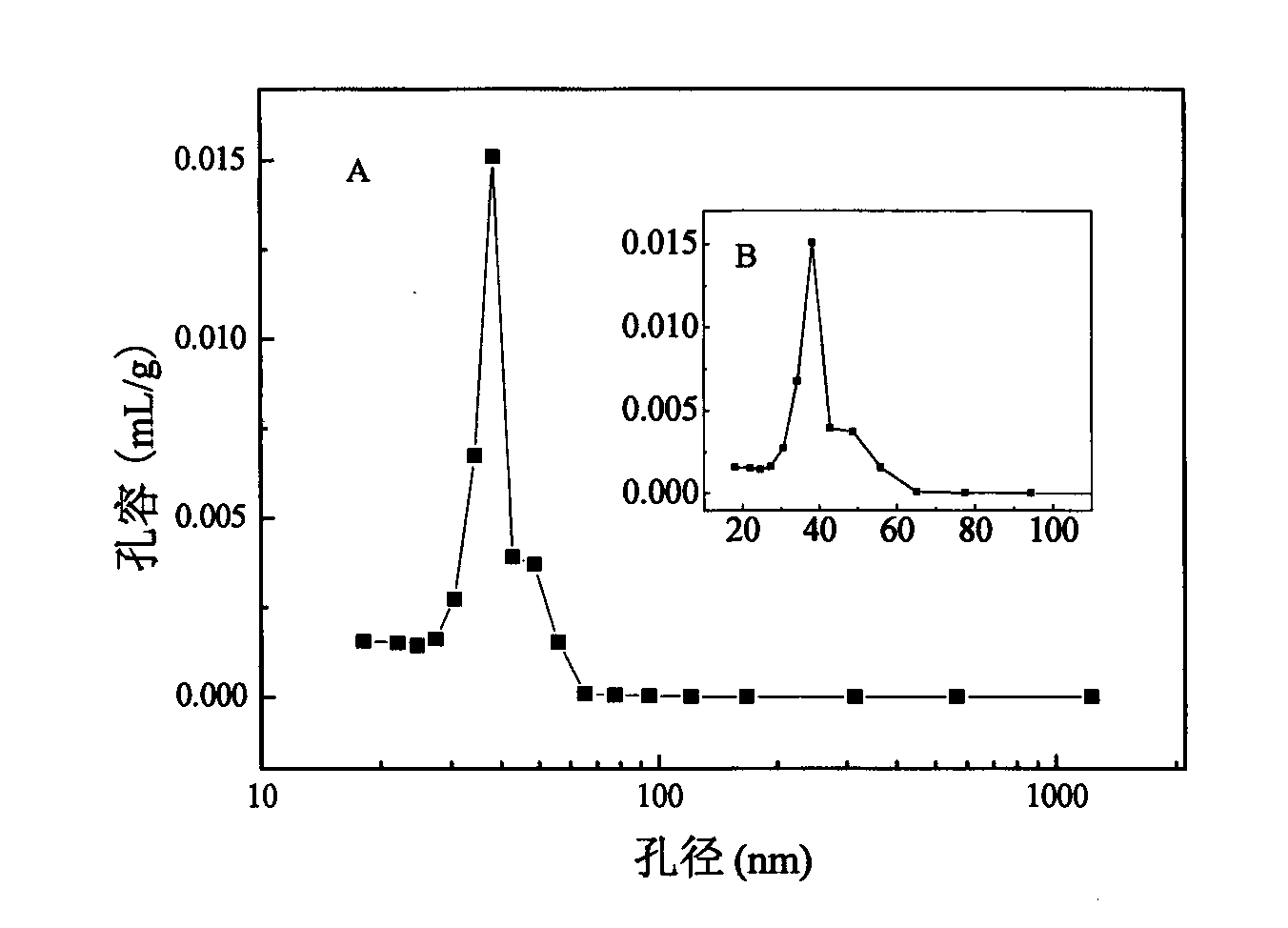

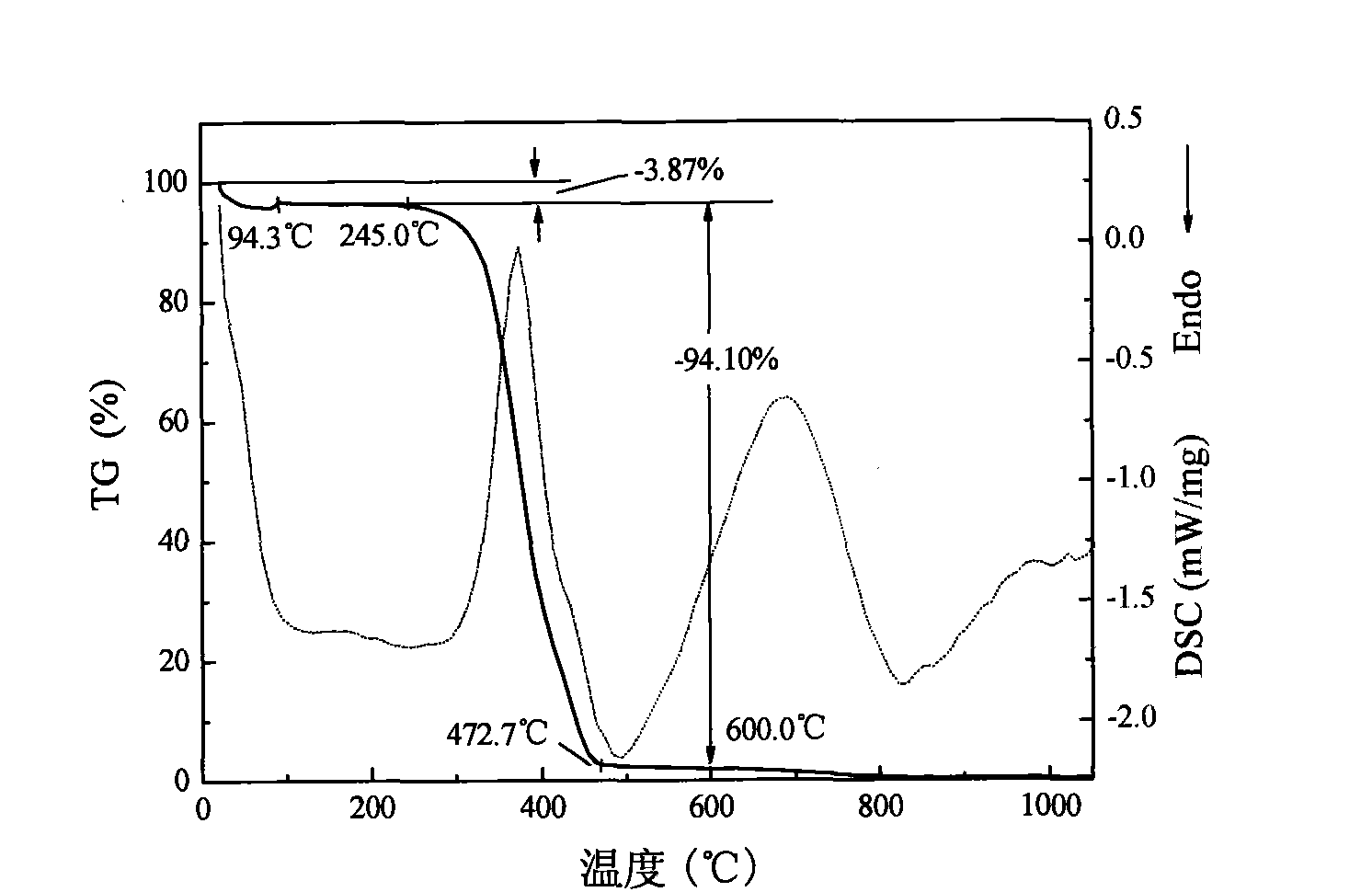

Preparation method of macroporous long alkyl side chain acrylic acid ester-styrene-ethylene dimethacrylate crosslinking copolymerization microballoon

