Preparation method and use of loofah sponge surface lead ion imprinted absorbing material

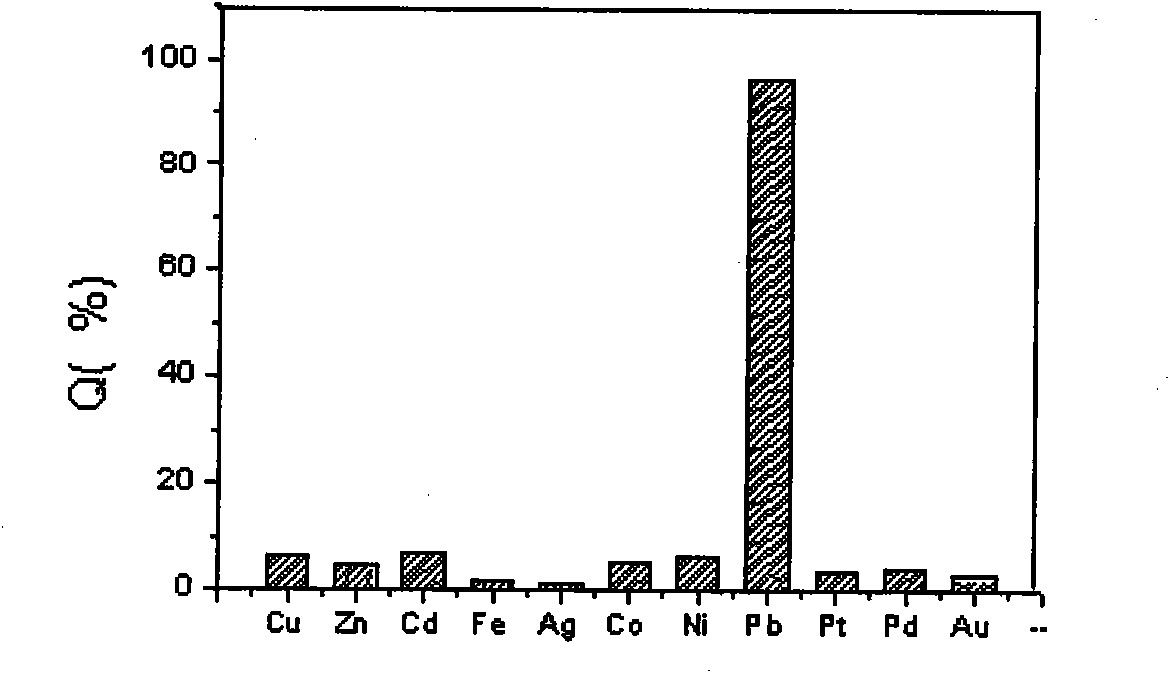

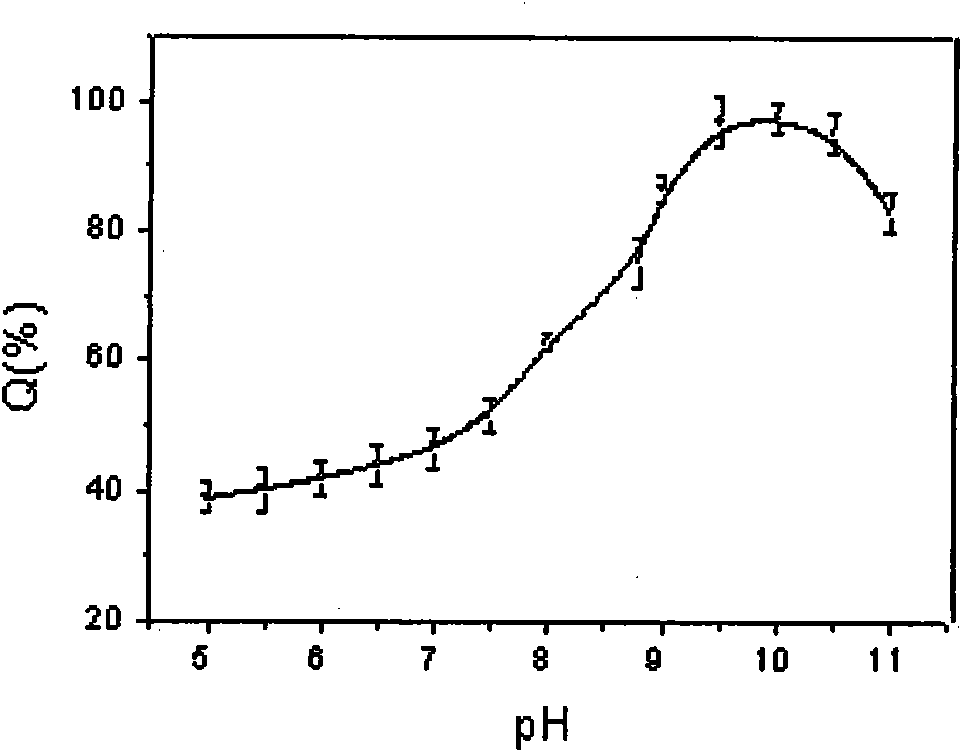

The technology of imprinting material and loofah is applied in the field of preparation and application of lead ion imprinted adsorption material on the surface of loofah, which can solve the problems of destroying the imprinting point, poor controllability, small adsorption capacity, etc. The effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Loofah pretreatment: loofah is derived from loofah fruit, which is obtained by peeling and removing the core, cutting loofah into small pieces, washing with water, drying in vacuum, crushing, and sieving with an 80-mesh sieve;

[0030] (2) the loofah that pulverizes is by 50% of gross mass, is that 5% NaOH solution and 20% ethanol solution are mixed and submerged azeotrope 0.5h with concentration, constantly adds NaOH solution and ethanol mixed solution during azeotropy, to keep The volume of the solution is constant, after cooling, it is washed with deionized water until the pH is 7, and after suction filtration, it is dried at 60° C. to obtain alkalized loofah.

[0031](3) Acylated loofah: In a stoppered Erlenmeyer flask, add 2 g of alkalized loofah and 40 mL of chloroform, stir for 10 min under the protection of argon, and add 2 mL of acryloyl chloride dropwise with a constant pressure funnel. Stir for 10 min after dropping, and then add 3.5 mL of triethylamine d...

Embodiment 2

[0036] (1) Loofah pretreatment: loofah is derived from loofah fruit, which is obtained by peeling and removing the core, cutting loofah into small pieces, washing with water, drying in vacuum, crushing, and sieving with an 80-mesh sieve;

