Micro-branched micro-cross-linked association polymer, preparation method and applications thereof

A technology of associative polymers and micro-crosslinking, applied in the field of polymers, can solve problems such as poor temperature and salt resistance, and achieve the effect of enhancing temperature and salt resistance and improving temperature and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

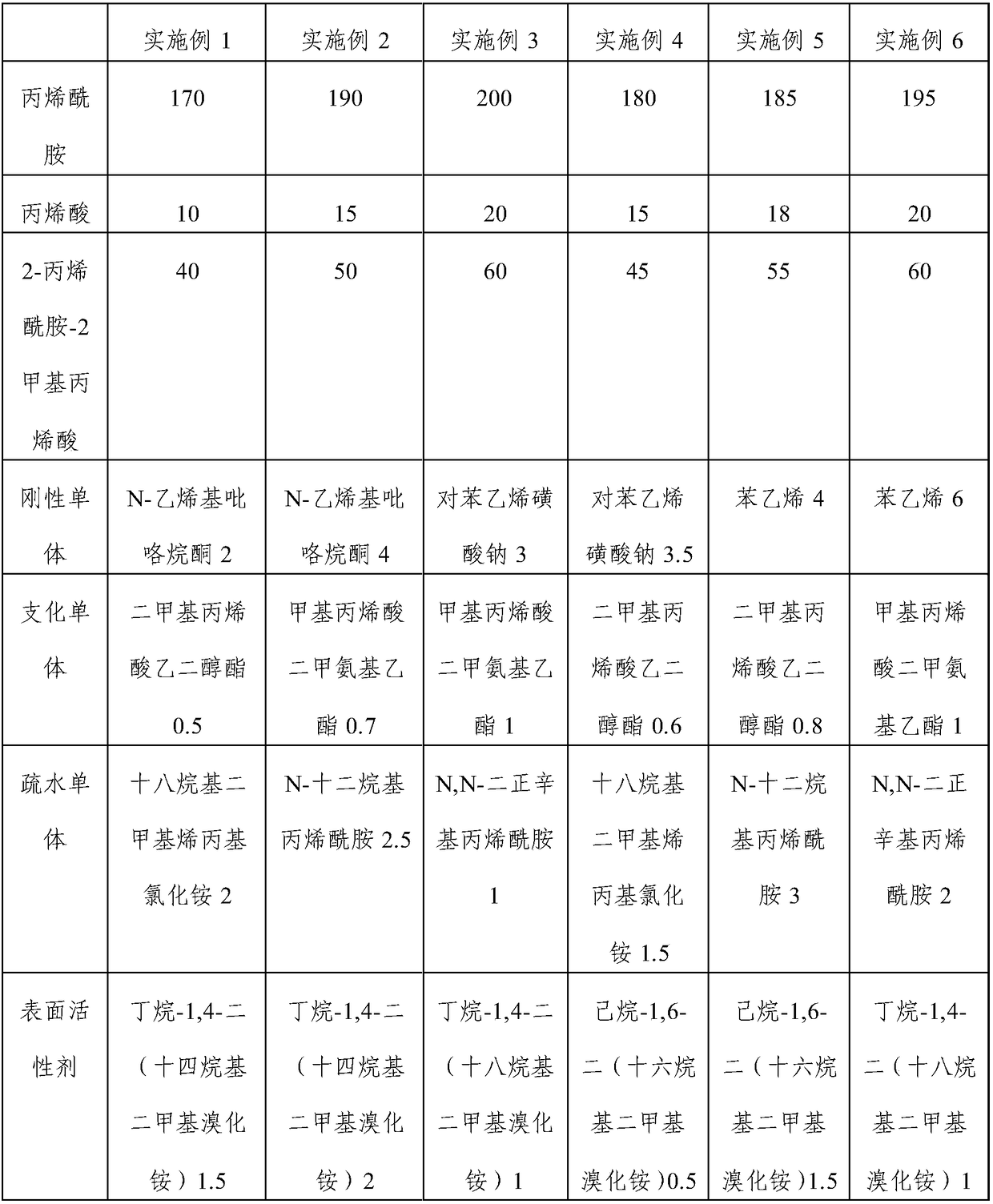

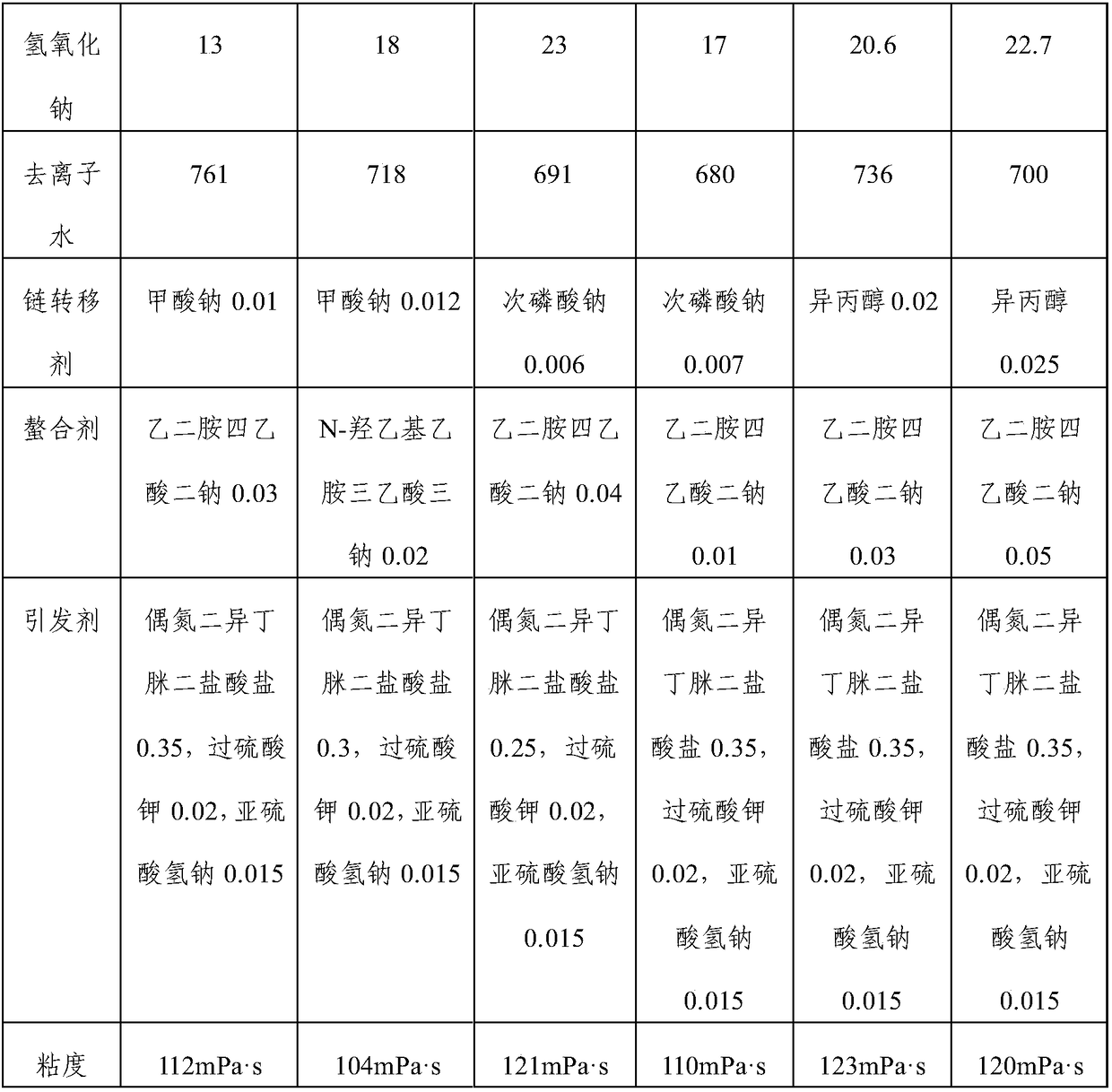

[0042] The invention provides a preparation method of a micro-branched micro-crosslinked associative polymer. The preparation raw materials include the following components: 170-200 parts by weight of acrylamide, 10-20 parts by weight of acrylic acid, 2-acrylamide-2-methanol 40-60 parts by weight of propanesulfonic acid, 2-6 parts by weight of rigid monomer, 0.5-1 part by weight of branched monomer, 1-3 parts by weight of hydrophobic monomer, 0.5-2 parts by weight of surfactant, 680-763 parts by weight of solvent parts by weight, 13-23 parts by weight of sodium hydroxide, 0.005-0.025 parts by weight of chain transfer agent, 0.01-0.05 parts by weight of chelating agent and 0.001-0.5 parts by weight of initiator. Described preparation method comprises the steps:

[0043](1) Initial mix: mix acrylamide, acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid, rigid monomer, branched monomer, hydrophobic monomer, surfactant and solvent. Wherein, the rigid monomer is selected from...

Embodiment 1

[0052] The preparation raw materials include the following components: 170 parts by weight of acrylamide, 10 parts by weight of acrylic acid, 40 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid, 2 parts by weight of N-vinylpyrrolidone, ethylene glycol dimethacrylate 0.5 parts by weight of