The invention provides a preparation method of macroporous long alkyl side chain acrylic acid ester-styrene-ethylene dimethacrylate crosslinking copolymerization microballoon. The invention relates to macroporous long alkyl side chain acrylic acid ester-styrene-ethylene dimethacrylate crosslinking copolymerization microballoon and a preparation method thereof. In the preparation method, oil-soluble benzoyl peroxide is an initiator, long alkyl side chain acrylic acid ester, styrene and ethylene dimethacrylate are monomers, a suspension polymerization method is employed, an aqueous solution containing a dispersant and salt is water phase, and the monomers containing the initiator and a pore forming agent are mixed as stable oil phase. Under protection of nitrogen, the oil phase is stirred and subjected to a polymerization reaction at a certain temperature, and a resultant is subjected to filtering, washing, Soxhlet extraction, and vacuum drying treatments to obtain the macroporous crosslinking copolymerization microballoon. The above synthetic method has the advantages of safety, easy separation of products, low production cost, easy control of temperature, stable product quality the like, and is suitable for large scale industrial production. Since having porous and hydrophobic characteristics, the hydrophobic macroporous microballoon disclosed in the invention has a substantial advantage in removing enriched hydrophobic organic pollutants in water, which is a prospective environment friendly adsorption material and can be effectively used for processing relative organic waste water. The hydrophobic macroporous microballoon also has potential application value in fields of catalyst and drug carrier, bioseparation and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Aporate amphion switching biology isolate medium as well as its preparing method and usage

InactiveCN101157059AIrreversible adsorption is smallUnique craftCation exchanger materialsOrganic anion exchangersMicrosphereIon exchange

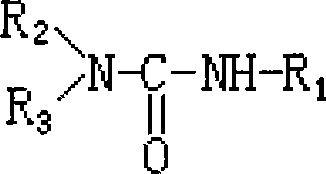

The invention relates to a non-porous amphoteric ion exchange biological separation medium. The structural formula is shown in figure, and the non-porous amphoteric ion exchange biological separation medium has a preparation method that 40 to 60 ML 1.0 mol / L of diluted HCl is added into 4.0 to 6.0 g non-porous monodisperse P (GMA / EDMA) resin, which is reacted for 2 to 3 hours in the constant temperature at 30 to 40 DEG C after being supersonicly dispersed for 10 to 15 minutes, filtered, and repeatedly cleaned with distilled water to be neutral; the water solution of 30 to 50 ML dimethylamine is further added into the resultant, which is reacted for 20 to 24 hours in the constant temperature at 60 to 70 DEG C; the resultant is repeatedly cleaned with a great amount of water and acetone, and performed the vacuum drying, thereby obtaining ammoniation microspheres; the microspheres after ammoniation are laid in acetonitrile of 120 to 150 ML, 3 to 5 g 1,3-Propanesultone is added, the return flow agitation is performed for 20 to 24 hours at 80 to 90 DEG C after the ultrasonic dispersion, and the resultant is cleaned with a great amount of acetone and ethyl alcohol, and performed the vacuum drying, thereby obtaining the non-porous amphoteric ion exchange biological separation medium. The invention takes 3.0 micron non-porous monodisperse porous poly-glycidylmethacrylate-co-ethylene dimethacrylate resin as a matrix, the adoption of a new chemical modified method prepares novel protein which can simultaneously separate the acidity and the alkality, the protein has the advantages of easy regeneration, strong acid and strong base resistance, high mechanical strength, rapid separation velocity, and high protein quality and activity recovery ratio, and the protein can be widely used for rapid separation and purification of gene engineering products and the protein.

Owner:NINGXIA UNIVERSITY

Three-element copolymerized hydrogel, preparation method thereof and application thereof in water treatment

InactiveCN102199246AImprove pore structureGuaranteed pureOther chemical processesAlkali metal oxides/hydroxidesEthylene dimethacrylateChelation heavy metals

The invention relates to a three-element copolymerized hydrogel and a preparation method thereof. The preparation method is simple, and easy to implement; and the obtained three-element copolymerized hydrogel can effectively adsorb Cr3+, Cd2+, Cu2+ and Pb2+ ions. The preparation method for the three-element copolymerized hydrogel comprises the following step of: performing radiation polymerization on hydroxyethyl acrylate, n-ethylene dimethacrylate and 2-acrylamide-2-methylpropanesulfonic acid, wherein the molar ratio of the hydroxyethyl acrylate to the n-ethylene dimethacrylate to the 2-acrylamide-2-methylpropanesulfonic acid is (1-2):(0.1-0.6):(0.1-0.7); the n-ethylene dimethacrylate monomer is one of 2G, 4G, 9G and 14G; the radiation dosage of radiation polymerization is 1*103-1*106Gy;and the polymerization temperature is between -63 and -95DEG C. The invention has the advantages that: the three-element copolymerized hydrogel can effectively adsorb and chelate heavy metal ions; and the preparation method is simple, and easy to implement.

Owner:NANJING UNIV

Preparation method of magnetic material for removing dibenzothiophene from oil

ActiveCN102675537ALow priceEasy to separateOther chemical processesOrganic/organic-metallic materials magnetismFunctional monomerFiltration

The invention discloses a preparation method of a magnetic material for removing dibenzothiophene from oil. The method comprises the following steps of: preparing magnetic nanometer ferroferric oxide; preparing into a pre-assembled solution; dissolving polyvinyl pyrrolidone into a methylbenzene solution; adding azodiisobutyronitrile and a prepolymer solution to obtain a polymer; separating the obtained polymer in an external magnetic field; and putting into a mixed solution of methanol and glacial acetic acid to obtain a magnetic material. Compared with the conventional molecular engram material, a ferroferric oxide magnetic molecular engram polymer magnetic material which is synthesized by taking tetravinyl pyridine as a functional monomer, taking dibenzothiophene as a template molecule, taking ethylene glycol ethylene dimethacrylate as a crosslinking agent and taking oleic acid-coated ferroferric oxide as a load substrate with a surface molecular engram technology has the advantages of uniform particle, high mechanical strength and no need of complex steps during suction filtration and centrifugal separation, has certain adsorption volume and adsorption selectivity to dibenzothiophene in oil, and is a novel material which is low in price and is convenient and rapid for separating.

Owner:JIANGSU UNIV

Modified-acrylic-acid coated synergic sustained-release composite fertilizer

The invention relates to the field of composite fertilizers, and concretely relates to a modified-acrylic-acid coated synergic sustained-release composite fertilizer. The fertilizer is prepared from the following raw materials in parts by weight: 10-15 parts of 1250-2000 mesh diatomite, 5-6 parts of castor shell, 10-12 parts of rapeseed meal, 4-5 parts of traditional Chinese medicine residue, 5-6 parts of bamboo sawdust, 2-4 parts of zinc gluconate, 3-4 parts of ferrous sulfate, 2-3 parts of sodium thiosulfate, 6-8 parts of ethylene dimethacrylate, 10-12 parts of corn bran, 8-10 parts of potassium chloride, 12-15 parts of urea, 20-25 parts of ammonium dihydrogen phosphate, 8-10 parts of vinasse, 1-2 parts of sodium dodecyl sulfate, 12-15 parts of acrylic acid, 12-15 parts of decomposed manure, 2-3 parts of soybean powder, 2-4 parts of zinc acetate, 1-2 parts of sodium acetate and 4-5 parts of an auxiliary agent. The composite fertilizer is abundant in raw material kinds, abundant and multiple in nutrients and rich in organic materials, is capable of protecting soil and enhancing soil fertility; and dual cladding on nutrients is formed by utilizing a sustained-released coating agent prepared from diatomite and modified acrylic acid in the technology, so that the fertilizer efficiency is relatively durable, the fertilizer utilization rate is greatly improved, and increasing on both production and income of crops is guaranteed.

