Preparation method of magnetic material for removing dibenzothiophene from oil

A technology of dibenzothiophene and magnetic material, which is applied in the field of environmental pollution control chemistry, can solve the problems of reducing gasoline octane number environmental pollution, high price of adsorption materials, low selectivity, etc., and achieves improved imprinting function, convenient and rapid separation, The effect of high adsorption selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

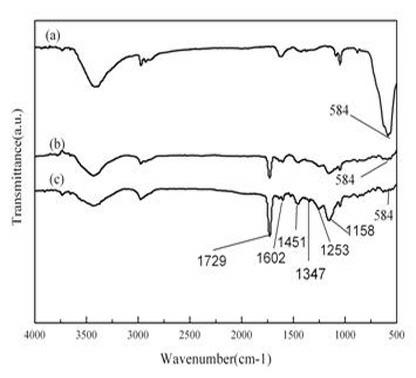

[0016] The preparation method of the present invention is divided into four steps, followed by ferric oxide (Fe 3 o 4 ) the synthesis of magnetic nanoparticles, the coating of oleic acid on the surface of ferric oxide nanoparticles, the coating of molecular imprinted layer on the surface of oleic acid, and the elution of template dibenzothiophene (DBT) and the generation of recognition sites, as follows:

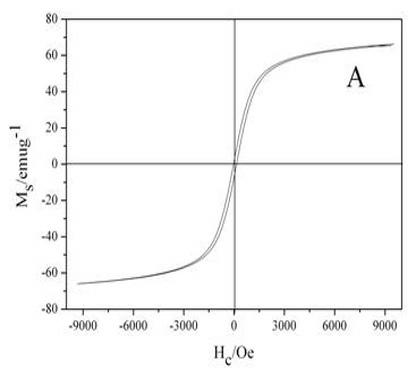

[0017] Step 1: Prepare superparamagnetic Fe3O4 nanoparticles by co-precipitation method. The Fe3O4 nanoparticles to be prepared must be smaller than 25nm to ensure their superparamagnetism. Therefore, weigh 0.5-2.5g of ferrous chloride tetrahydrate and 3-8g of ferric chloride hexahydrate, dissolve them in 40-80ml of water, stir for 10-60min under the protection of nitrogen, and at the same time add 5-20ml of Ammonia, continue to stir under the protection of nitrogen for 10-60min. The above solution is washed to neutrality, and can be washed to neutrality with distilled wat...

Embodiment 1

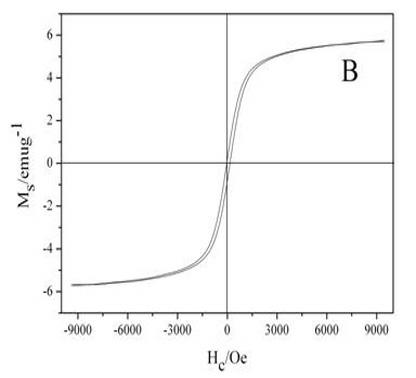

[0025] Using 4-vinylpyridine (4-VP) as the functional monomer, dibenzothiophene (DBT) as the template molecule, and ethylene glycol dimethacrylate (EGDMA) as the cross-linking agent, the surface modified 4-VP Ferric oxide was used as the loading matrix, and molecularly imprinted polymers on the surface of magnetic materials were synthesized. Accurately weigh 0.1843g of dibenzothiophene (DBT) and 0.425ml of 4-vinylpyridine (4-VP) and dissolve them in 10ml of toluene, and stir for 1 hour to prepare a pre-assembly solution. 16mmol of cross-linking agent ethylene glycol dimethacrylate and pre-assembly solution were added to ferric oxide coated with oleic acid prepared in advance, and the mixed solution was ultrasonicated for 15 min at room temperature to prepare a pre-polymer solution. Dissolve 0.2g of polyvinylpyrrolidone (PVP) in 10ml of toluene, stir at 300rpm, pass nitrogen to remove oxygen, and heat to 60°C. Add 0.05g of azobisisobutyronitrile (AIBN) and prepolymer, and reac...

Embodiment 2

[0027]Using 4-vinylpyridine (4-VP) as the functional monomer, dibenzothiophene (DBT) as the template molecule, and ethylene glycol dimethacrylate (EGDMA) as the cross-linking agent, the surface modified 4-VP Ferric oxide was used as the loading matrix, and molecularly imprinted polymers on the surface of magnetic materials were synthesized, and 0.3686g of dibenzothiophene (DBT) and 0.85ml of 4-vinylpyridine (4-VP) were accurately weighed and dissolved in 100ml of toluene . After stirring for 2 hours, a pre-assembly solution was made. 40 mmol of crosslinking agent ethylene glycol dimethacrylate (EGDMA) and pre-assembly solution were added to the pre-prepared ferric iron tetroxide coated with oleic acid, and the mixed solution was ultrasonicated for 30 min to prepare a pre-polymer solution. Dissolve 0.8g of polyvinylpyrrolidone (PVP) in 100ml of toluene, stir at 300rpm, pass nitrogen to remove oxygen, and heat to 60°C. Add 0.2g of azobisisobutyronitrile (AIBN) and prepolymer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com