Hydrogel material with water content of 50%-60% and preparation method thereof

A hydrogel, water content technology, applied in optics, instruments, optical components, etc., to achieve the effect of enhancing comfort, good hydrophilicity, and good resistance to protein adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

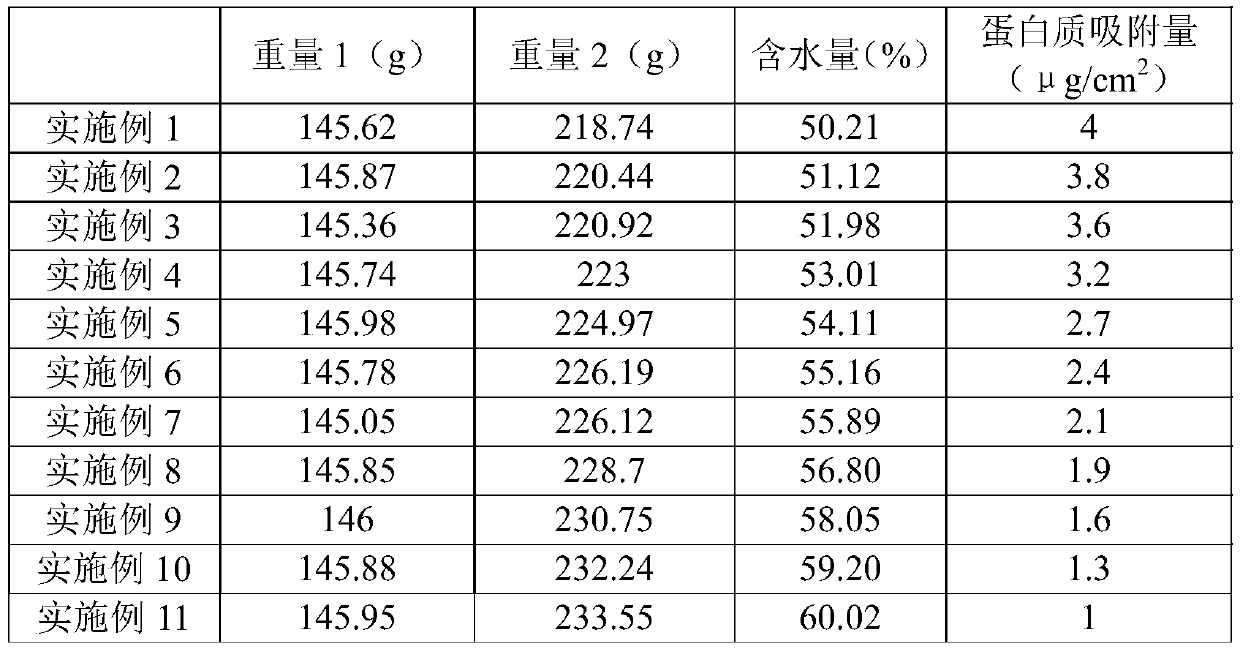

Examples

Embodiment 1

[0020] A hydrogel material with a water content of 50%-60%, which is prepared by the following method:

[0021] Step 1: Prepare raw materials according to the following weight: hydrophilic comonomer 2-hydroxyethyl methacrylate HEMA131.75g, hydrophilic substance 2-methacryloyloxyethylphosphorylcholine MPC12.37g, crosslinking agent two Ethylene glycol methacrylate EGDMA1.2g, initiator azobisisobutyronitrile AIBN0.3g;

[0022] Step 2: Mix the above raw materials separately and stir them with a mixer for 5 minutes to make them evenly stirred;

[0023] Step 3: Then inject it into the mold separately, and cure the reaction mixture by thermal initiation;

[0024] Step 4: Then demould separately to remove unreacted monomers or oligomers to obtain a hydrogel material.

[0025] Performance Testing:

[0026] Dry the above-mentioned hydrogel material at 100°C for 5 hours, then place it in a cooling device for cooling, measure its weight, and obtain the first weight, which is 145.62g; ...

Embodiment 2

[0028] A hydrogel material with a water content of 50%-60%, which is prepared by the following method:

[0029] Step 1: Prepare raw materials according to the following weight: hydrophilic comonomer 2-hydroxyethyl methacrylate HEMA131.04g, hydrophilic substance 2-methacryloyloxyethylphosphorylcholine MPC13.33g, crosslinking agent two Ethylene glycol methacrylate EGDMA1.2g, initiator azobisisobutyronitrile AIBN0.3g;

[0030] Step 2-step 4 is identical with embodiment 1;

[0031] The experimental environment of the performance test part is the same as that of Example 1. The measured first weight is 145.87g, the second weight is 220.44g, the moisture content is 51.12%, and the adsorption capacity per unit area is 3.8μg / cm 2 .

Embodiment 3

[0033] A hydrogel material with a water content of 50%-60%, which is prepared by the following method:

[0034] Step 1: Prepare raw materials according to the following weights: hydrophilic comonomer 2-hydroxyethyl methacrylate HEMA129.62g, hydrophilic substance 2-methacryloyloxyethylphosphorylcholine MPC14.24g, crosslinking agent two Ethylene glycol methacrylate EGDMA1.2g, initiator azobisisobutyronitrile AIBN0.3g;

[0035] Step 2-step 4 is identical with embodiment 1;

[0036] The experimental environment of the performance test part is the same as that of Example 1. The measured first weight is 145.36g, the second weight is 220.92g, the moisture content is 51.98%, and the adsorption capacity per unit area is 3.6μg / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com