Owner:辽宁翠龙肥业集团有限公司

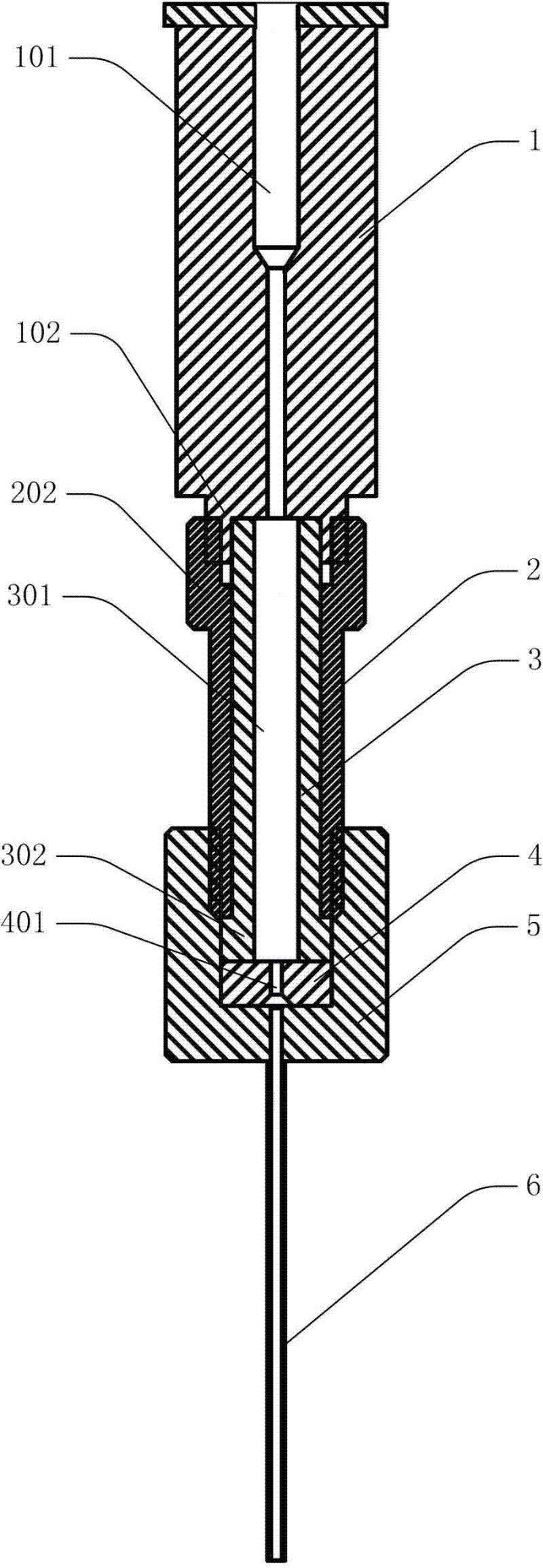

Extraction material and preparation method thereof, and device and extraction method used for solid-phase micro-extraction

ActiveCN102688749ALow costSimple structureIon-exchange process apparatusOther chemical processesSolid-phase microextractionDesorption

The invention provides an extraction material in the following component proportion: that methacrylic acid: ethylene dimethacrylate is 1:1 to 1:8 (in molar ratio); that (methacrylic acid +ethylene dimethacrylate): methanol is 1:5 to 1:40 (in molar ratio); and that the content of azodiisobutyronitrile is 1% to 2% of the total amount of the material (by mass). A preparation method of the extraction material comprises that the above materials are mixed according to the component proportion to form a pre-polymerization solution; that the pre-polymerization solution is processed by ultrasonic and reacts; and that that methanol is introduced into the reacted pre-polymerization solution to remove not reacted reagent. A solid-phase micro-extraction device comprises a draw-off device, an injection device and an extraction tube, wherein two ends of the extraction tube are connected to the draw-off device and the injection device respectively, and the extraction tube is axially equipped with a through hole which is filled with the extraction material. A solid-phase micro-extraction method comprises the steps of preparation, extraction, purification, desorption, and cleaning. According to the invention, the cost is low, and the working efficiency is high.