[0037] (2) the loofah that pulverizes is by 50% of gross mass, is that 5% NaOH solution and 20% ethanol solution are mixed and submerged azeotrope 0.5h with concentration, constantly adds NaOH solution and ethanol mixed solution during azeotropy, to keep The volume of the solution is constant, after cooling, it is washed with deionized water until the pH is 7, and after suction filtration, it is dried at 60° C. to obtain alkalized loofah.

[0038] (3) Acylated loofah: In a stoppered Erlenmeyer flask, add 2 g of alkalized loofah and 40 mL of chloroform, stir for 10 min under the protection of argon, and add 2 mL of acryloyl chloride dropwise with a constant pressure funnel. Stir for 10 min after dropping, and then add 3.5 mL of triethylamine ...

Embodiment 3

[0043] (1) Loofah pretreatment: loofah is derived from loofah fruit, which is obtained by peeling and removing the core, cutting loofah into small pieces, washing with water, drying in vacuum, crushing, and sieving with an 80-mesh sieve;

[0044] (2) the loofah that pulverizes is by 50% of gross mass, is that 5% NaOH solution and 20% ethanol solution are mixed and submerged azeotrope 0.5h with concentration, constantly adds NaOH solution and ethanol mixed solution during azeotropy, to keep The volume of the solution is constant, after cooling, it is washed with deionized water until the pH is 7, and after suction filtration, it is dried at 60° C. to obtain alkalized loofah.

[0045] (3) Acylated loofah: In a stoppered Erlenmeyer flask, add 2 g of alkalized loofah and 40 mL of chloroform, stir for 10 min under the protection of argon, and add 2 mL of acryloyl chloride dropwise with a constant pressure funnel. Stir for 10 min after dropping, and then add 3.5 mL of triethylamine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com