Method for preparing apiolin molecularly imprinted polymer

A technology of molecular imprinting and apigenin, which is applied in chemical instruments and methods, other chemical processes, etc., can solve the problems related to the undiscovered molecular imprinting polymer of apigenin, and achieve remarkable molecular recognition ability, broad application prospect, good heat The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

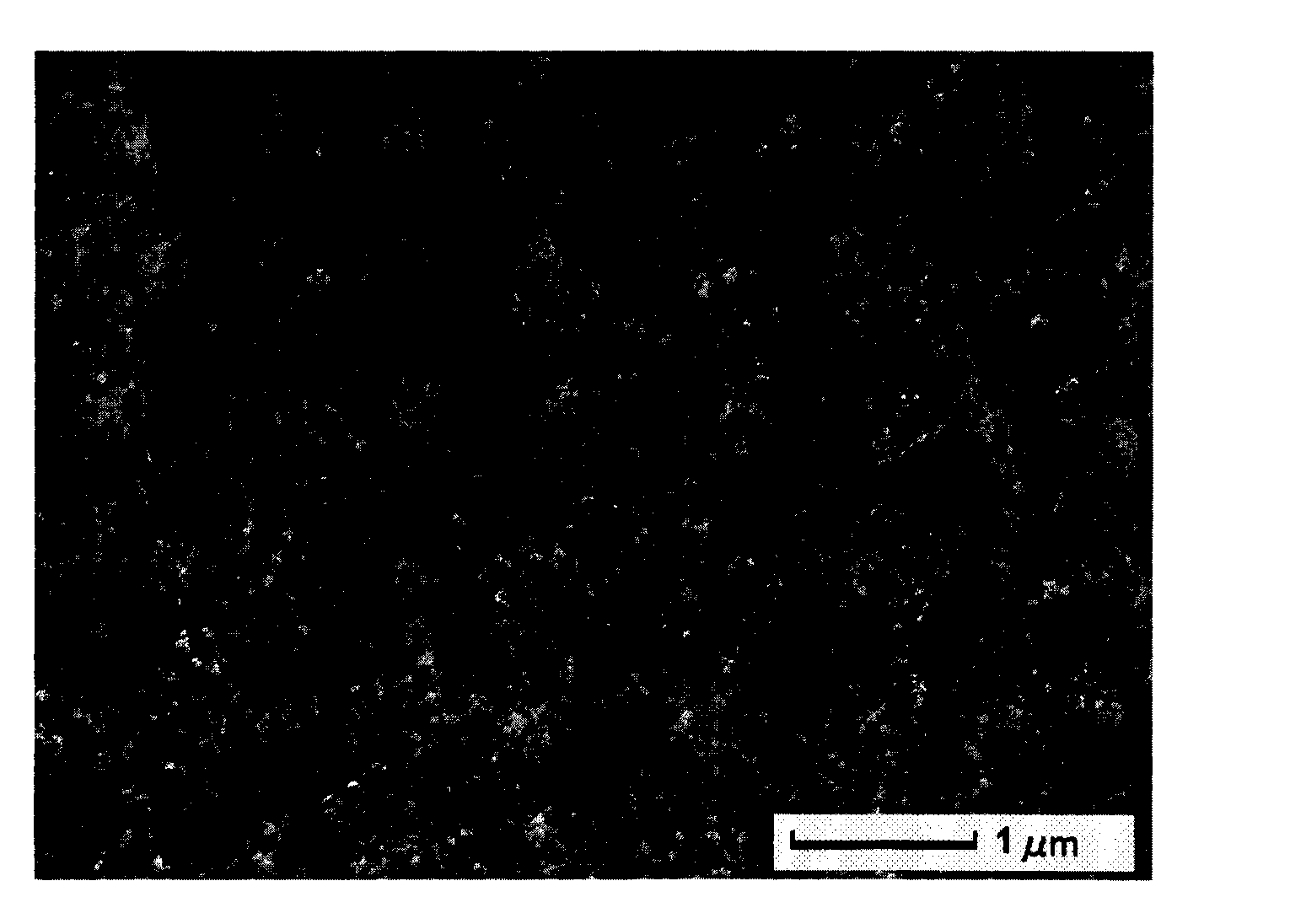

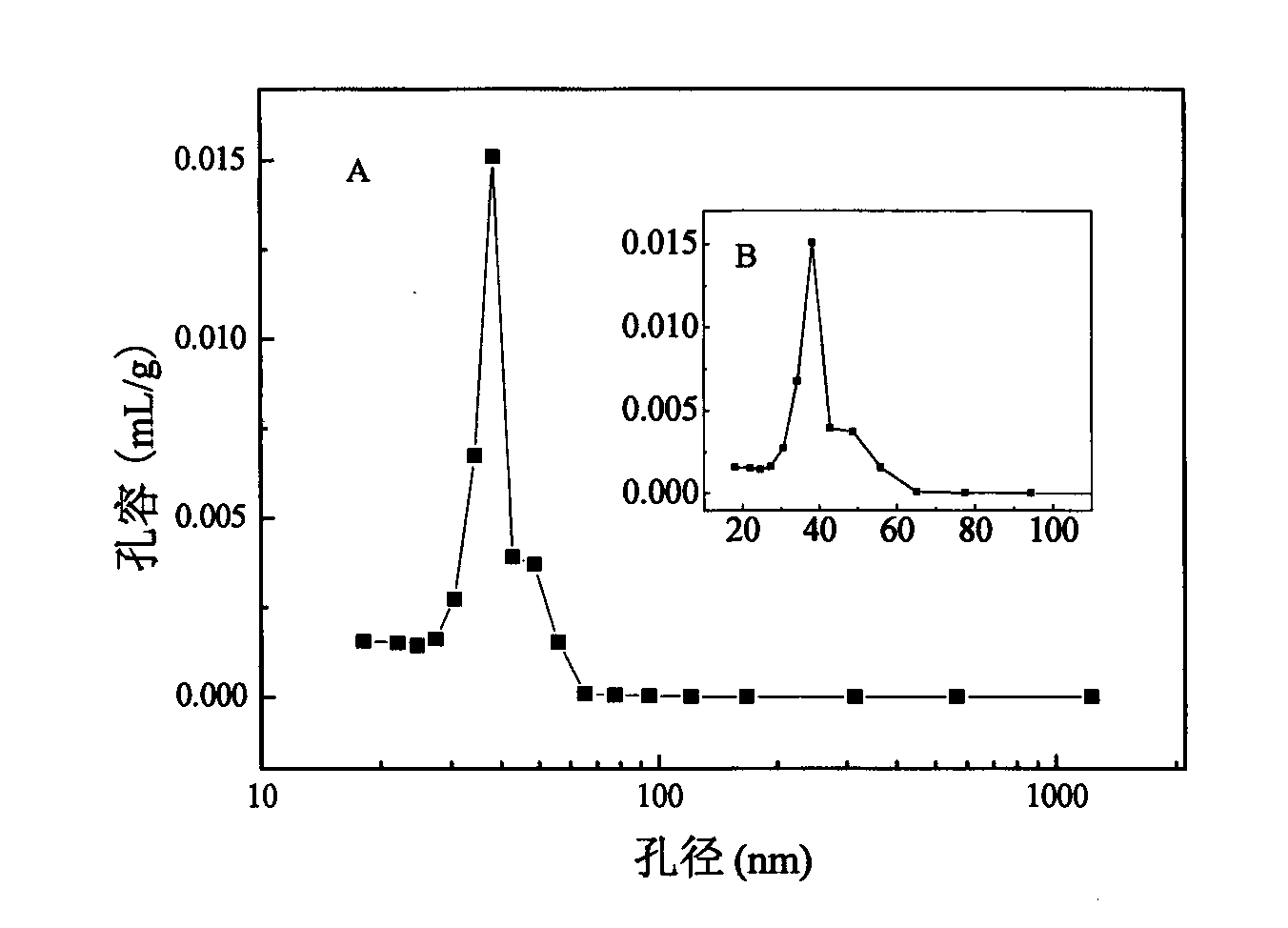

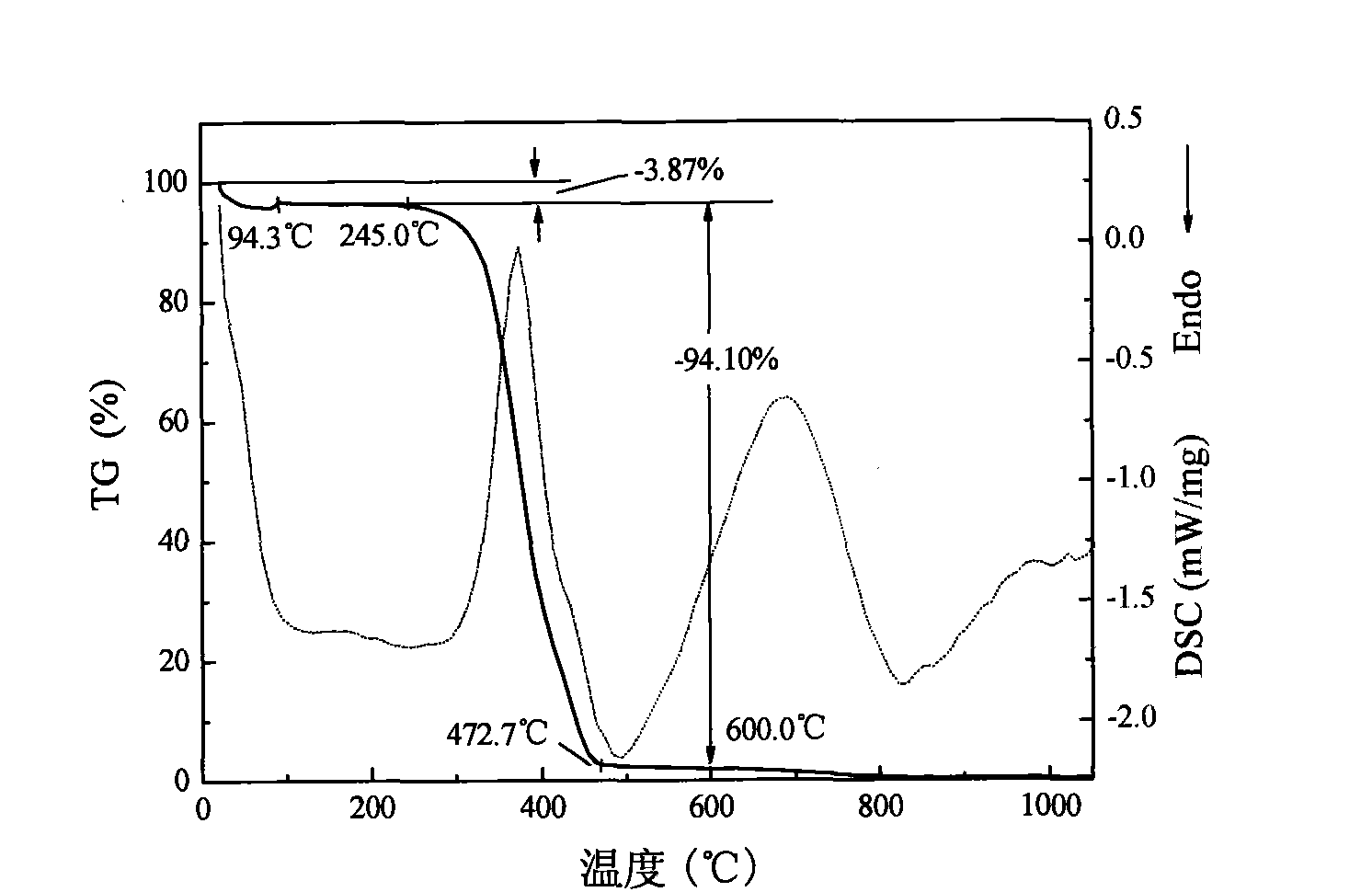

example 1

[0023] Dissolve 0.5mmol template molecule apigenin and 4mmol functional monomer 2-vinylpyridine into 20.0mL porogen tetrahydrofuran to prepare a mixed solution, shake at constant temperature and avoid light for 6h, add cross-linking agent ethylene glycol dimethacrylate 20mmol, initiator azobisisobutyronitrile (the amount is 1% of the mass of the monomer and crosslinking agent), fully miscible, degassed by ultrasonic for 15min, deoxygenated by nitrogen for 15min, and sealed the tube under vacuum. React in a water bath at 60°C for 24 hours to obtain a rod-shaped solid polymer. The prepared polymer was ground and passed through a 