Owner:上海新拓分析仪器科技有限公司

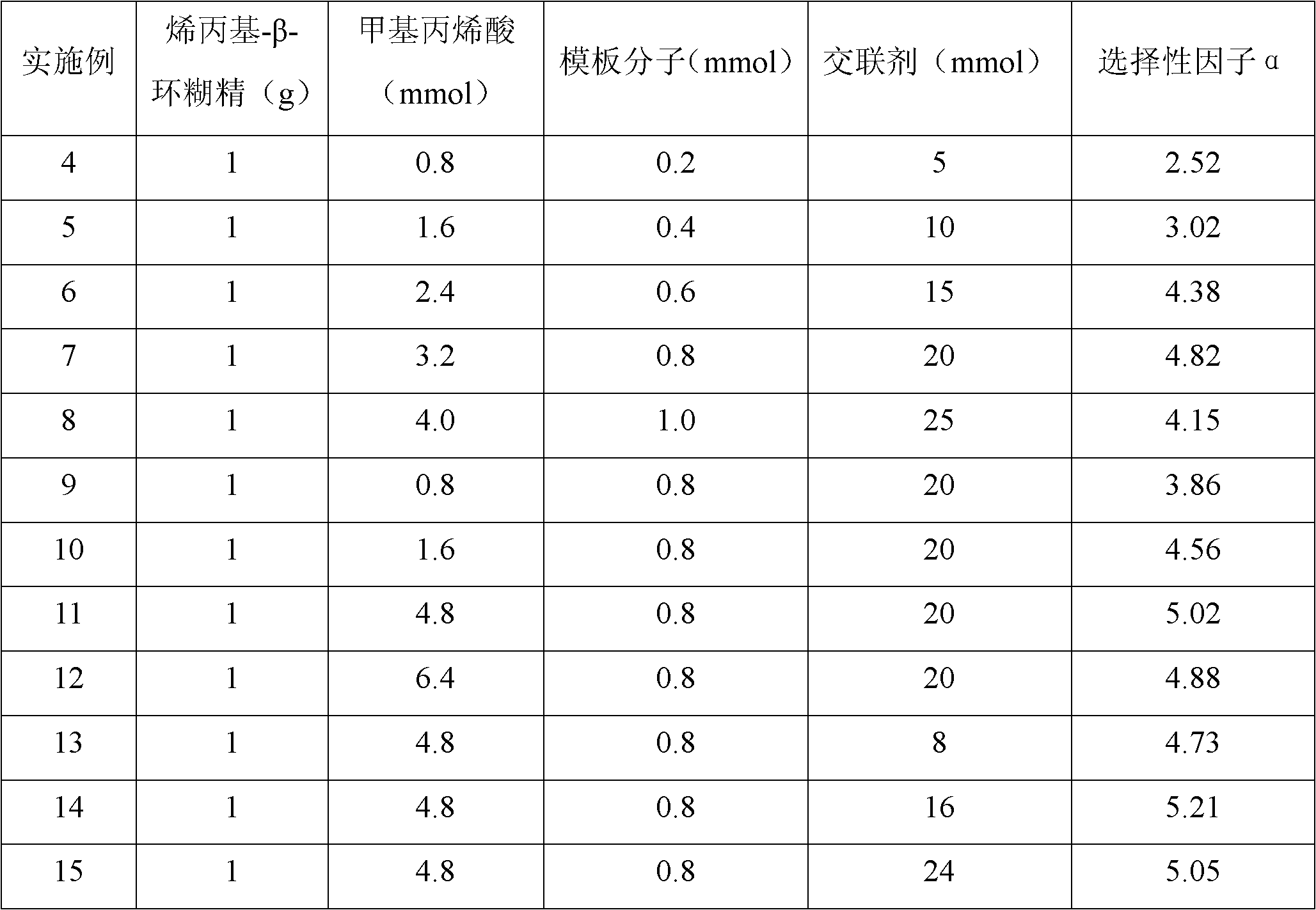

Strychnine detection material prepared by using bifunctional monomers

The invention provides a strychnine molecular imprinting polymer and its preparation method, the method comprises the following steps: dissolving the functional monomers and the template molecule strychnine in dimethyl sulfoxide, mixing for 6-24 hours at room temperature, then adding a cross-linking agent ethylene dimethacrylate and an initiator, performing ultrasonic degassing, introducing nitrogen for deoxygenation, sealing and carrying out thermal-initiated polymerization, cleaning and removing the template molecule, wherein the functional monomers contain allyl-beta-cyclodextrin and methacrylic acid. According to the invention, the molecular recognition capability of the beta-cyclodextrin and the molecular recognition capability of the molecular imprinting technology are used for preparing the strychnine molecular imprinting polymer, the proportion of various raw materials are optimized to obtain good recognition effect. The modification of the beta-cyclodextrin has large influence on its molecular recognition effect, therefore allyl which possesses small structure modification to the beta-cyclodextrin can be selected and introduced to a polymerizable unit, and dual recognition capability of the beta-cyclodextrin and the molecular imprinting technology can be fully used to increase the recognition capability. The bifunctional monomers and a plurality of recognition modes are used for raising the recognition capability further.

Owner:成都市龙泉驿区十陵禽业合作社

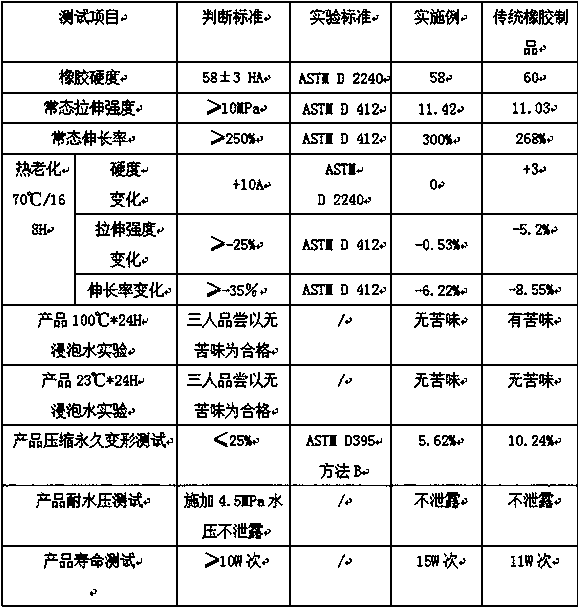

Ethylene-propylene-diene monomer rubber sealing membrane for water dispenser and production process thereof

The invention provides an ethylene-propylene-diene monomer rubber sealing membrane for a water dispenser and a production process thereof. The ethylene-propylene-diene monomer rubber sealing membranefor the water dispenser comprises the following raw materials in parts by weight: 100 parts of an ethylene-propylene-diene monomer, 1-5 parts of zinc oxide, 0.5-2 parts of stearic acid, 0.5-4 parts ofa dispersant, 30-70 parts of carbon black, 6-20 parts of a filler, 10-40 parts of a plasticizer, 1-5 parts of a vulcanizing agent, and 1-5 parts of a vulcanizing auxiliary agent; the vulcanizing agent is 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, and the vulcanizing auxiliary agent is ethylene dimethacrylate. The vulcanizing agent is 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane; the vulcanizingauxiliary agent is ethylene dimethacrylate, and no sulfhydryl group is generated during the reaction; anti-aging agents are not needed, addition of sulfhydryl groups is eliminated from the raw materials; therefore, the product does not produce bitterness, the boiling process is not needed, production efficiency is improved, manpower and material resources are reduced, and production costs is reduced; traditional anti-aging agents are not needed, product performance is superior to performance of traditional rubber products.

Owner:广东贝洛新材料科技有限公司

Novel macroporous weak acid cation exchange resin and preparation method thereof

InactiveCN109694440AReduce dosageImprove hydrophilicityCation exchanger materialsDivinylbenzeneAcrylonitrile

The invention relates to a novel macroporous weak acid cation exchange resin and a preparation method thereof, and belongs to the technical field of ion exchange resins, wherein the ion exchange resincomprises an oil phase and an aqueous phase, wherein the oil phase comprises divinylbenzene, ethylene dimethacrylate, itaconic acid, methyl acrylate, acrylonitrile, toluene, 200# gasoline and azobisisobutyronitrile, and the aqueous phase comprises deionized water, a 10% polyvinyl alcohol solution, gelatin and sodium chloride. According to the present invention, no pollution is generated to waterduring the preparation, the cost is low, and the comprehensive performance of the product is strong.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Preparation method and application method of atrazine surface molecularly imprinted magnetic mesoporous material

InactiveCN108246266ALarge adsorption capacityShort equilibration timeOther chemical processesWater contaminantsCross-linkFunctional monomer

The invention relates to a preparation method and an application method of an atrazine surface molecularly imprinted magnetic mesoporous material, and belongs to the technical field of composite material. The preparation method comprises following steps: sol-gel method is adopted to coat the surface of ferriferrous oxide with a layer of mesoporous silica, modification with vinyl tri-methoxysilaneis carried out, mixing with an acetonitrile solution of functional monomer itaconic acid is carried out, initiator azodiisobutyronitrile is added for a certain time of reaction, atrazine is added, nitrogen is introduced into a reaction system to remove oxygen for prepolymerization, azodiisobutyronitrile and cross-linking agent ethylene dimethacrylate are added for polymerization; an applied magnetic field is adopted for magnetic separation of obtained products; a mixed solution of acetic acid and methanol is adopted for elution of template molecules, and then magnetic separation and vacuum drying are carried out so as to obtain the atrazine surface molecularly imprinted magnetic mesoporous material. In the application method, the atrazine surface molecularly imprinted magnetic mesoporous material is added into sample solutions such as environment water sample or food containing atrazine, so that high efficiency adsorption separation on atrazine can be realized, treatment speed is high,anti-interference capability is excellent, the atrazine surface molecularly imprinted magnetic mesoporous material can be recycled for a plurality of times, and the application value of the atrazinesurface molecularly imprinted magnetic mesoporous material in selective adsorption removing of atrazine and detection pretreatment of trace atrazine is high.

