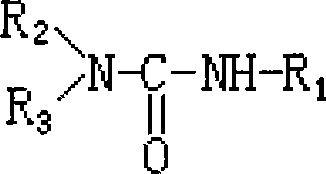

Preparation method of solid-phase extraction small column for molecular imprinting of substituted carbamide pesticide

A solid-phase extraction column and molecular imprinting technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as incomplete purification, inability to separate and retain, and inability to enrich the components to be tested, and achieve high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of molecularly imprinted polymer microspheres of substituted urea pesticides

[0031] (1). The molar ratio of template molecule, functional monomer and crosslinking agent is 1:2; the volume ratio of the total volume of diluent and crosslinking agent to water is 1:10; the concentration of polyvinyl alcohol 400 (PVA400) 4%; 8mmoL functional monomer methacrylic acid and 1mmol template molecular substituted urea pesticides were dissolved in the diluent, and ultrasonically acted for 5min; 40mmoL crosslinking agent ethylene glycol dimethacrylate (EGDMA), 120mg initiator (AIBN) and 15mL diluent were mixed, sonicated for 5-10min; the above three solutions were mixed, degassed by sonication for 5min; stirred at a constant temperature of 350rpm at 60°C for 20h;

[0032] (2). Stir the molecularly imprinted polymer microspheres prepared by the above reaction in 80°C water for 60 minutes, then cool down and filter, wash with double distilled water 3 times after filtr...

Embodiment 2

[0045] (1) Preparation of molecularly imprinted polymer microspheres of substituted urea pesticides

[0046](1). The molar ratio of template molecule, functional monomer and crosslinking agent is 1: 4; the volume ratio of the total volume of diluent and crosslinking agent to water is 1: 8; the concentration of polyvinyl alcohol 400 is 4 %; 8mmol functional monomer methacrylic acid and 1mmol template molecule substituted urea pesticides were dissolved in the diluent, and ultrasonicated for 5-10min; 5mL cross-linking agent ethylene glycol dimethacrylate (EGDMA), 120mg initiator (AIBN) and 15mL of diluent were mixed, sonicated for 5-10min; the above three solutions were mixed, and stirred at a constant temperature of 400rpm at 60°C for 22h;

[0047] (2). Stir the molecularly imprinted polymer microspheres prepared by the above reaction in 80°C water for 60 minutes, then cool down and filter, wash with double distilled water 3 times after filtration, wash 3 times with 20mL methano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com