180-mesh sieve, fine particles were removed by acetone sedimentation three times, and dried to constant weight. The mixed solution of methanol and acetic acid with a volume ratio of 6:4 was used as the extraction solution, and the polymer was Soxhlet extracted for 72 hours, and the template molecules were removed, and then washed with pure methanol for 3...

example 2

[0025] Dissolve 0.5mmol template molecule apigenin and 2mmol functional monomer acrylamide into 20.0mL porogen tetrahydrofuran to prepare a mixed solution, shake at constant temperature and avoid light for 6h, add 10mmol cross-linking agent ethylene glycol dimethacrylate, trigger Azobisisobutyronitrile (the amount used is 1% of the mass of the monomer and cross-linking agent), after fully miscible, ultrasonic degassed for 20 minutes, deoxygenated with nitrogen for 15 minutes, and the tube was sealed under vacuum. React in a water bath at 60°C for 24 hours to obtain a rod-shaped solid polymer. The prepared polymer was ground and passed through a 180-mesh sieve, fine particles were removed by acetone sedimentation three times, and dried to constant weight. The mixed solution of methanol and acetic acid with a volume ratio of 6:4 was used as the extraction solution, and the polymer was Soxhlet extracted for 72 hours, and the template molecules were removed, and then washed with p...

example 3

[0027] Dissolve 0.5mmol template molecule apigenin and 4mmol functional monomer 2-vinylpyridine into 20.0mL porogen tetrahydrofuran to prepare a mixed solution, shake at constant temperature and avoid light for 6h, add cross-linking agent ethylene glycol dimethacrylate 28mmol, initiator azobisisobutyronitrile (the amount is 1% of the mass of the monomer and the crosslinking agent), after fully miscible, ultrasonic degassing for 20 minutes, nitrogen deoxygenation for 15 minutes, and sealing the tube under vacuum. React in a water bath at 60°C for 24 hours to obtain a rod-shaped solid polymer. The prepared molecularly imprinted polymer was ground and passed through a 180-mesh sieve, fine particles were removed by acetone sedimentation three times, and dried to constant weight. The mixed solution of methanol and acetic acid with a volume ratio of 6:4 was used as the extraction solution, and the polymer was Soxhlet extracted for 72 hours, and the template molecules were removed, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com