Owner:GUANGDONG UNIV OF TECH

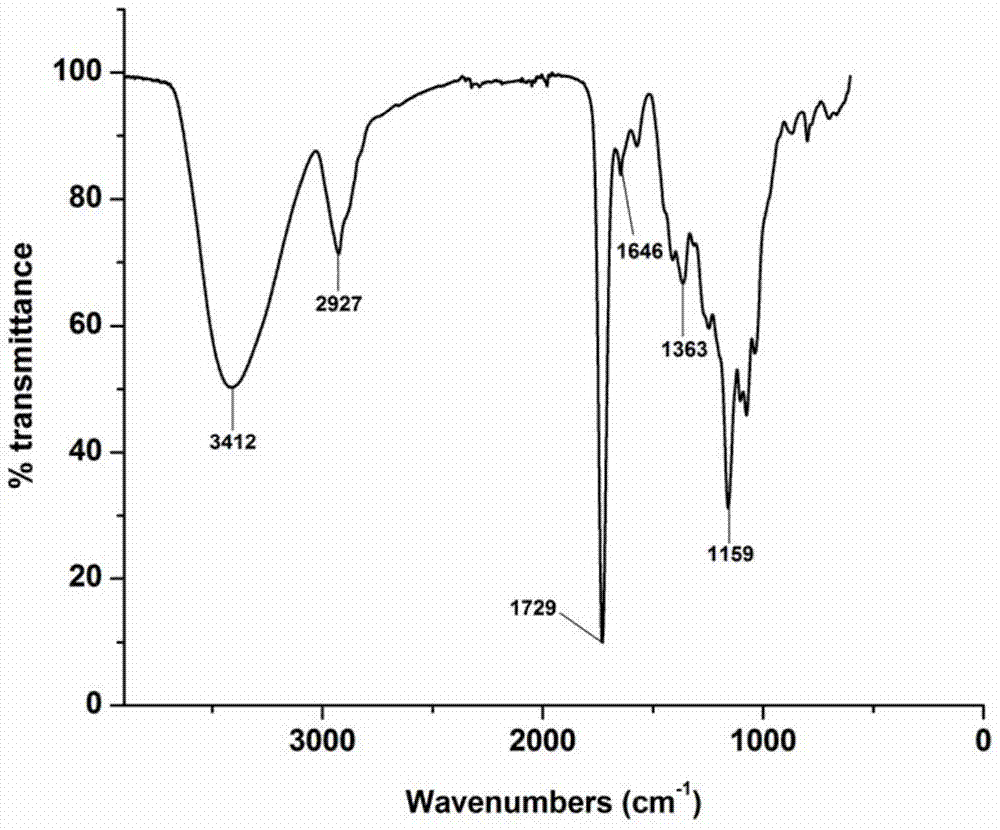

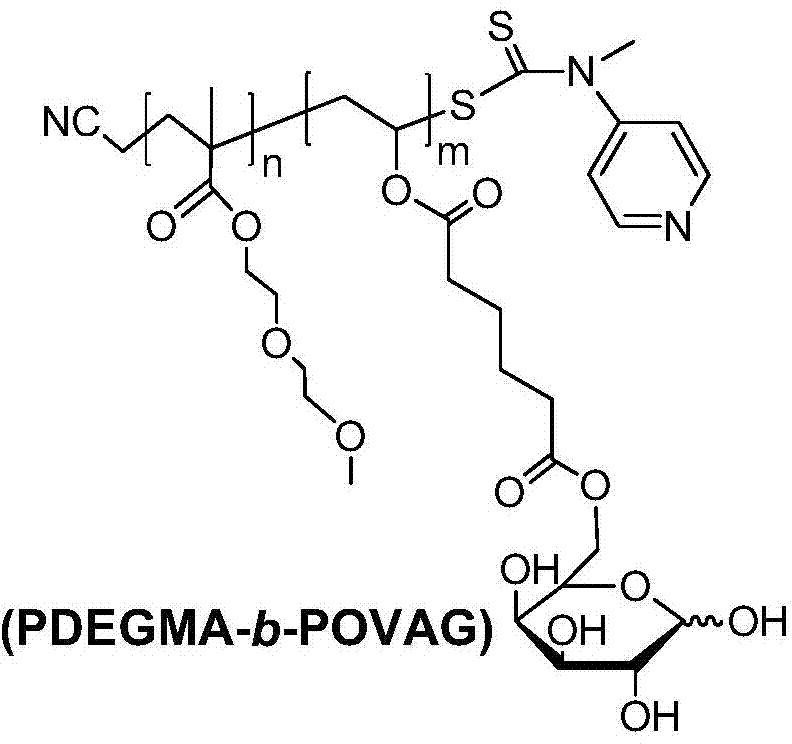

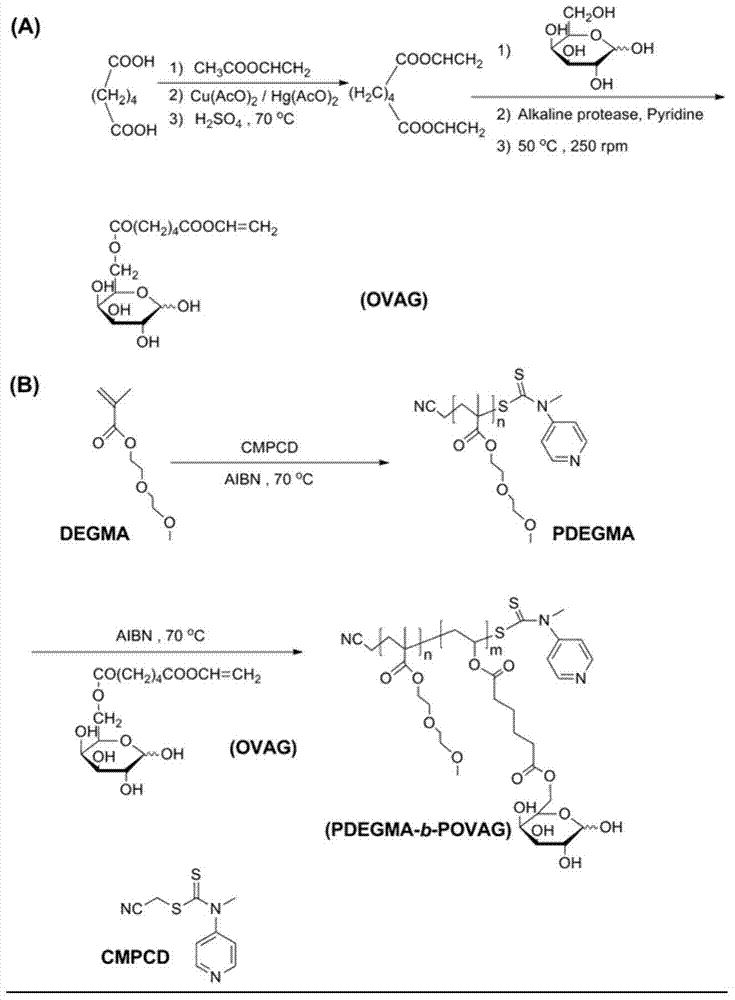

Method for synthesizing galactose block copolymer employing RAFT (reversible addition fragmentation chain transfer) method

The invention relates to a method for synthesizing a galactose block copolymer employing an RAFT (reversible addition fragmentation chain transfer) method. The method comprises the following steps: dissolving divinyl adipate and galactose into a solvent, adding alkaline protease, and carrying out reaction under stirring at 40-50 DEG C for 4-5 days, so as to obtain vinyl adipic acid galactose OVAG; dissolving macromolecular PDEGMA which is formed by polymerization of OVAG and diglycol ethylene dimethacrylate DEGMA into a solvent as a chain transfer agent; and adding an initiator AIBN, reacting in an oil bath at 70 DEG C under a nitrogen protection condition for 48 hours, terminating reaction, and purifying, so as to obtain the galactose block copolymer. A reactive monomer is synthesized by an enzyme-promoting method; the method is high in selectivity and high in yield; the obtained sugar-based monomer is high in purity; the galactose block copolymer is synthesized by the RAFT method; the synthesis reaction is stable; implosion is not caused; the molecular weight dispersing width of the product obtained by reaction is low; and the obtained copolymer has the advantages of biocompatibility and relatively low toxicity, and can be widely applied in the field of biological medicines.

