Ethylene-propylene-diene monomer rubber sealing membrane for water dispenser and production process thereof

A technology of EPDM rubber and sealing film, applied in the field of sealing film, can solve the problems of rising product cost, waste of manpower, unpleasant taste, smell, etc., and achieve excellent product performance, save manpower and material resources, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

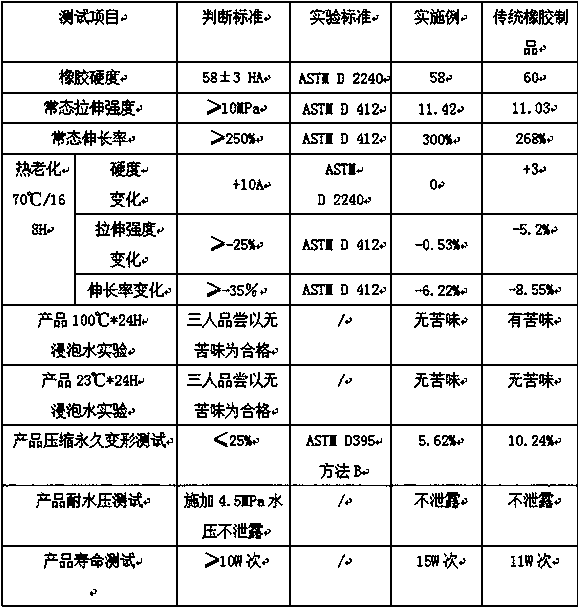

Examples

Embodiment Construction

[0018] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below.

[0019] The embodiment provided by the present invention is an EPDM rubber sealing diaphragm for drinking fountains, comprising the following raw materials by weight: 100 parts EPDM rubber, 3 parts zinc oxide, 1.25 parts stearic acid, 2.25 parts Dispersant, 50 parts carbon black, 13 parts filler, 25 parts plasticizer, 3 parts vulcanizing agent, 3 parts vulcanization aid.

[0020] The vulcanizing agent is 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane provided by Jinchangsheng, and the vulcanizing assistant is ethylene glycol methacrylate.

[0021] Among them, the EPDM rubber is KEP330 provided by Kumho, South Korea, with an ENB content of 7.9%; the carbon black is carbon black N550 provided by Cabot, the filler is precipitation white carbon black N355 provided by Pinyou, and the dispersant is Rheinland The Laings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com