Preparation method and application of ZnS quantum dot silica-based surface molecular imprinting sensor

A technology of surface molecular imprinting and quantum dots, which is applied in the direction of material excitation analysis, fluorescence/phosphorescence, etc., can solve the problems of long reaction time, complicated operation, poor selectivity, etc., achieve the improvement of sensitivity and selectivity, increase the reaction rate, and benefit The effect of desorption and recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

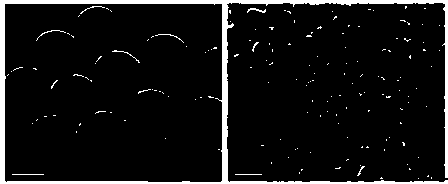

[0036] (1) In a 500 mL flask, add 100 mL of ethanol, 40 mL of deionized water and 15 mL of ammonia water. After vigorous magnetic stirring, add 10 mL of tetraethyl orthosilicate (TEOS), and stir for 2 h, the reaction produces SiO 2 , washed and precipitated, centrifuged, vacuum dried, and set aside. Take 1 g of SiO prepared above 2 Put it into a 100ml flask, add 45 mL of toluene, ultrasonically disperse, then add 1 mL of 3-(methacryloyloxy)propyltrimethoxysilane (KH570) dropwise under constant stirring, and heat up to 85 o C reflux for 20 hours. Centrifuge to get KH570 modified SiO 2 , washed with ethanol and dried for later use.

[0037] (2) In a 100 mL three-neck flask, add 1.797 g ZnSO 4 ·7H 2 O, 0.059 g MnCl 2 4H 2 O, add distilled water until completely dissolved, the resulting mixed solution was stirred at room temperature for 15 min under nitrogen, then added 5 mL containing 1.501 g Na 2 S·9H 2 O in water and stirred for 18 hours. Centrifuge to obtain Mn-dope...

Embodiment 2

[0041] (1) In a 500 mL flask, add 120 mL of ethanol, 60 mL of deionized water and 25 mL of ammonia water. After vigorous magnetic stirring, add 10 mL of tetraethyl orthosilicate (TEOS), and stir at room temperature for 2 h. SiO produced by reaction 2 , washed and precipitated, centrifuged, vacuum dried, and set aside. Take 1 g of SiO prepared above 2 Add 55 mL of toluene to a 100 mL flask, ultrasonically disperse, then add 3 mL of 3-(methacryloyloxy)propyltrimethoxysilane (KH570) dropwise under constant stirring, and heat up to 95 o C reflux for 28 hours. Centrifuge to get KH570 modified SiO 2 , washed with ethanol and dried for later use.

[0042] (2) In a 100 mL three-neck flask, add 1.797 g ZnSO 4 ·7H 2 O, 0.118 g MnCl 2 4H 2 O, add distilled water until completely dissolved, the resulting mixed solution was stirred at room temperature for 30 min under nitrogen, then added 5 mL containing 1.501 g Na 2 S·9H 2 O in water and stirred for 24 hours. Centrifuge to obt...

Embodiment 3

[0046] (1) In a 500 mL flask, add 110 mL of ethanol, 50 mL of deionized water and 20 mL of ammonia water. After vigorous magnetic stirring, add 10 mL of tetraethyl orthosilicate (TEOS), and stir at room temperature for 2 h. SiO produced by reaction 2 , washed and precipitated, centrifuged, vacuum dried, and set aside. Take 1 g of SiO prepared above 2 Add 50 mL of toluene to a 100 mL flask, ultrasonically disperse, then add 2 mL of 3-(methacryloyloxy)propyltrimethoxysilane (KH570) dropwise under constant stirring, and heat up to 90 o C reflux for 24 hours. Centrifuge to get KH570 modified SiO 2 , washed with ethanol and dried for later use.

[0047] (2) In a 100 mL three-neck flask, add 1.797 g ZnSO 4 ·7H 2 O, 0.1 g MnCl 24H 2 O, add distilled water until completely dissolved, the resulting mixed solution was stirred at room temperature for 20 min under nitrogen, then added 5 mL containing 1.501 g Na 2 S·9H 2 O in water, stirred for 20 hours. Centrifuge to obtain Mn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com