Owner:DONGHUA UNIV

Preparation method of retinervus luffae fructus surface procyanidin molecular imprinting adsorption material

InactiveCN107126938ASpecific recognition abilityHigh selectivityOther chemical processesSolid sorbent liquid separationOxygenChemical stability

The invention discloses a preparation method of a retinervus luffae fructus surface procyanidin molecular imprinting adsorption material. The preparation method comprises: carrying out surface modification on retinervus luffae fructus by using gamma-glycidoxypropyltrimethoxysilane to obtain surface modified retinervus luffae fructus; respectively adding 52-62% of ethanol, 10-15% of ethylene dimethacrylate, 6-10% of N-vinylpyrrolidone, 4.0-8.0% of procyanidin, 10-15% of the surface modified retinervus luffae fructus, and 1.0-3.0% of azobisisobutyronitrile to a reactor; and carrying out stirring dissolving, carrying out a stirring reaction for h in the absence of oxygen, and removing the template molecule from the obtained product by using a methanol and acetic acid mixed solution so as to obtain the retinervus luffae fructus surface procyanidin molecular imprinting adsorption material. According to the present invention, the retinervus luffae fructus surface procyanidin molecular imprinting adsorption material can specifically recognize procyanidin, and further has advantages of high selectivity, good chemical stability, fast adsorption, easy elution, biodegradability, simple process, regenerative ability, environmental protection, and the like.

Owner:UNIV OF JINAN

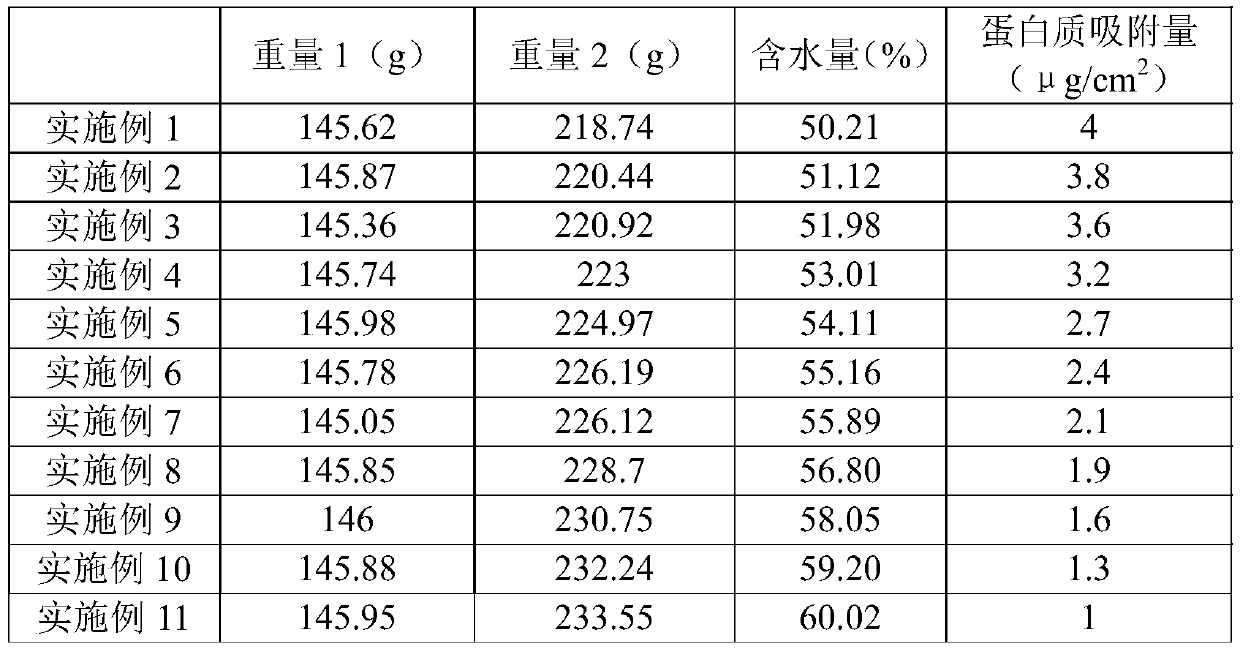

Separation medium for purifying proteins, and preparation method thereof

InactiveCN104497205ASolve the problem of low purity and poor product qualityImprove performancePeptide preparation methodsPolymer scienceMeth-

The invention relates to a separation medium for purifying proteins, and a preparation method thereof, and belongs to the technical field of polymer materials. The separation medium for purifying proteins includes an oil phase and a water phase, wherein the oil phase comprises glycidyl methacrylate, ethylene dimethacrylate, triallyl isocyanurate, divinyl benzene, hydroxypropyl acrylate, toluene, gasoline, isoamyl alcohol and azoisobutyronitrile; and the water phase comprises deionized water, polyvinyl alcohol, gelatin, sodium chloride and methylene blue. The separation medium is prepared by selecting suitable monomers through a polymerization reaction, has the respective advantages of natural saccharide and synthetic polymer separation media, also has the advantages of macro-porous structure, high adsorption rate, large specific surface area and large adsorption capacity, and is separation medium having excellent performances and used for separating and purifying the proteins. The adsorption capacity of the medium provided by the invention to bovine serum albumin (BSA) can reach 171.20mg / g dry resin.

Owner:CHENGDU JINHUI TECH

Weather-proof cable material for wind turbine generator

InactiveCN105713397AReduce aggregationReduce entanglementRubber insulatorsLow-density polyethylenePyrophosphate

The invention discloses a weather-proof cable material for a wind turbine generator. The weather-proof cable material comprises raw materials in parts by weight as follows: 15-35 parts of nitrile silicone rubber, 20-30 parts of an ethylene-propylene alpha-olefin copolymer, 1-4 parts of a maleic anhydride grafted ethylene-vinyl acetate copolymer, 10-30 parts of nylon modified low-density polyethylene, 2-4 parts of N,N-diisopropylaniline, 10-20 parts of nano-silica, 10-20 parts of kaolin, 20-40 parts of modified rice protein, 40-60 parts of nano calcium carbonate, 5-15 parts of ammonium polyphosphate, 1-2 parts of 4,4'-diaminodicyclohexyl methane, 1-2 parts of bis(tert-butyl dicumyl peroxide), 0.2-0.8 parts of gamma-glycidoxypropyl trimethoxysilane, 1-2 parts of dibenzoyl peroxide, 0.5-1.2 parts of ethylene dimethacrylate, 1-2 parts of 2,6-di-tert-butyl-4-methylphenol, 1-5 parts of melamine pyrophosphate, 2-5 parts of melamine cyanurate and 2-4 parts of a lubricant. The weather-proof cable material has excellent thermal stability and mechanical properties as well as excellent corrosion resistance and ageing resistance.