ester, 2 parts by weight of octadecyldimethylallyl ammonium chloride, 1.5 parts by weight of butane-1,4-di(tetradecyldimethylammonium bromide), 13 parts by weight of sodium hydroxide Parts by weight, 761 parts by weight of deionized water, 0.01 parts by weight of sodium formate, 0.03 parts by weight of disodium edetate, 0.35 parts by weight of azobisisobutylamidine dihydrochloride, 0.02 parts by weight of potassium persulfate and hydrogen sulfite 0.015 parts by weight of sodium.

[0053] The preparation method comprises the following steps:

[0054] Add acrylamide, acrylic acid, octadecyldimethylallyl ammonium chloride, 2-acrylamide-2-methylpropanesulfonic acid, N-vinylpyrrolidon...

Embodiment 2

[0058] The preparation raw materials include the following components: 190 parts by weight of acrylamide, 15 parts by weight of acrylic acid, 50 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid, 4 parts by weight of N-vinylpyrrolidone, dimethylaminoethyl methacrylate 0.7 parts by weight of ester, 2.5 parts by weight of N-dodecylacrylamide, 2 parts by weight of butane-1,4-di(tetradecyldimethylammonium bromide), 18 parts by weight of sodium hydroxide, deionized 718 parts by weight of water, 0.012 parts by weight of sodium formate, 0.02 parts by weight of trisodium N-hydroxyethylethylamine triacetate, 0.3 parts by weight of azobisisobutylamidine dihydrochloride, 0.02 parts by weight of potassium persulfate and sodium bisulfite 0.015 parts by weight.

[0059] The preparation method comprises the following steps:

[0060] Add acrylamide, acrylic acid, N-dodecylacrylamide, 2-acrylamide-2-methylpropanesulfonic acid, N-vinylpyrrolidone, dimethylaminoethyl methacrylate, bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salinity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com