Owner:ANHUI SPECIAL CABLE GRP

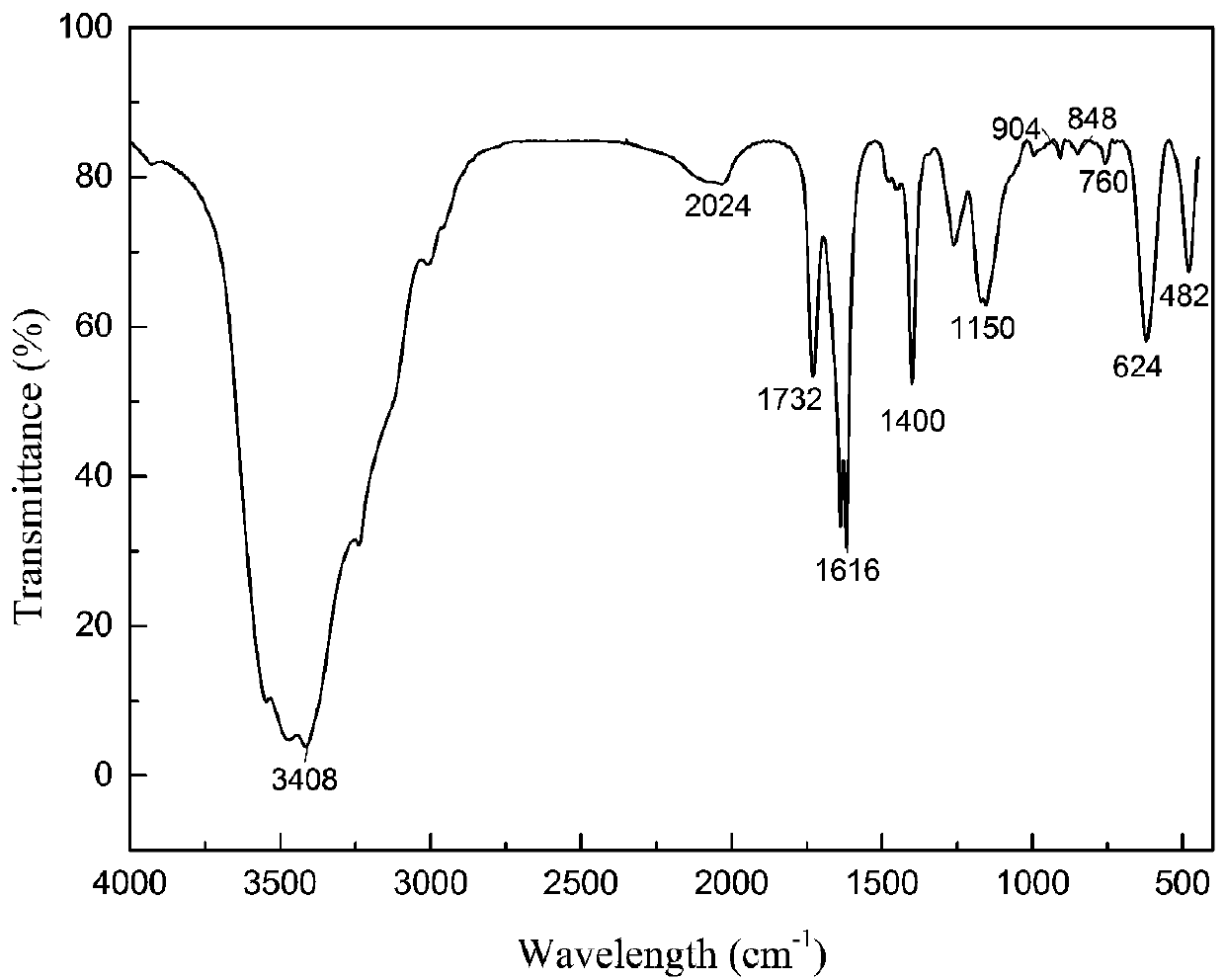

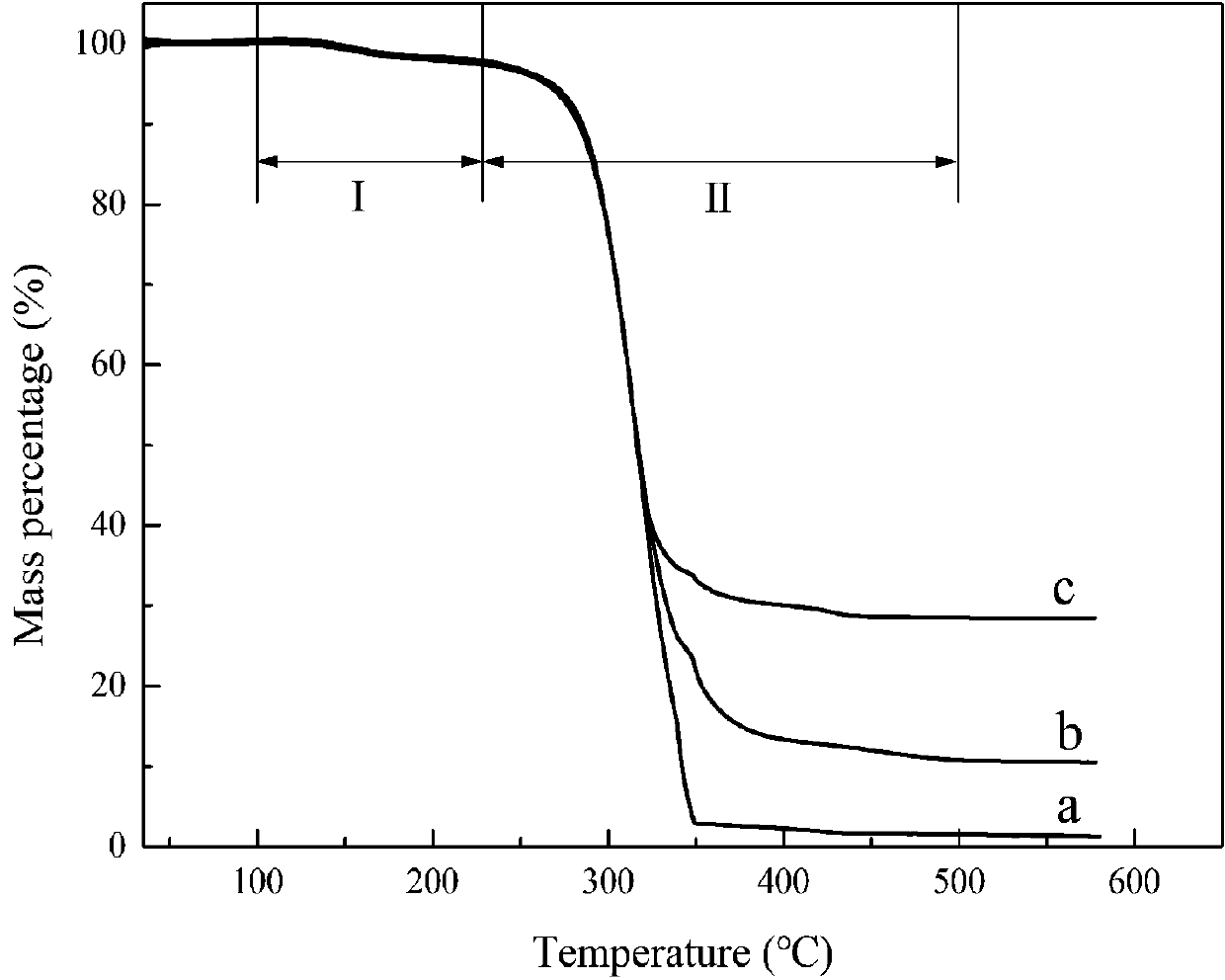

Hydrogel material with water content of 50%-60% and preparation method thereof

InactiveCN110256626AImprove hydrophilicityExcellent anti-protein adsorption performanceOptical parts2-methacryloyloxyethyl phosphorylcholineOligomer

The invention relates to a hydrogel material with water content of 50%-60% and a preparation method thereof. The hydrogel is prepared by the following method: the hydrogel is prepared by the following raw materials, by mass percent: 79%-94$ of a hydrophilic comonomer hydroxyethyl methylacrylate, 5%-20% of a hydrophilic substance 2-methacryloyloxyethyl phosphorylcholine, 0.2%-5% of a crosslinking agent ethylene dimethacrylate, and 0.1%-2% of an initiator azodiisobutyronitrile; the raw materials are mixed and uniformly stirred; the raw materials are injected into a mould, and the reaction mixture is solidified by a method of heat initiation; and demoulding is carried out, and the unreacted monomers or oligomers are removed to obtain the hydrogel material with the water content of 50%-60%. Compared with the prior art, the hydrogel material with the water content of 50%-60% and the preparation method thereof have the advantages of simple preparation method and easy operation.

Owner:甘肃天后光学科技有限公司

Activated clay-modified fluorocarbon heat-insulating radiative coating and preparation method thereof

InactiveCN106497252AImprove wear resistanceGood adhesionAntifouling/underwater paintsPaints with biocidesVinyl etherSodium bicarbonate

The invention provides an activated clay-modified fluorocarbon heat-insulating radiative coating. The activated clay-modified fluorocarbon heat-insulating radiative coating is characterized by being prepared from the following raw materials: trifluorochloroethene, infrared absorption nanometer powder, perfluoromethylvinyl ether, perfluorobutylethyl acrylate, ethylene dimethacrylate, ammonium persulfate, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, glycerol monolaurate, activated clay, hectorite, nanometer tungsten trioxide, propylene glycol, butyl acetate, epoxidized castor oil, polydimethylsiloxane, 2-methyl methacrylate, hydroxyethyl cellulose, n-dodecanol ester, phenethyl phenol polyoxyethylene ether, a proper amount of sodium bicarbonate and a proper amount of deionized water. The activated clay-modified fluorocarbon heat-insulating radiative coating has good heat insulation effect, excellent mechanical performance, excellent adhesion, and superior weatherability, water resistance, stain resistance, scrubbing resistance and the like; and the coating is safe, environment-friendly and wide in an application scope.

Owner:ANHUI JISITE INTELLIGENT EQUIP CO LTD

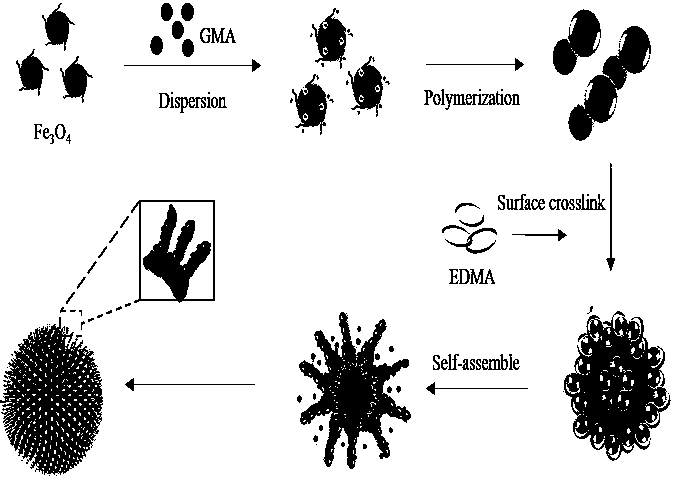

Starlike magnetic response organic adsorption material and preparation method thereof

InactiveCN107552022ASolve the adsorption problemFix compatibility issuesOther chemical processesAlkali metal oxides/hydroxidesSorbentMagnetic response

The invention relates to a starlike-structured adsorption material and a preparation method thereof and belongs to the technical field of a preparation technology of a high polymer material. The starlike magnetic response material used for efficiently, rapidly and conveniently separating and purifying protein comprises raw materials as follows: a continuous phase and a dispersion phase, wherein the continuous phase comprises ethanol, toluene and polyvinylpyrrolidone, and the dispersion phase comprises GMA (glycidyl methacrylate), EDMA (ethylene dimethacrylate ), azodiisobutyronitrile, dodecanol, cyclohexanol and Fe3O4. Polymeric microspheres are controlled to perform surface crosslinking self-assembly with a dispersion polymerization method, so that a starlike magnetic response polymer adsorbent is formed. The prepared starlike magnetic response organic adsorbent not only has high specific surface area, high adsorption sites and high adsorbing capacity of a microsphere adsorbent, but also has the characteristics of large macro particle size, high magnetic response strength and the like, two characteristics including efficient adsorption and convenient separation of a biological macromolecular adsorbent are integrated, and a separation material with good performance is provided for the field of the bioseparation materials. The adsorption capacity of the material for BSA (bovineserum albumin) can reach 108 mg per g of a dry-based material.

Owner:SICHUAN UNIV

Waterproof antibacterial marine coating

InactiveCN104945969AImprove adhesionReduce adhesionAntifouling/underwater paintsPaints with biocidesFuranGluconic acid

The invention discloses a waterproof antibacterial marine coating. Raw materials of the marine coating comprise the following ingredients, by weight, 45-60 parts of a fluorine-silicon modified acrylic emulsion, 30-45 parts of a vinyl acetate emulsion, 4-10 parts of polypropylene fiber, 5-15 parts of silicon nitride, 1-5 parts of graphite oxide, 20-35 parts of liquid petroleum resin, 1-3 parts of ethylene dimethacrylate, 2-5 parts of 3-methacryloxy propyl trimethoxy silane, 0.5-2 parts of tri-n-butyl phosphate, 3-8 parts of oxidized starch, 5-10 parts of polyvinyl alcohol, 1-3 parts of glycol, 1-4 parts of dipropylene glycol mono butyl ether, 0.3-1 part of hydroxy propyl distarch phosphate, 0.3-1.5 parts of sodium gluconate, 0.3-1.5 parts of 2-furan-dimethyl silanol, 5-10 parts of an auxiliary agent and 20-35 parts of water. The waterproof antibacterial marine coating brought forward in the invention has advantages of high hardness, excellent waterproofness and antibacterial property, good comprehensive performance and long service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Polishing fluid for stainless steel materials and preparation method thereof

A disclosed polishing fluid for stainless steel materials is characterized by being prepared from the following raw materials in parts by weight: 7-9 parts of aluminium oxide, 3-5 parts of magnesium oxide, 2-3 parts of manganese oxide, 1-2 parts of zinc sulfate, 2.5-3.5 parts of polyvinylpyrrolidone, 4-6 parts of ethylene dimethacrylate, 3.5-5 parts of disodium hydrogen phosphate, 1-2 parts of lithium bis(trifluoromethanesulphonyl)imide, 1-2 parts of methionine, 4-6 parts of tween 80, 5-7 parts of an auxiliary agent, and 300 parts of deionized water. The prepared mixed polishing fluid is safe, non-toxic, free of unpleasant smells, and reasonable in formula. Through the cooperation of the abrasive and the surfactant, preferential adsorption is realized, and a long-term easily-cleaned physical adsorption surface is formed. The polishing fluid belongs to an aqueous polishing fluid, is capable of substantially reducing temperature caused by friction during polishing, avoiding burn phenomenon on a material surface and giving play to good cooling effect. The polishing fluid is added and used when a stainless-steel material machine needs polishing.

Owner:BENGBU TIANGUANG SENSOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com